Tire vulcanization mold and manufacturing method therefor

A technology of tire vulcanization and manufacturing method, which is applied to household appliances, other household appliances, tires, etc., can solve problems such as inability to ensure stable exhaust, tire vulcanization failure, blade shedding, etc., to prevent tire vulcanization failure, stable exhaust, Ensure the effect of exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

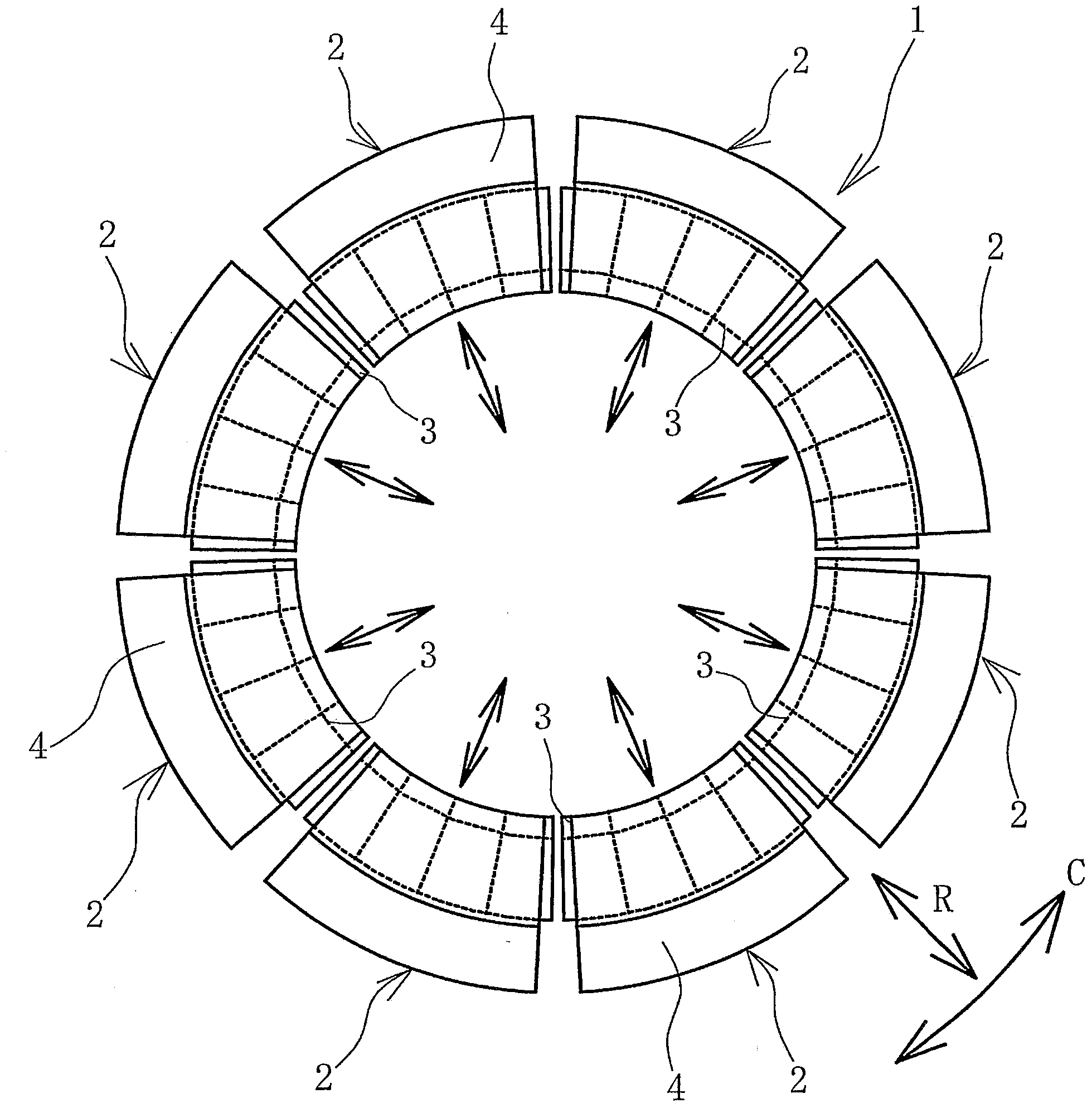

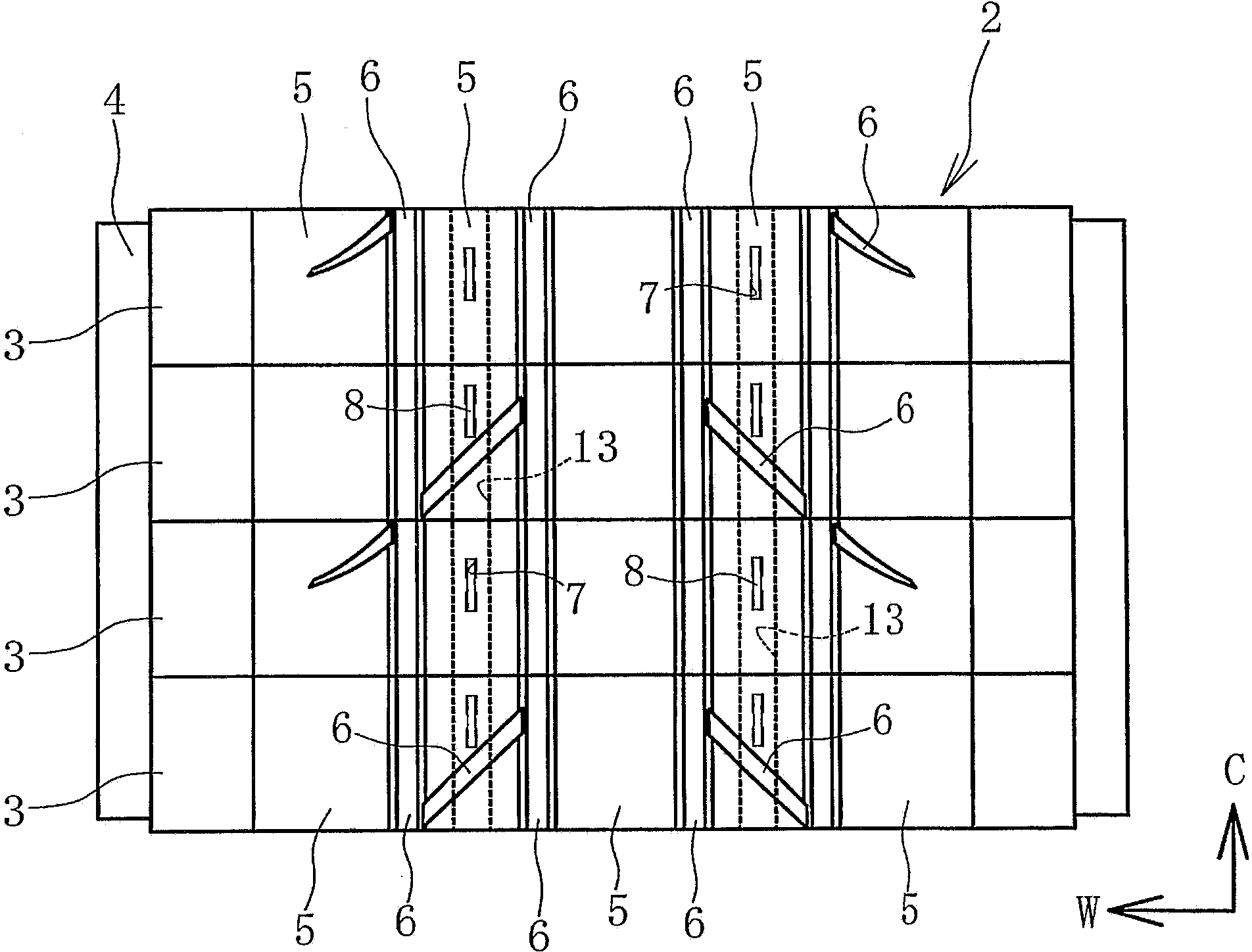

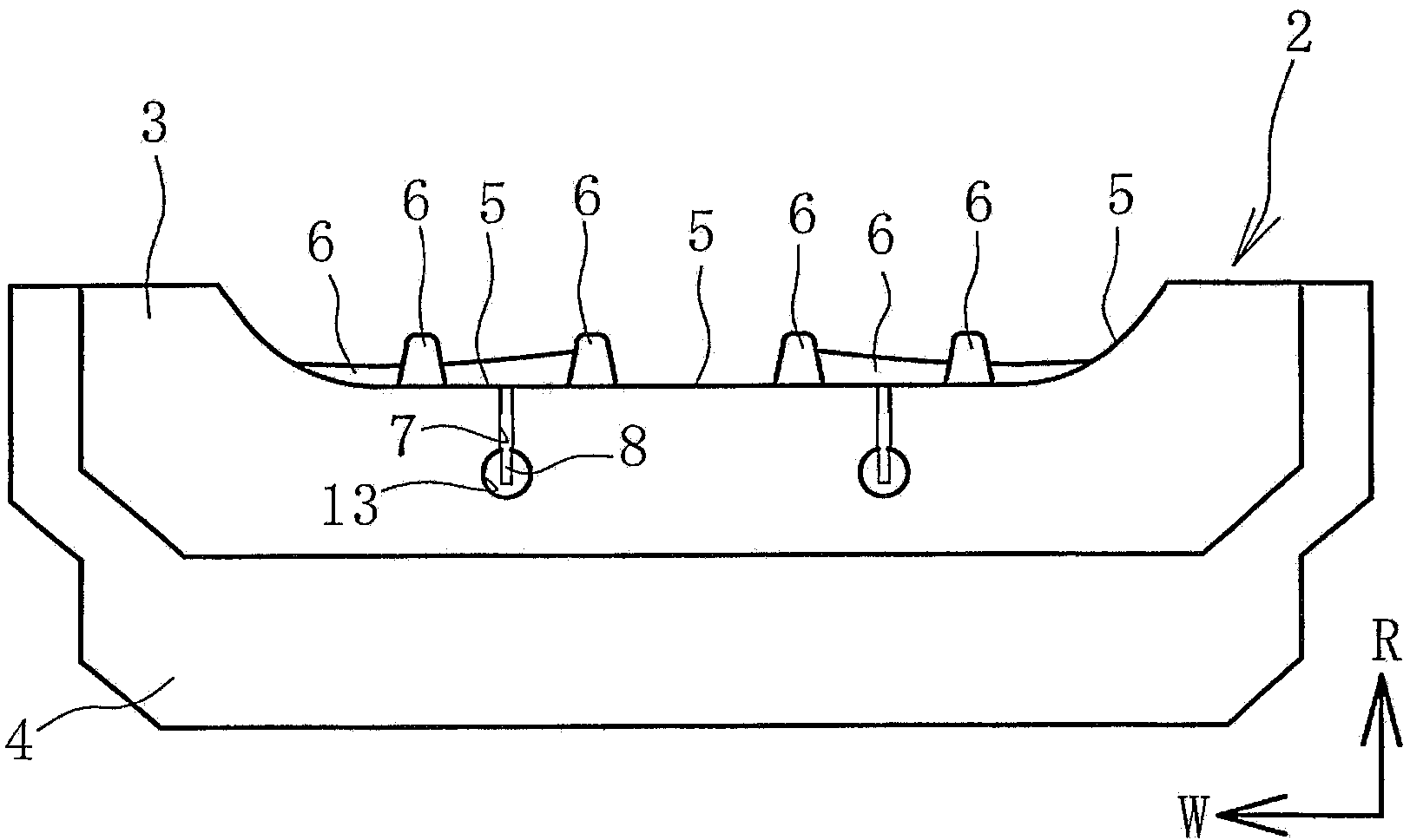

[0035] Hereinafter, the mold for tire vulcanization and its manufacturing method according to the present invention will be described based on the embodiments shown in the drawings. Figure 1 ~ Figure 3 Arrows C, R, and W described in , indicate the circumferential direction, radial direction, and width direction of the raw tire inserted into the vulcanization mold for vulcanization, respectively.

[0036] Such as figure 1 As shown, the mold 1 for tire vulcanization of the present invention (hereinafter referred to simply as the mold 1 ) is a segmented type formed by assembling a plurality of arcuate sector blocks 2 into a ring shape. Such as figure 2 , image 3 As shown, each sector block 2 is composed of a liner 4 and a plurality of parts 3 , and two adjacent parts 3 are installed on the liner 4 in a state of close contact.

[0037] Each sector block 2 forming a ring moves forward and backward relative to the center of the ring. The inner peripheral surface of each memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com