pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire sidewalls, transportation and packaging, etc., can solve problems such as obstruction of air flow, poor durability, and easy to become cracks, to prevent vulcanization failures and improve crack resistance. performance, the effect of preventing local concentration of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

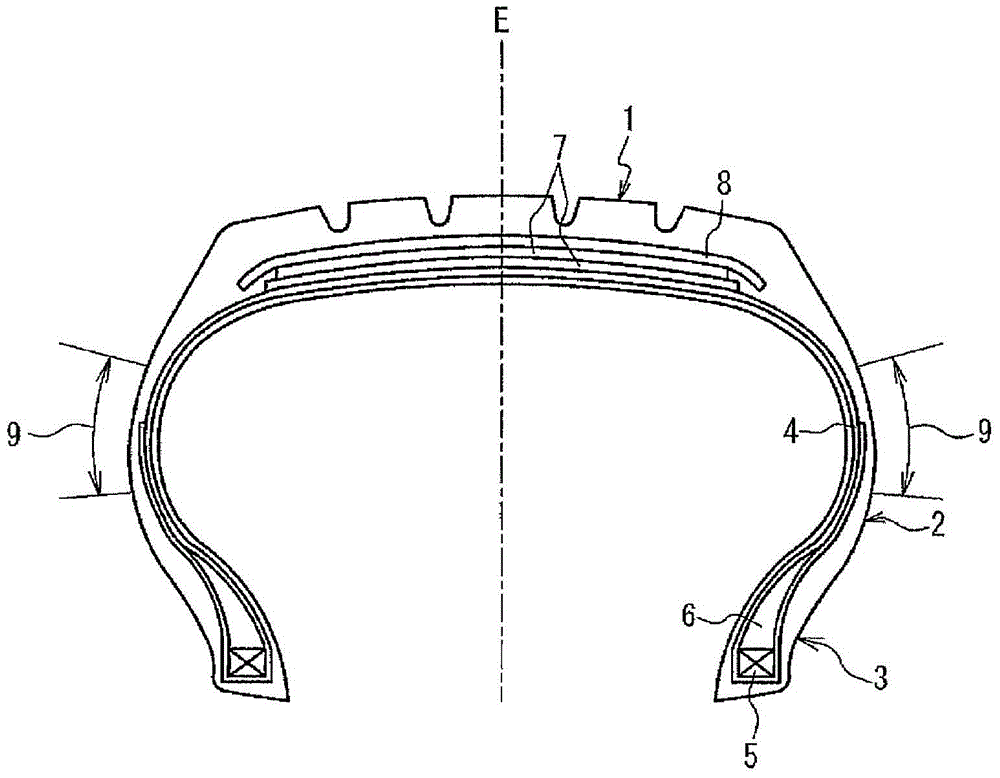

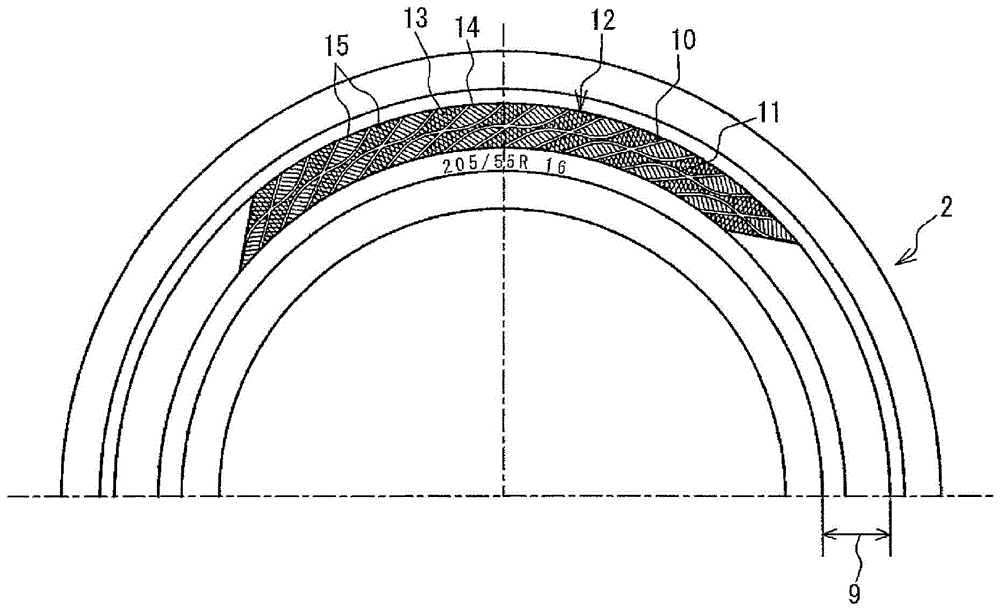

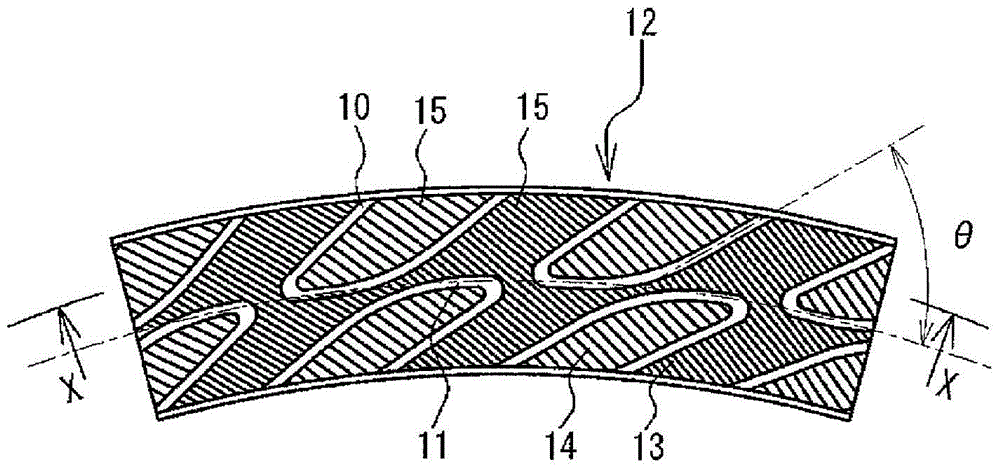

[0055] The tire size is 205 / 55R16, with figure 1 The cross-sectional shape shown, the decorative part structure provided on the side wall part, that is, the angle of the linear part of the radial and circumferential ribs, the shape of the circumferential rib, the width of the radial and circumferential ribs, The shape of the connecting portion, the respective shapes of the first region and the second region, the ratio of the total area, the ridge density, and the ratio of the ridge density of the first region to the second region are respectively shown in Table 1. Conventional example 1, comparison Examples 1 to 3 and Examples 1 to 8 total 12 kinds of pneumatic tires.

[0056] In addition, the ratio of the total area of each region refers to the ratio of the total area of each region to the area of the entire decorative part. The ratio of the ridge density refers to the ratio of the ridge density in the region with relatively large ridge density to the ridge density in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com