Testing device for flat knitting machine shaking table complete set screw rod moving clearance

A technology of a flat knitting machine and a testing device is applied in the field of knitting machinery to achieve the effects of ensuring reliability, ensuring safe operation and convenient reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

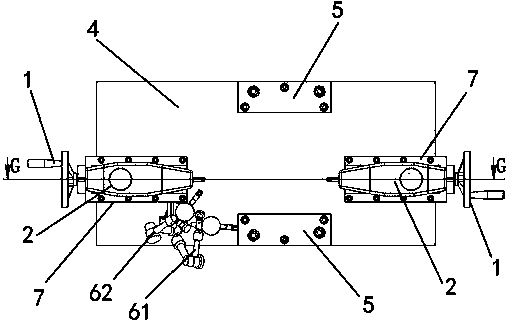

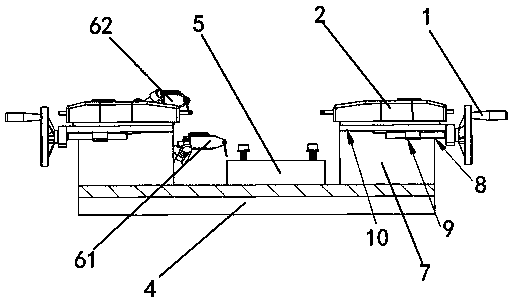

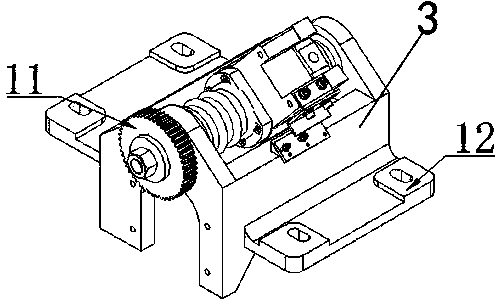

[0016] See attached picture. This embodiment includes a base 4, a complete set of fixing mechanism for a shaking table, a sliding seat mechanism and a testing mechanism. The complete fixing mechanism, a sliding seat mechanism and a testing mechanism for a shaking table are all installed on the base 4; mechanism, and tested by the measuring mechanism; the complete set of shaking table fixing mechanism includes two fixing seats 5 and a complete set of shaking table 3, and the two fixing seats 5 are respectively fixed at the front and rear positions of the base 4, and the complete set of shaking table 3 is provided with A threaded rod pulley 11, the front and rear side walls of the shaker complete set 3 are provided with a shaker complete set base 12, and the shaker complete set base 12 is respectively fixed on the front and rear two fixing seats 5 by screws, so that the shaker complete set The complete set 3 is fixed between the front and rear two fixing seats 5 .

[0017] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com