High-precision dispensing valve for COB

A dispensing valve, high-precision technology, used in coatings, devices that apply liquid to the surface, etc., can solve the problems of small amount of glue in the dispensing valve, inconvenient disassembly and cleaning, and unsatisfactory exhaust performance. , to achieve the effect of convenient and fast on-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

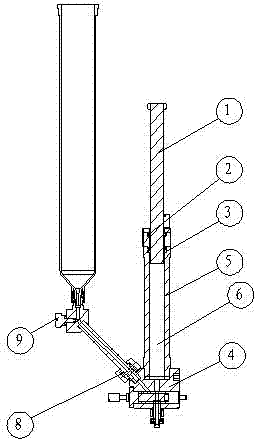

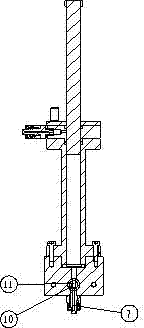

[0015] like figure 1 , figure 2 As shown, the present invention includes a valve seat 4, a pump body 5 and a connecting portion affixed to the outer surface of the valve seat. The pump body is provided with a slideway 6 communicating with the valve seat, and the slideway is adapted to slide with the slideway. The matching injection rod 1, the bottom of the valve seat is connected with the drain joint 7, and the valve seat is provided with a valve core assembly that can control the valve seat and the drain joint. There is an open liquid inlet passage 8, and the end of the liquid inlet passage away from the valve seat is provided with a vent hole, and a vent screw 9 is fitted on the vent hole.

[0016] The injection rod can be driven by a stepping motor to realize high-precision glue spit, and is inserted into the slideway from top to bottom, and the head of the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com