A connector for wiper

A connector and wiper technology, which is applied to the parts, connections, electrical components and other directions of the connection device, can solve the problems of bending and deformation of the lug, contact between the lug and the lining plate or insufficient safety clearance, and short-circuit fault of the wiper motor. , to achieve the effect of safety clearance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

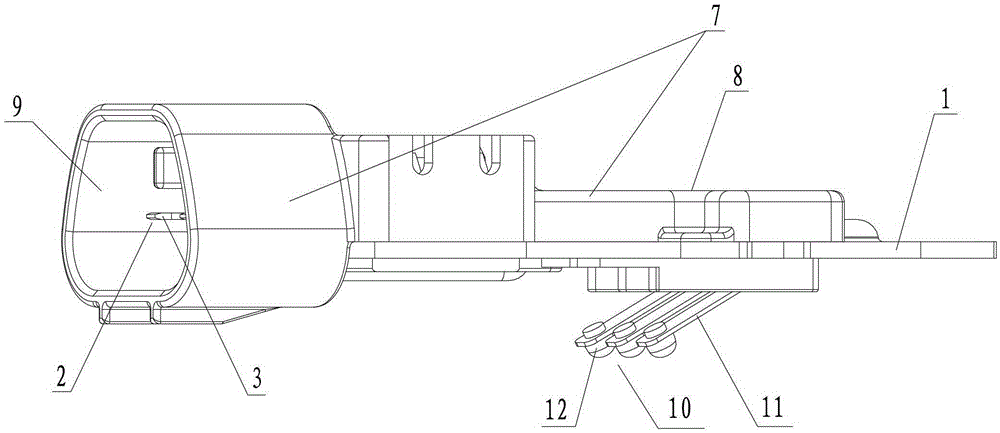

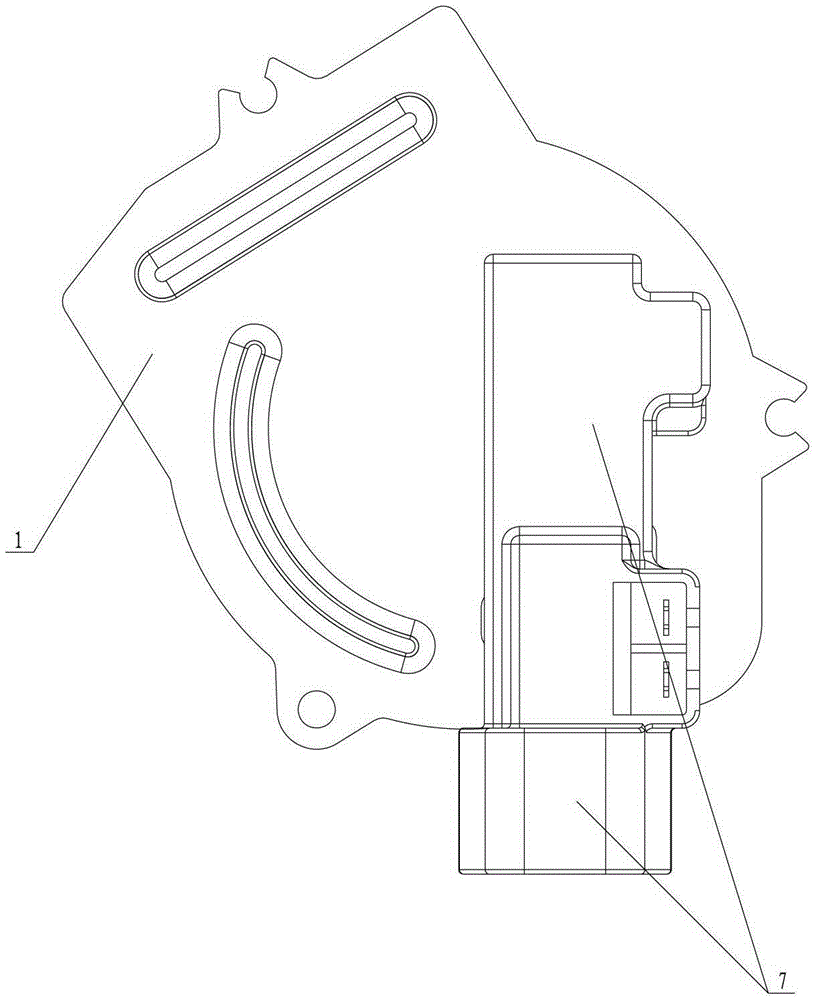

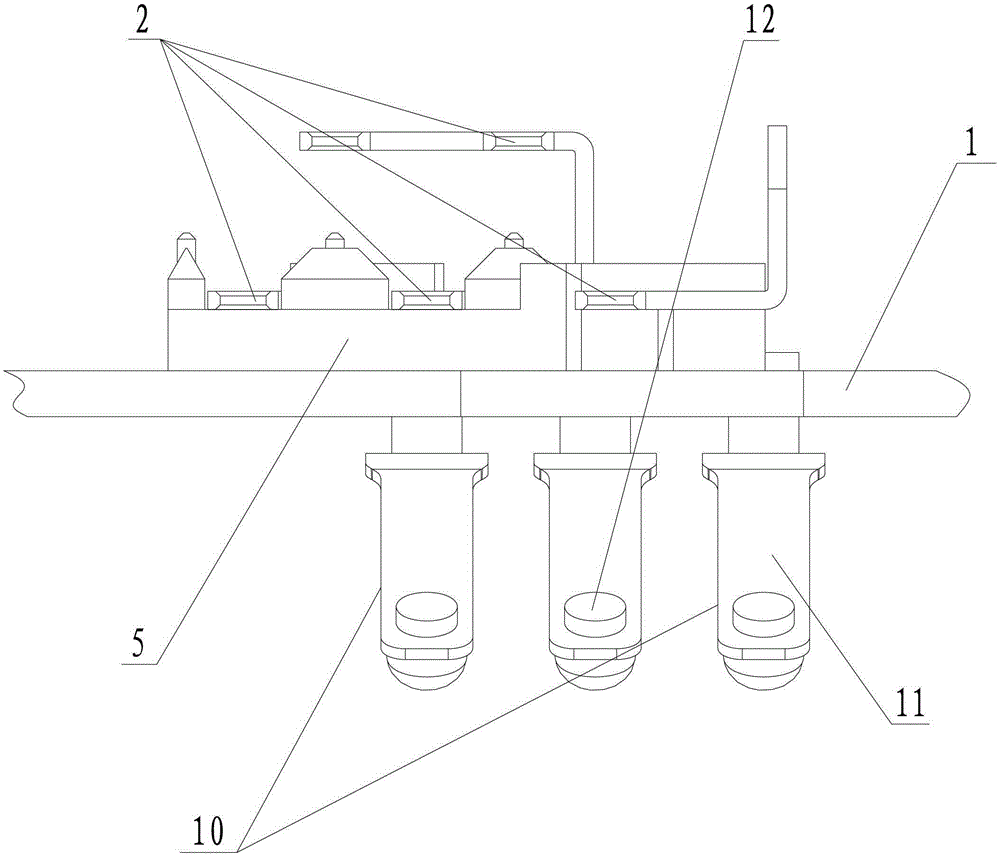

[0019] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is a connector for a wiper that can effectively guarantee the safety gap between the lug and the inner liner provided by the present invention. The connector includes an inner liner 1 and at least two lugs 2 on the inner liner 1, each of the lugs 2 has a plug end 3 and a contact end 4, the The plug-in end 3 is located on the upper side of the inner lining board 1, and the contact end 4 is located on the lower side of the inner lining board 1 after passing through the inner lining board 1, between the inner lining board 1 and the inner lining board 1 There is an injection molded isolation layer between the wiring pieces 2, and also includes a positioning spacer 5, and each piece of the wiring piece 2 is supported on the upper side of the inner liner 1 through the positioning spacer 5. Since each piece of lug 2 is supported on the upper side of the inner liner 1 through the positioning spacer 5 . In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com