Rod unloading car

A technology for unloading a bar car and a car body, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of easy tilting of silicon wafers, increase production costs, and damage to silicon wafers, so as to avoid damage caused by collisions and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

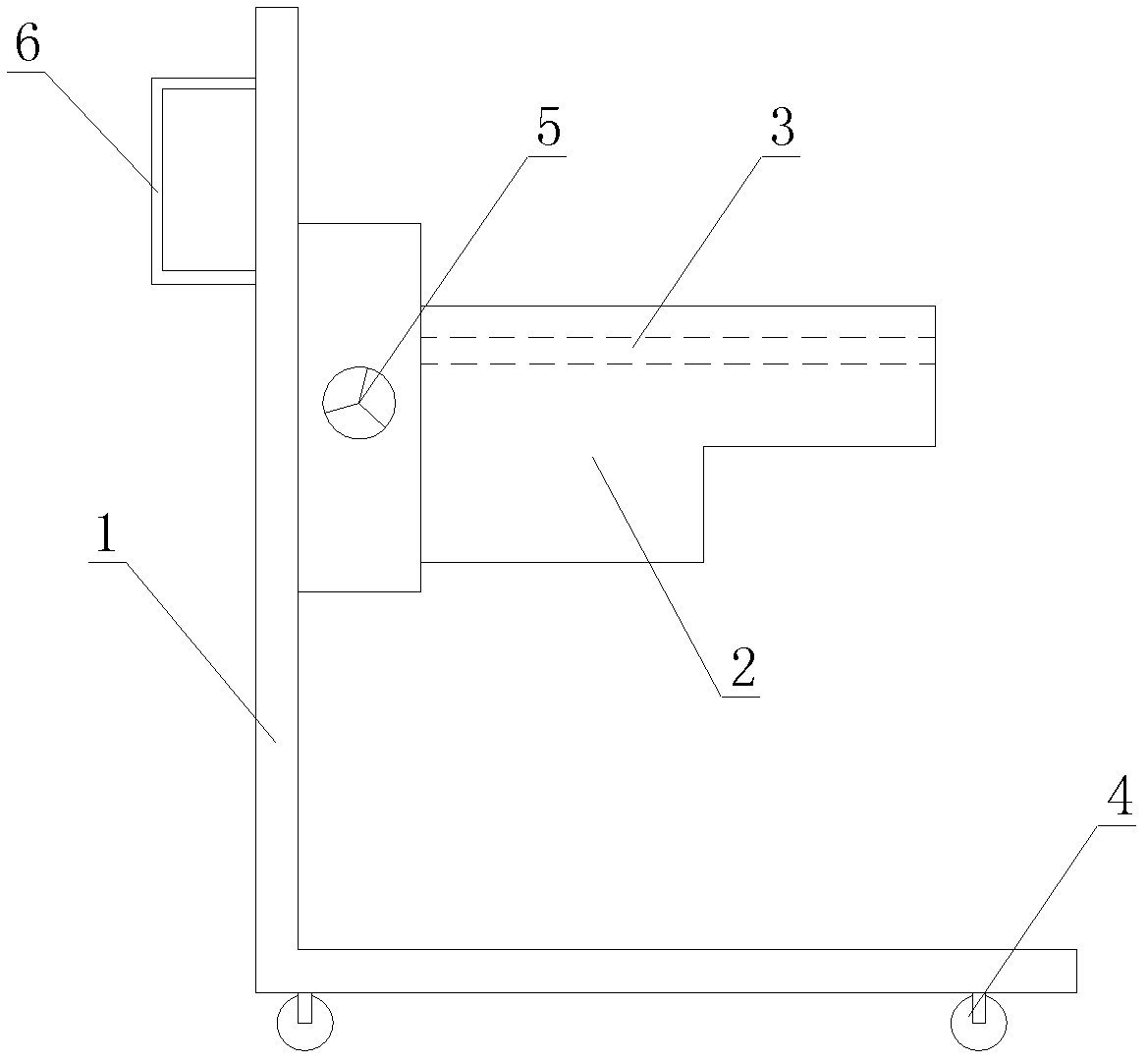

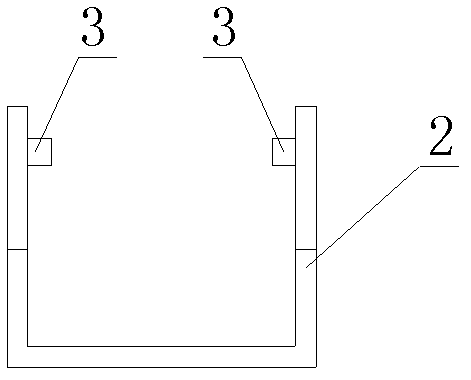

[0013] Such as figure 1 and figure 2 As shown, a rod unloading vehicle includes a vehicle body 1 and a bracket 2 arranged on the vehicle body 1, and a pair of symmetrical guiding and positioning strips 3 are provided on the inner walls of both sides of the bracket 2 . The guide positioning bar 3 limits the stacked silicon wafers in the bracket 2, ensuring a safe gap between the inner side wall of the bracket and the stacked silicon wafers, and avoiding the collision between the tilted silicon wafer and the inner side wall of the bracket. damage, reducing production costs. The bottom of the car body 1 is provided with an automatic locking pulley 4 . The vehicle body 1 is provided with a discharge control device 5 corresponding to the bucket 2 . The vehicle body 1 is provided with a handle 6 . Two pairs of guide and positioning strips 3 can also be used, which are respectively symmetrically arranged on the upper and lower parts of the inner side walls on both sides of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com