Plug connection for directly electrically contacting a circuit board

一种印刷电路板、连接部的技术,应用在接合/断开连接部件的装置、连接装置的零部件、电路等方向,能够解决影响压紧弹簧几何尺寸和插接力等问题,达到提高小型化程度、优化弹簧行程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

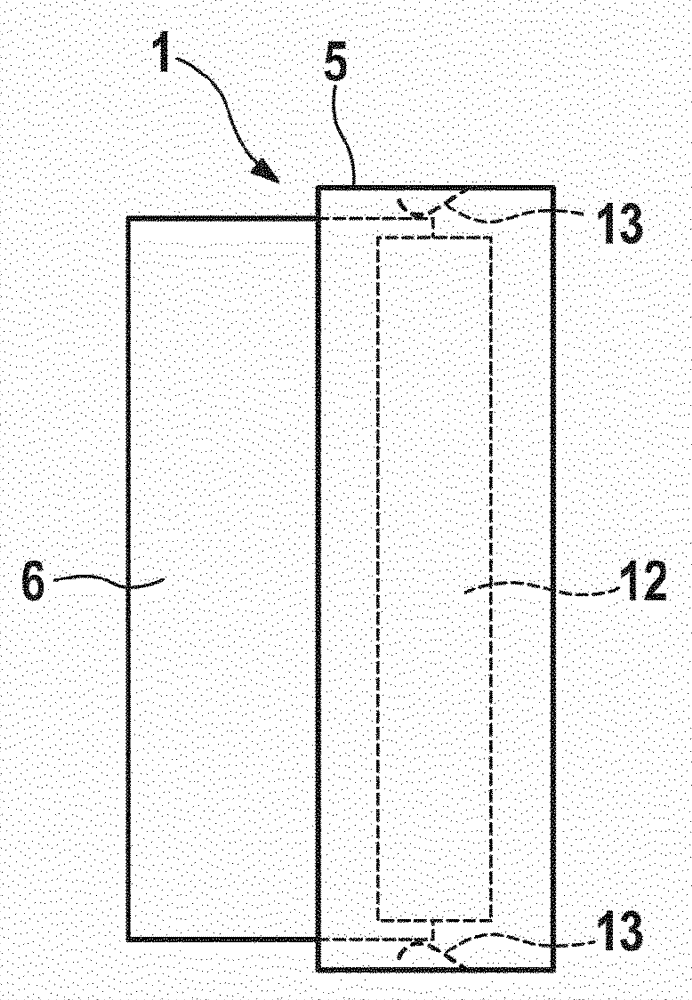

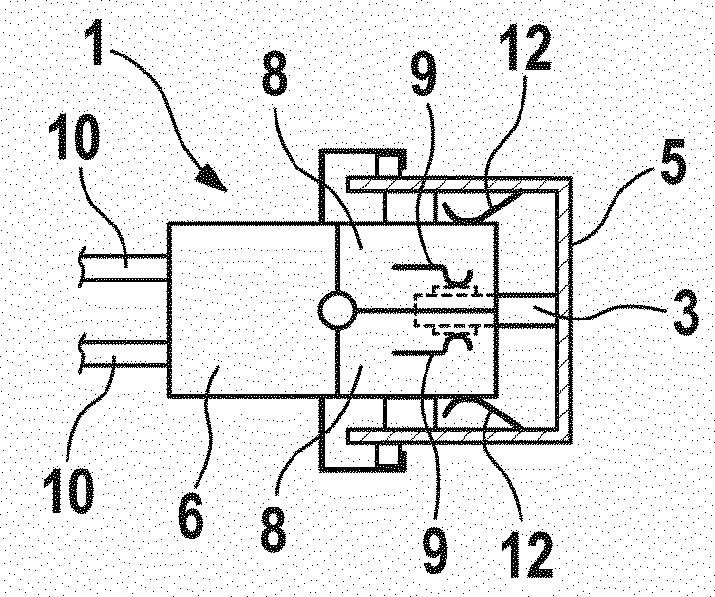

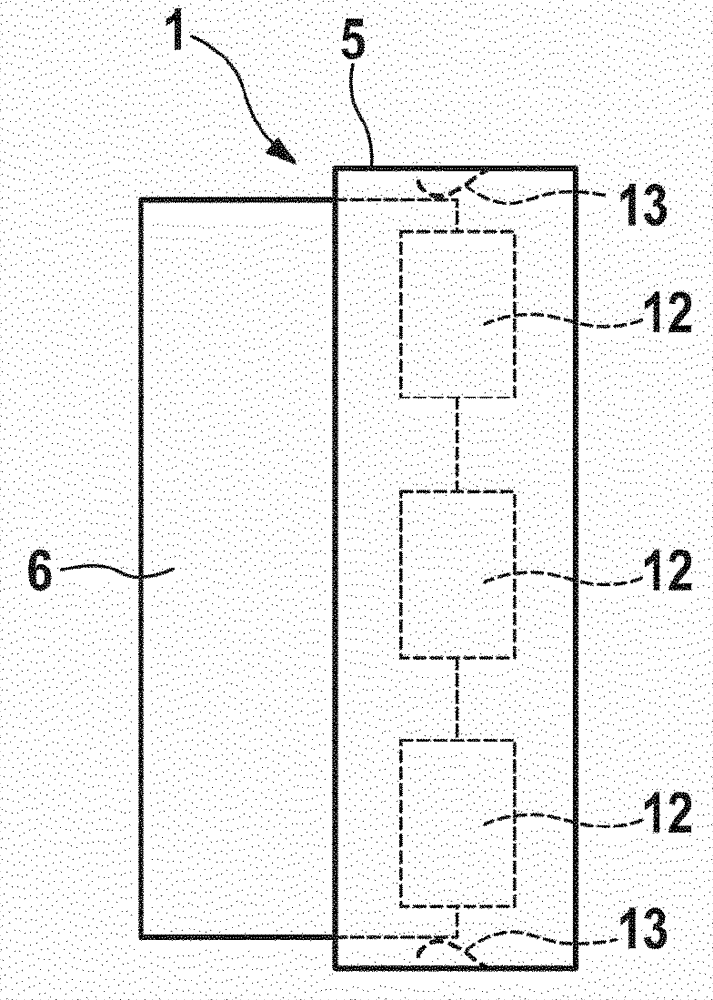

[0023] exist Figure 1a , 1b The plug connection 1 shown in is used for electrical direct contact on a printed circuit board 3 , also referred to as a "control device", with a contact surface ("bottom") 2, wherein the contact surface 2 can be arranged on the printed circuit board 3 Or it is arranged on both sides of the printed circuit board 3 .

[0024] A plug-in receptacle 5 that is open in the plug-in direction 4 and is provided with plug-in flanges or plug-in slots is provided on the printed circuit board 3 , in the region of its contact surface 2 , which is aligned with the plug-in direction. 4 protrudes oppositely into the plug receptacle. A plug (for example a cable harness plug) 6 is inserted into the plug receptacle 5 in the plug-in direction 4 and has two contact carrier halves 8 , which are hingedly connected to one another in 7 . as in Figure 1b As shown in , the printed circuit board 3 is inserted between the two contact carrier halves 8 , which in this case m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com