Pipe welding fixture

A pipe fitting welding and fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of scrapped workpieces, difficult to dissipate heat quickly, and leakage of weld bead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

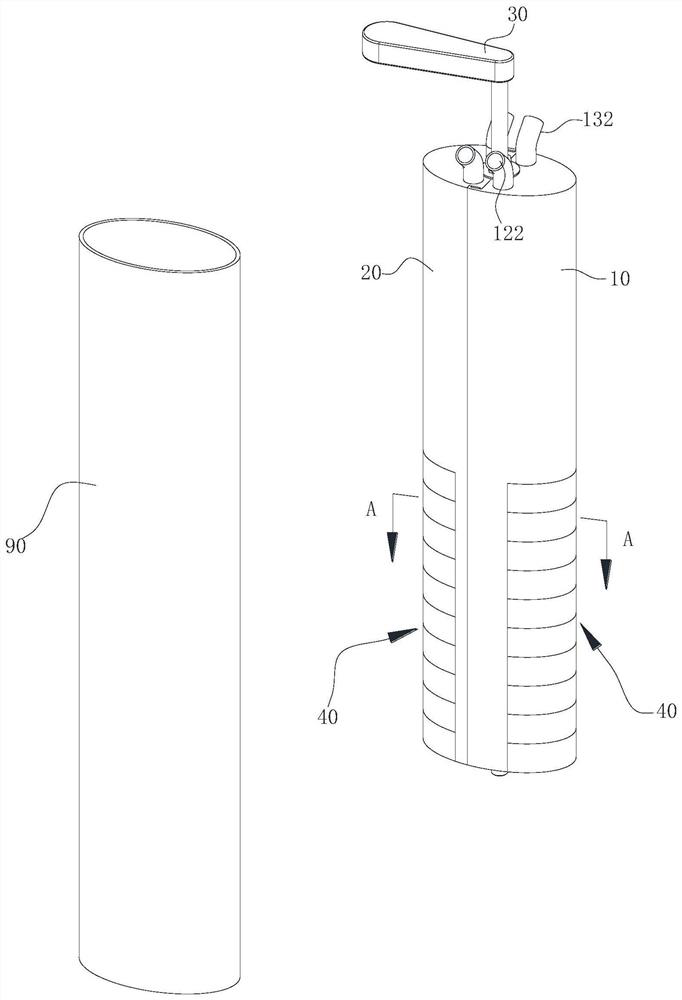

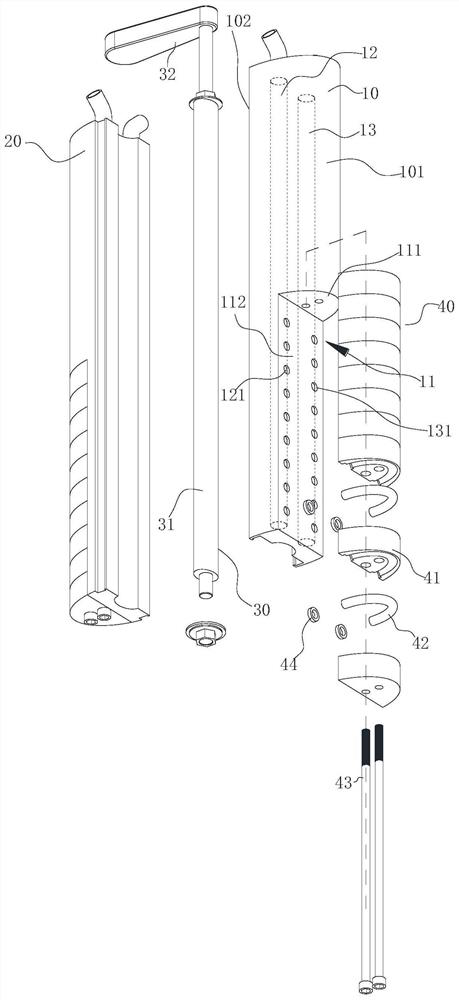

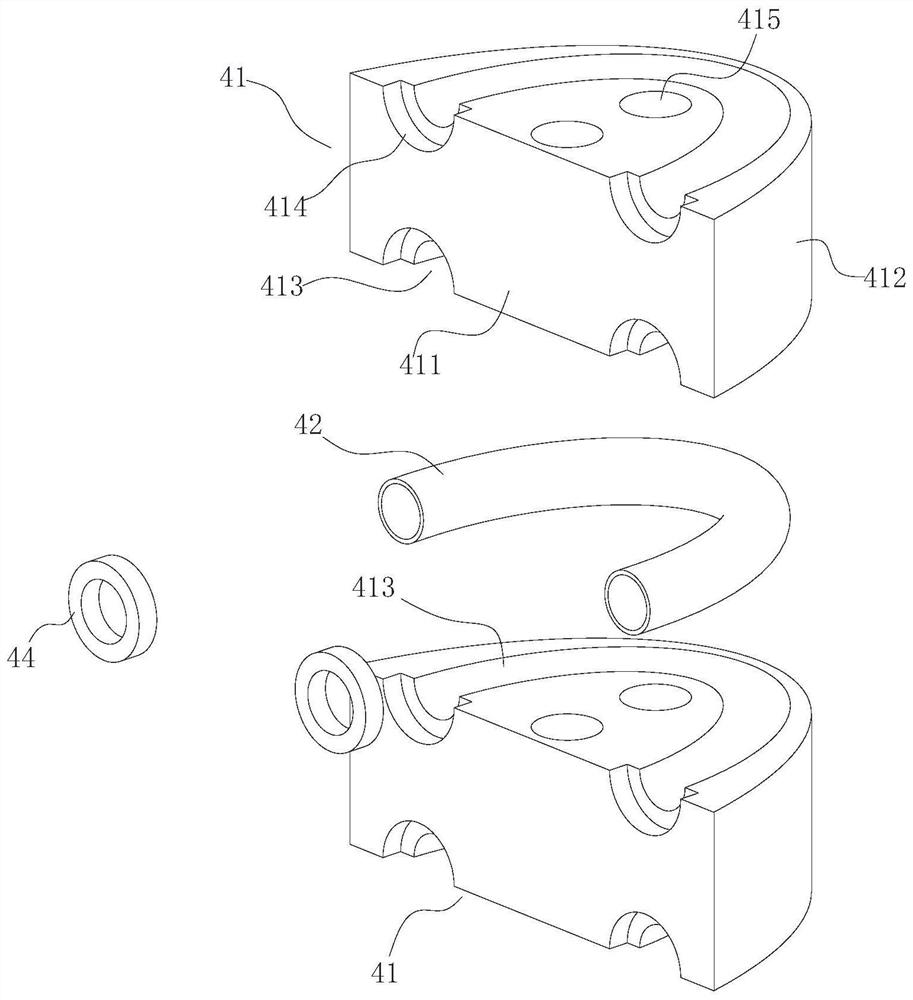

[0019] see figure 1 , 2 , 3, and 4 show a pipe fitting welding fixture of the present invention, which includes a mandrel 10, a mandrel 20, a spreader 30, and two heat-conducting members 40, wherein the mandrel 10 and the mandrel 20 are arranged oppositely and Inserted in the pipe 90, the spreader 30 is placed between the mandrel 10 and the mandrel 20, and the spreader 30 is used to push the mandrel 10 and the mandrel 20 toward the direction away from each other, so that the mandrel 10 The assembly with the mandrel 20 can be expanded to conform to the inner wall of the tube 90 . The structure of the mandrel 10 and the mandrel 20 is substantially the same, and the mandrel 10 is taken as an example below to illustrate its structure; the mandrel 10 includes a mating surface 102 on its inner side and a supporting surface 101 on its outer side, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com