Method for preparing starch-base soft capsules based on co-blending extrusion method

A technology of starch and capsules, which is applied in the fields of capsule delivery, pharmaceutical formula, food forming, etc. It can solve problems such as uneven mixing and lax capsule inclusion, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

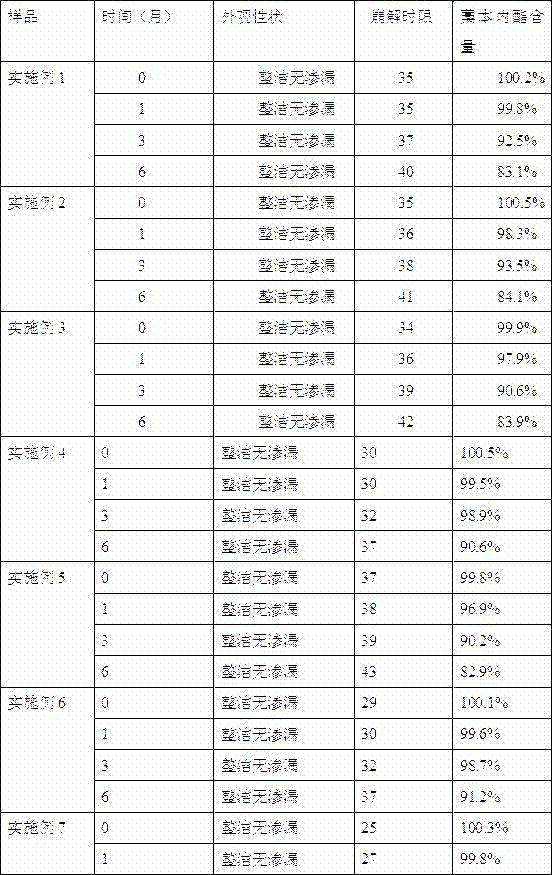

Examples

Embodiment 1

[0039] The raw materials used and the weight ratio are as follows:

[0040] Gel agent: carrageenan, 2%;

[0041] Starch: corn starch, 75%;

[0042] Moisture retention agent: pharmaceutical grade glycerin, 1%;

[0043] Anticaking agent: pharmaceutical grade stearic acid, 0.2%;

[0044] Emulsifier: pharmaceutical grade sodium lauryl sulfate, 0.02%;

[0045] Paste agent: deionized water, 21.78%.

[0046] The parameters of the twin-screw extruder are as follows:

[0047] The rotating speed of screw rod is 350 rev / mins, and wherein the temperature that each slide block is set is:

[0048] Slider 1: 25°C

[0049] Slider 2-3: 110°C

[0050] Sliders 4-6: 145°C

[0051] Sliders 7-9: 165°C

[0052] Slider 10-12: 160°C

[0053] Nozzle: 160°C

[0054] The parameters of the single screw extruder are as follows:

[0055] Extrude under the condition that the rotation speed of the screw is 300 rpm, and the temperature set by each slider is 120°C.

[0056] The preparation steps of...

Embodiment 2

[0058] The raw materials used and the weight ratio are as follows:

[0059] Gel agent: xanthan gum, 2%;

[0060] Starch: corn starch, 75%;

[0061] Moisture retention agent: pharmaceutical grade glycerin, 3%;

[0062] Anticaking agent: pharmaceutical grade stearic acid, 0.2%;

[0063] Emulsifier: pharmaceutical grade sodium lauryl sulfate, 0.02%;

[0064] Pasting agent: deionized water, 19.78%;

[0065] All the other are with embodiment 1.

Embodiment 3

[0067] The raw materials used and the weight ratio are as follows:

[0068] Gel agent: guar gum, 2%;

[0069] Starch: tapioca starch, 75%;

[0070] Moisture retention agent: pharmaceutical grade glycerin, 1%;

[0071] Anticaking agent: pharmaceutical grade stearic acid, 0.5%;

[0072] Emulsifier: pharmaceutical grade sodium lauryl sulfate, 0.02%;

[0073] Pasting agent: deionized water, 21.48%;

[0074] All the other are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap