Pneumatic tire and method for manufacturing same

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, reinforcing layers of pneumatic tires, tire parts, etc., and can solve problems such as reducing the amount of joint rubber layer, affecting tire manufacturability, and increasing the number of ends, so as to reduce rolling. Effects of resistance, prevention of vulcanization failure, and weight reduction of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

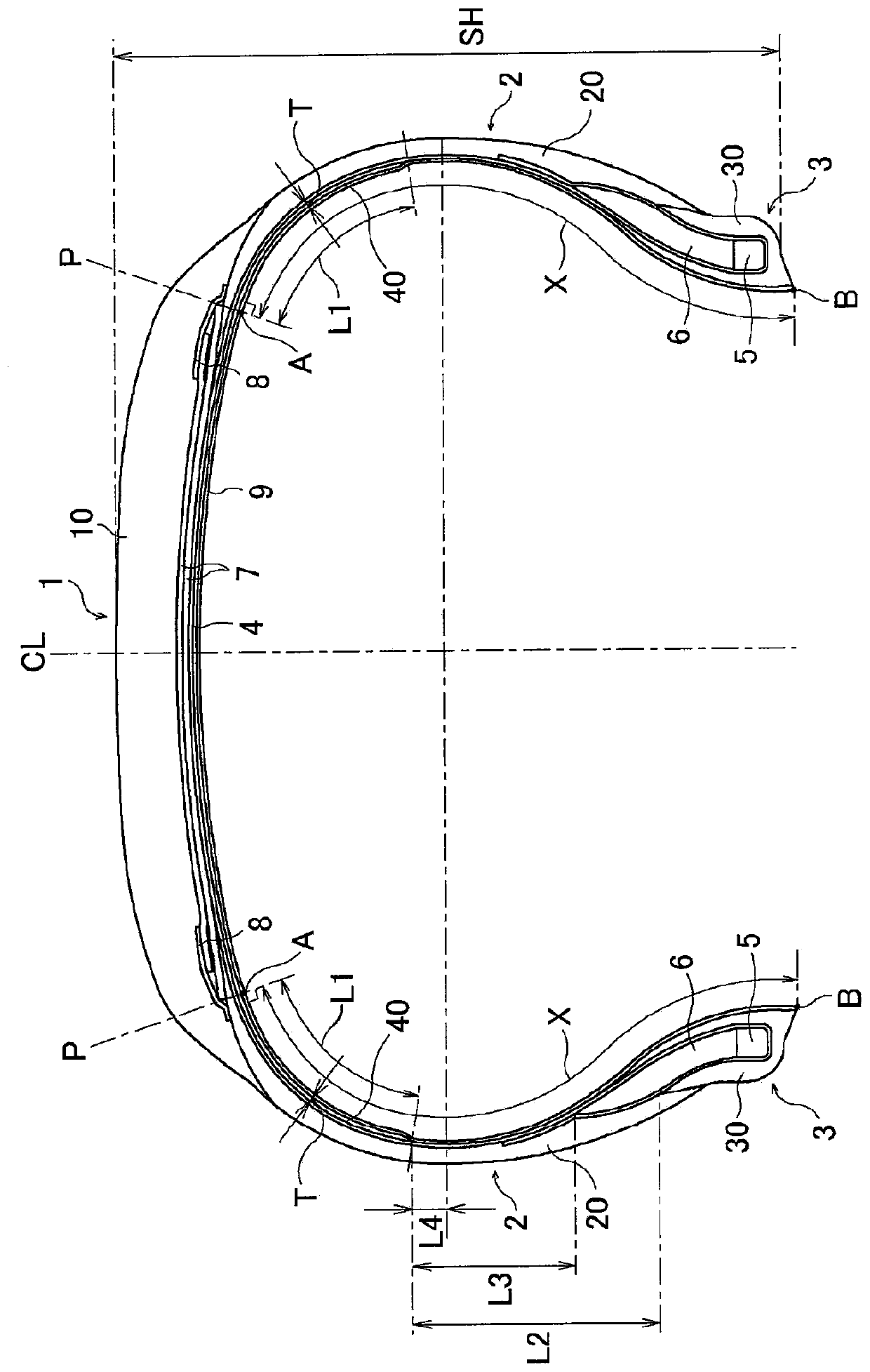

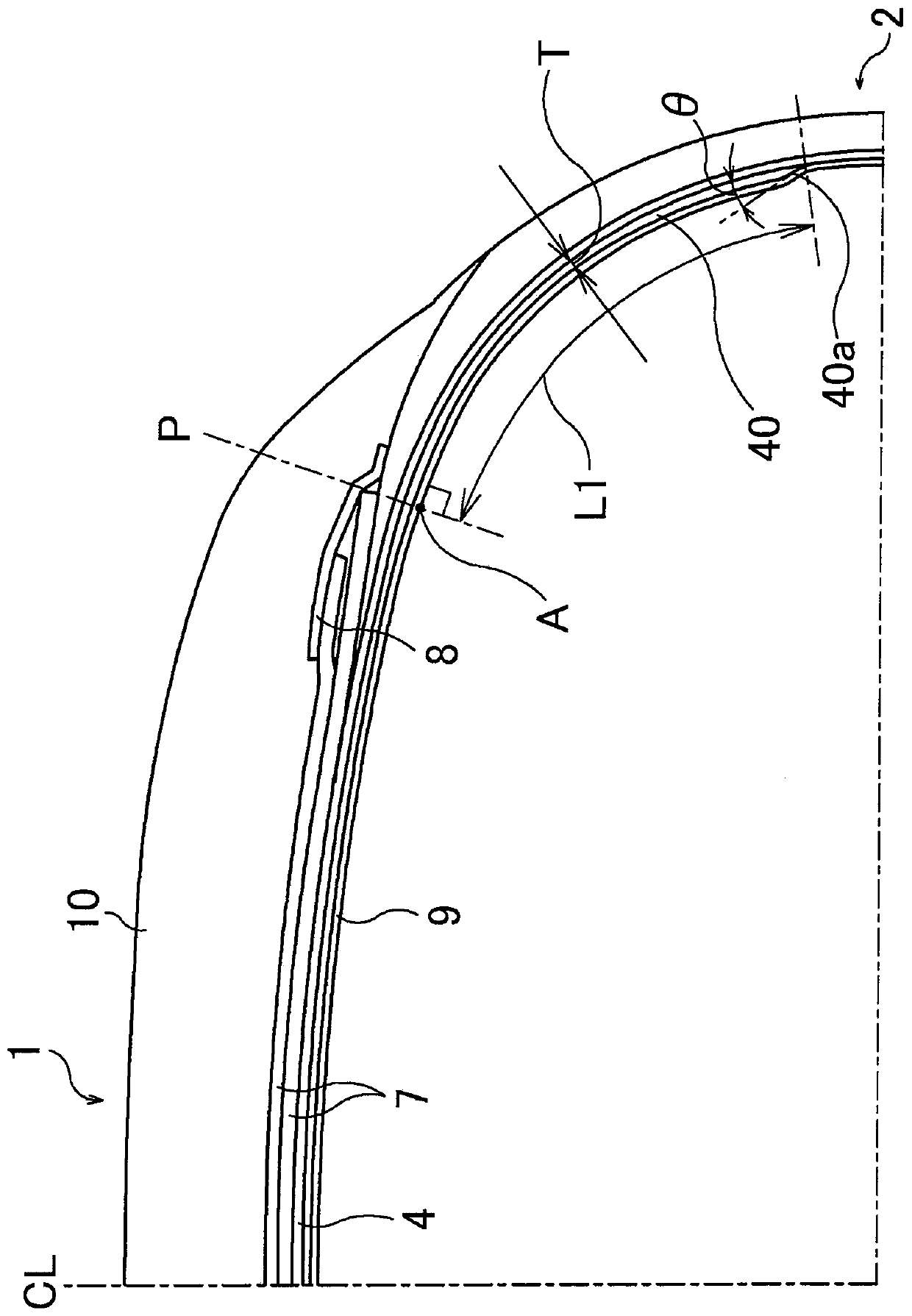

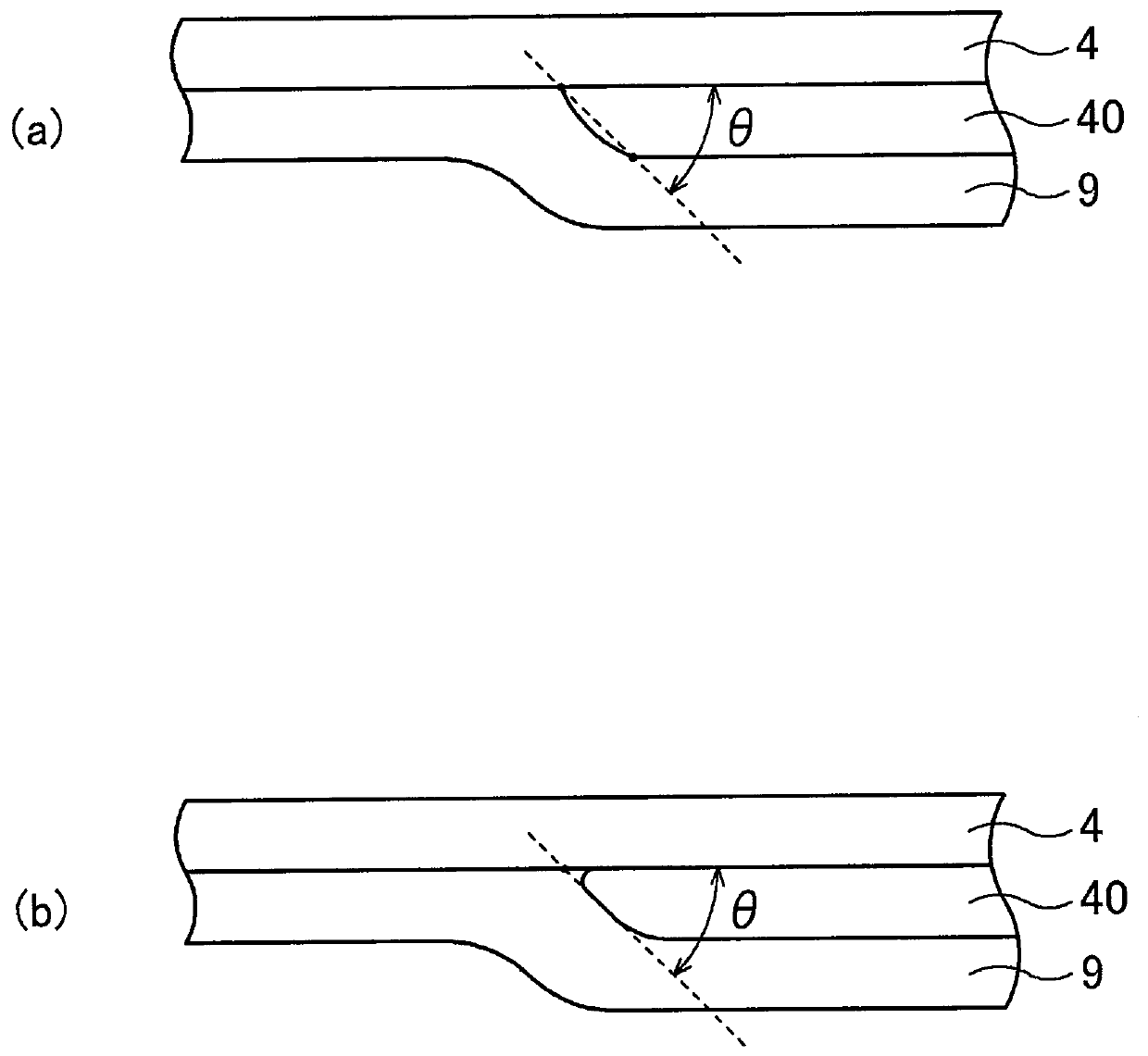

[0044] 24 pneumatic tires of conventional example 1, comparative examples 1 to 4, and examples 1 to 19 were produced, wherein the tire size was 195 / 65R15, with figure 1 The basic structure shown, the structure of the joint rubber layer, the inclination angle θ of the inclined surface formed at the end of the partial joint rubber layer, the rubber hardness of the partial joint rubber layer, the rubber thickness of the partial joint rubber layer, the partial joint rubber layer from The amount of protrusion L1 from the perpendicular line P is set as shown in Tables 1 and 2, respectively.

[0045] In addition, in the column of "the structure of the joint rubber layer" in Tables 1-2, when the joint rubber layer is the whole joint rubber layer, it is described as "whole", and when the joint rubber layer is the partial joint rubber layer, it is described as " "Partial".

[0046] For these 24 types of pneumatic tires, the following evaluation methods were used to evaluate the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com