Grade screening machine for fritillaria ussuriensis maxim

A screening machine, flat fritillary technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of short residence time, scratches, long conveying distance, etc., and achieve the effect of avoiding the chance of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

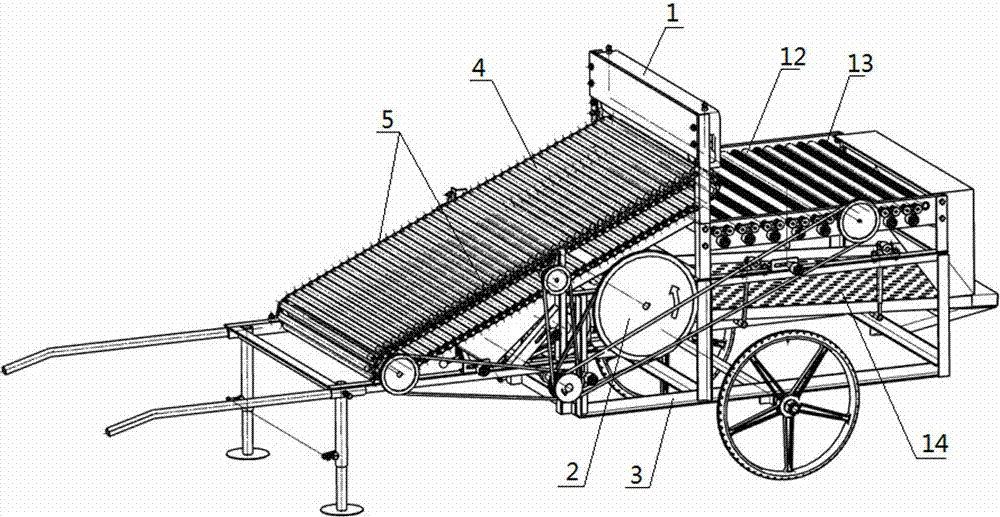

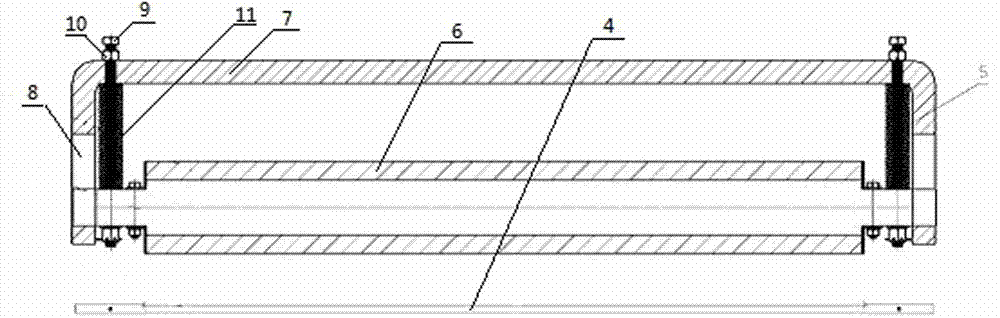

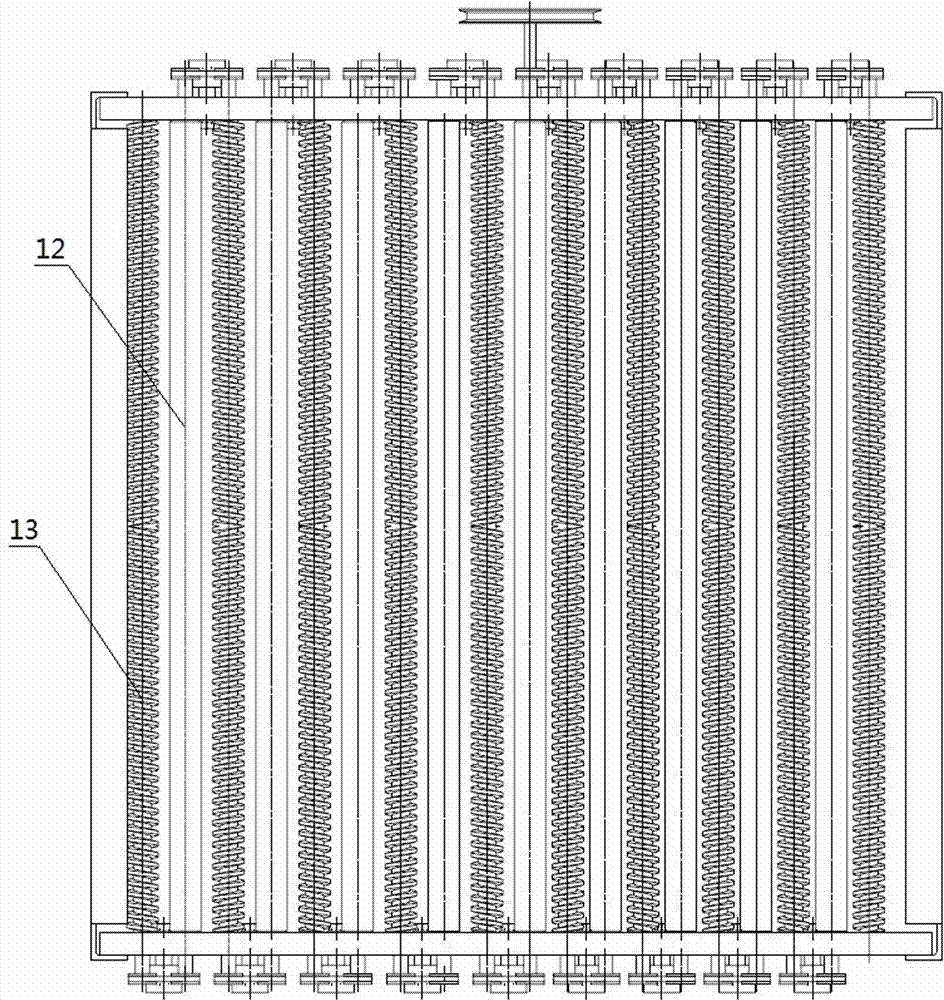

[0016] Examples of the present invention Figures 1 to 3 As shown, the flat fritillaria grade screening machine can be used for flat fritillary particle screening, which is equipped with a conveying separation unit, a feeding unit 1, a spiral curve screening unit, a flat screen unit, a power unit 2 and a frame 3; Unit 2 is composed of an oil extraction machine or a gasoline engine and a transmission mechanism. The conveying and separating unit is provided with a number of circularly arranged parallel conveying rods 4. The conveying rods 4 can be columnar or sheet-shaped, and the gap between adjacent conveying rods is 6 to 8mm. The two ends of each conveying rod are respectively connected on two endless chains 5, and the two endless chains 5 are respectively supported by a driving gear and a driven gear to form a conveying mechanism, and the driving gear and the driven gear are connected on the frame through a shaft, and the driving gear and the driven gear The connecting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com