Tertiary locking assembly for a thrust reverser

A technology of thrust reverser and locking components, which is applied in the direction of blade support components, electrical components, engine components, etc., which can solve the problems of less use and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

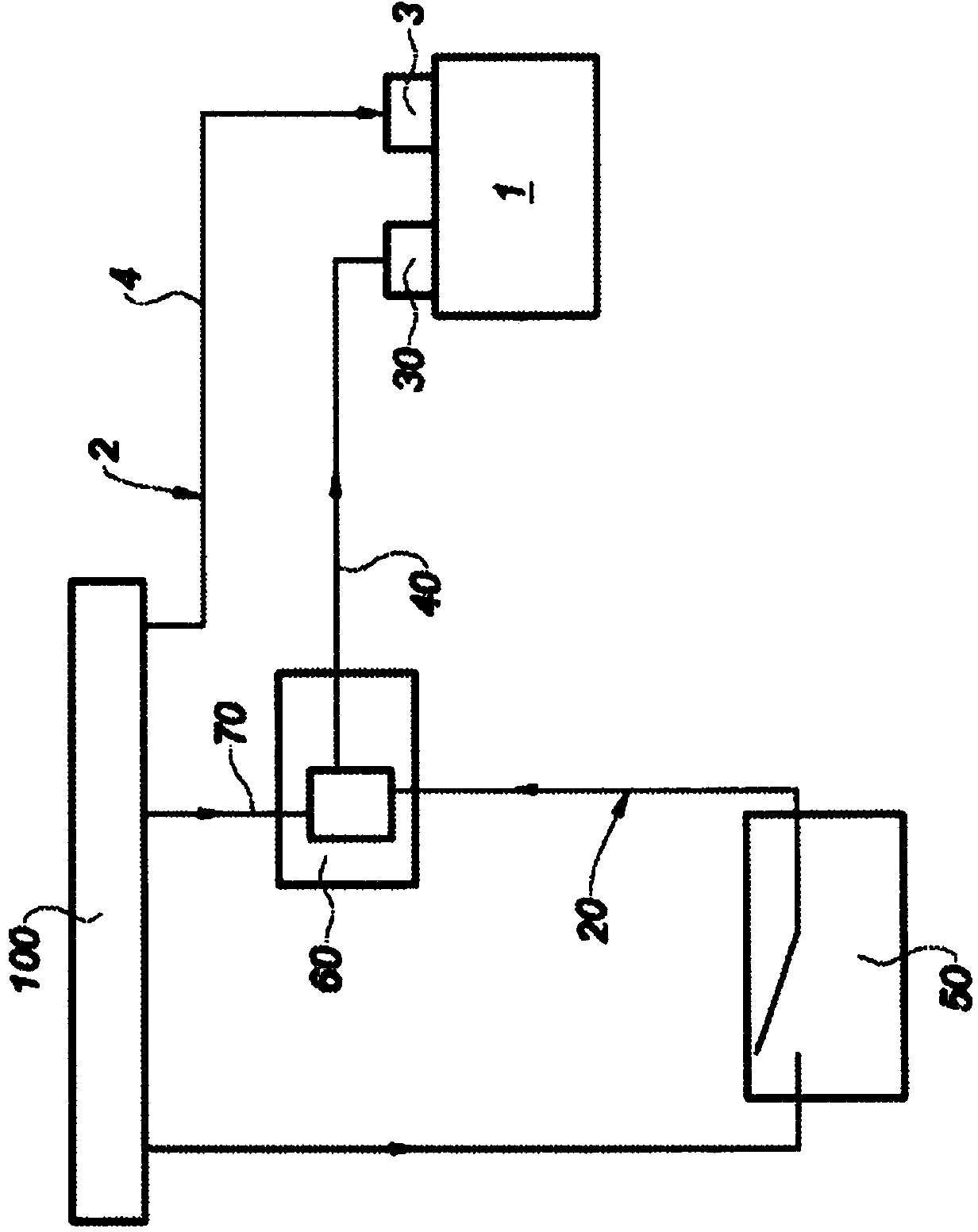

[0055] Such as figure 1 As shown in , the so-called third locking assembly of the thrust reverser comprises a third lock 1 associated with a primary control line 2 .

[0056] Said control circuit 2 comprises a solenoid 3 constituting the electromechanical control means of the third lock 1 . Of course, according to the type of the third lock 1, other electromechanical control devices are also applicable, and the present invention is not limited thereto.

[0057] This solenoid 3 is powered by a power supply line 4 from a junction box 100 between the turbojet engine nacelle and the pylon connected to it. The power supply line comes from the electrical grid of the aircraft.

[0058] In normal operation, during manipulation of the thrust reverser, commands from the aircraft activate the supply line 4 of the solenoid 3 so that it can drive the third lock 1 towards its withdrawn position, which then allows manipulation of the device as explained previously. At idle, the solenoid 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com