Mechanical agitation type magnetized fuel water doping device

A technology of mechanical stirring and fuel oil, which is applied in the direction of combustion method, liquid fuel supply/distribution, etc., can solve the problems of secondary pollution, ineffective fuel saving, uneven dispersion, etc. The effect of high degree of chemicalization and uniform mixing of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

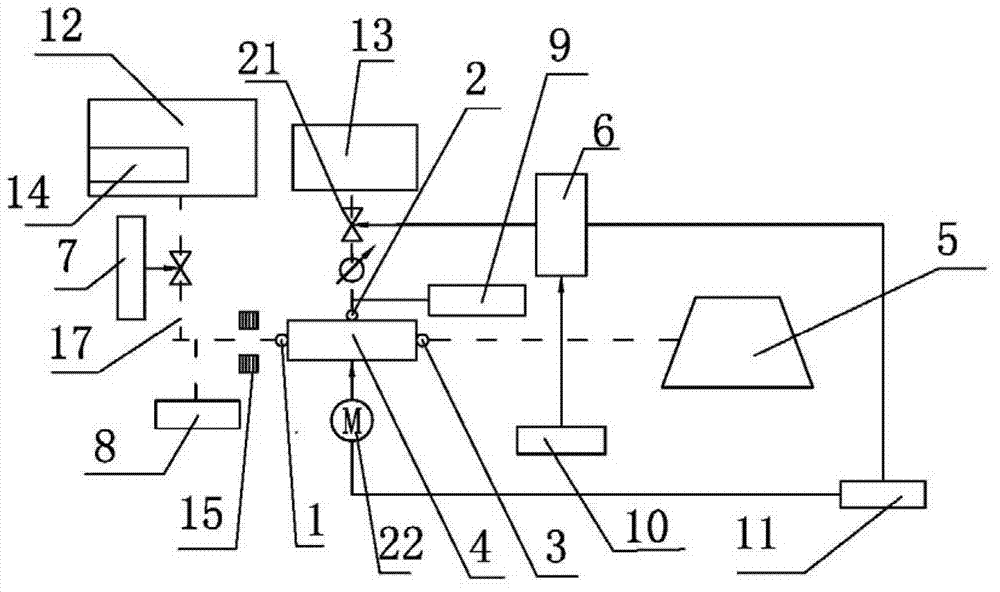

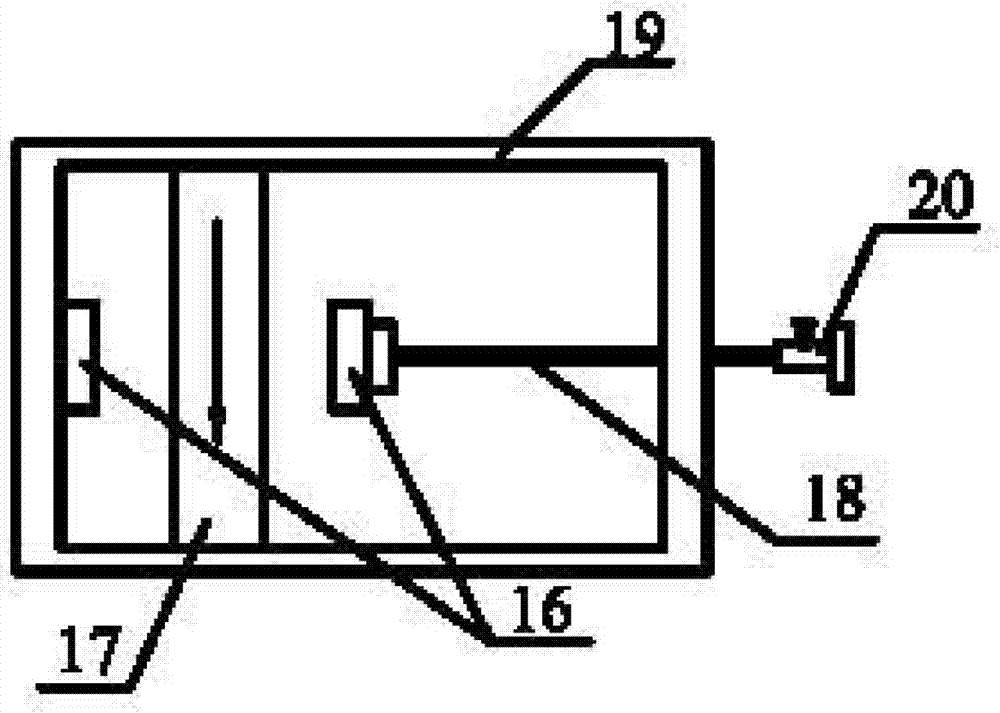

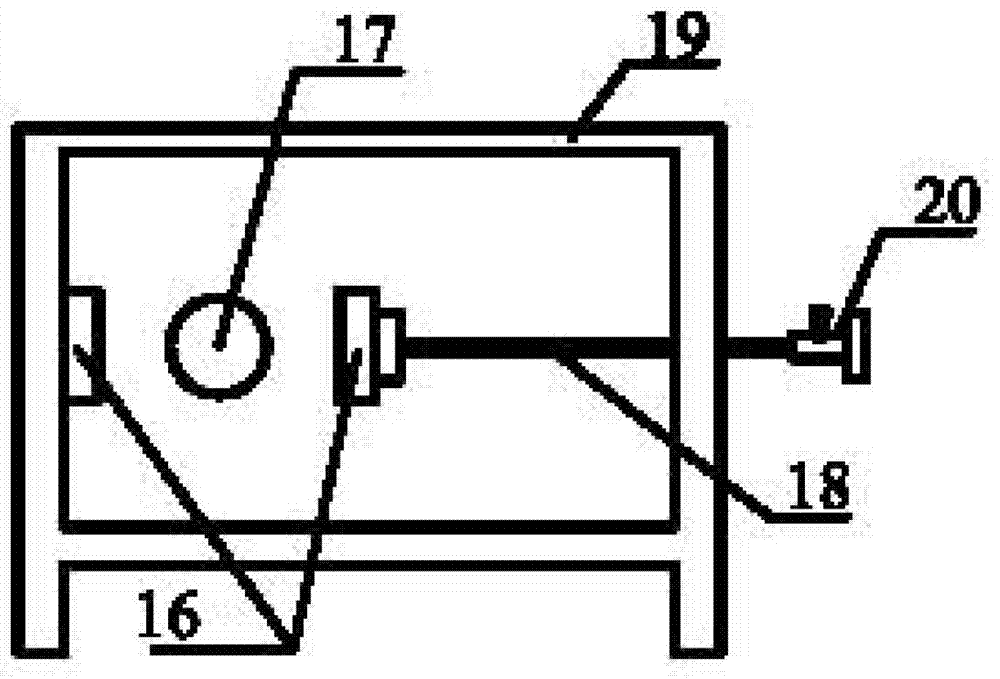

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] like Figure 1-3 As shown, a mechanical stirring type magnetized fuel water mixing device includes an emulsifier 4, a magnetization treatment device 15, a water-mixed fuel tank 5 and a monitoring system; the emulsifier 4 has three quick interfaces, which are respectively water-mixed fuel outlets 3. Water inlet 2 and fuel inlet 1; the monitoring system includes PLC6, PLC analog input module, PLC analog output module, water metering pump 9, fuel metering pump 8, stirring motor 22, thermometer 10, liquid level gauge, Solenoid valve A7 and motor frequency converter 11;

[0036] The fuel inlet 1 is respectively connected to the fuel tank 12 and the fuel metering pump 8 through the fuel pipeline 17 through the magnetization treatment device 15, and the fuel pipeline 17 between the fuel tank 12 and the emulsifier 4 is equipped with a solenoid valve A7; A heater 14 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com