Lead-acid storage battery maintenance method

A technology of lead-acid battery and storage battery, which is applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery repair/maintenance, etc. It can solve the problems of decreased insulation performance, short battery life, and shortened battery life, so as to prevent vulcanization Effect of invalidation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

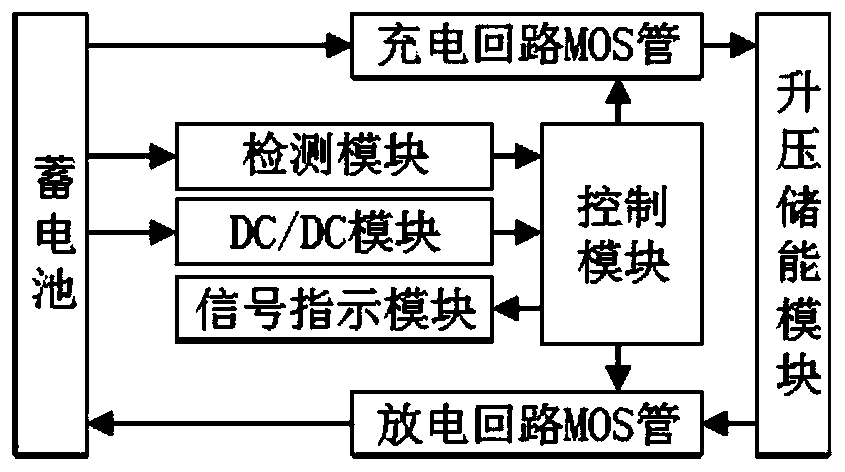

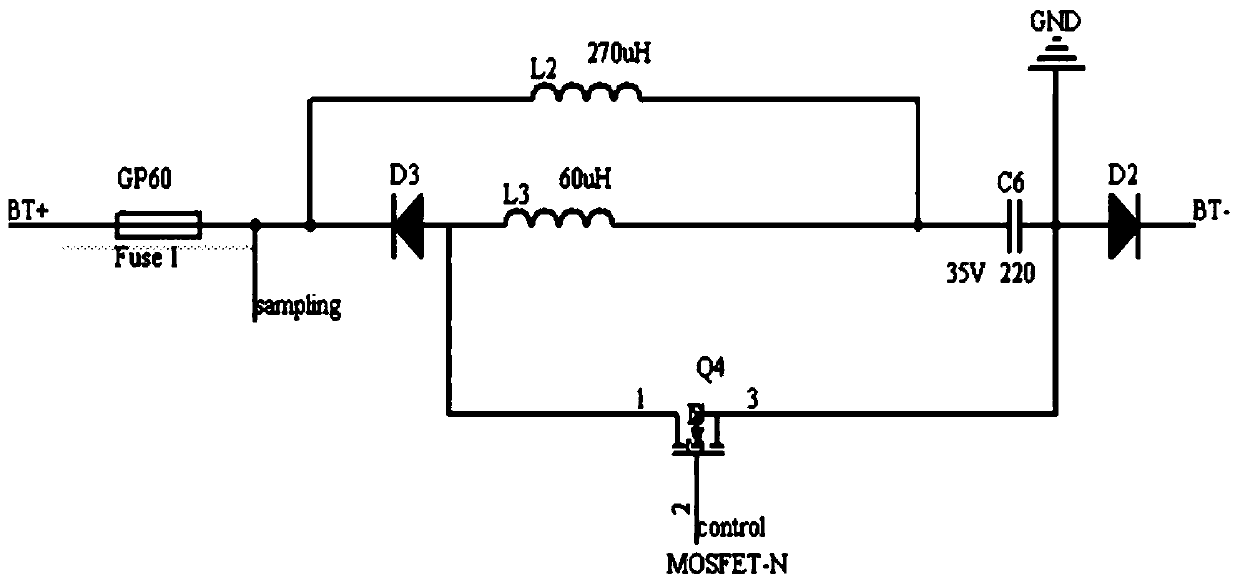

[0027] Such as figure 1 As shown, this embodiment is a self-maintenance method for a lead-acid battery. By applying a charge-discharge pulse of a certain frequency to the battery, this charge-discharge pulse keeps the active material inside the battery in an activated state and can break the PbSO 4 Conditions for crystallization can prevent lead-acid batteries from vulcanization failure and prolong the service life of batteries.

[0028] The principle of self-maintenance of lead-acid batteries: sulfur ions have 5 different energy levels, and the ions in the metastable energy level tend to migrate to the stable covalent bond energy level. Sulfur in a stable covalent bond energy level exists in the form of a ring molecule containing 8 atoms. The 8-atom ring molecular mode is a relatively stable combination that is difficult to jump and be broken. PbSO 4 The sulfur atom in the crystal is in this stable energy level state. To break the structure of these sulfide layers, it is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com