Skin stretch-forming method with transition sectional face of flexible multipoint mould

A technology of multi-point mold and mold surface, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of a large number of molds, achieve high processing accuracy, save manufacturing costs, and achieve considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

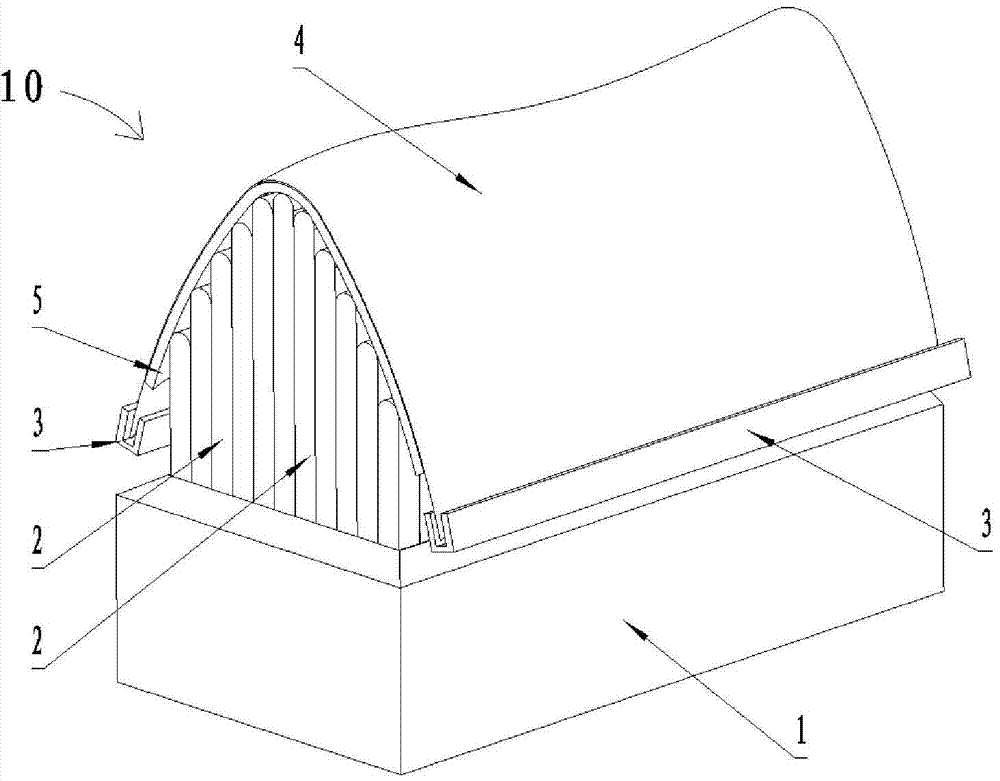

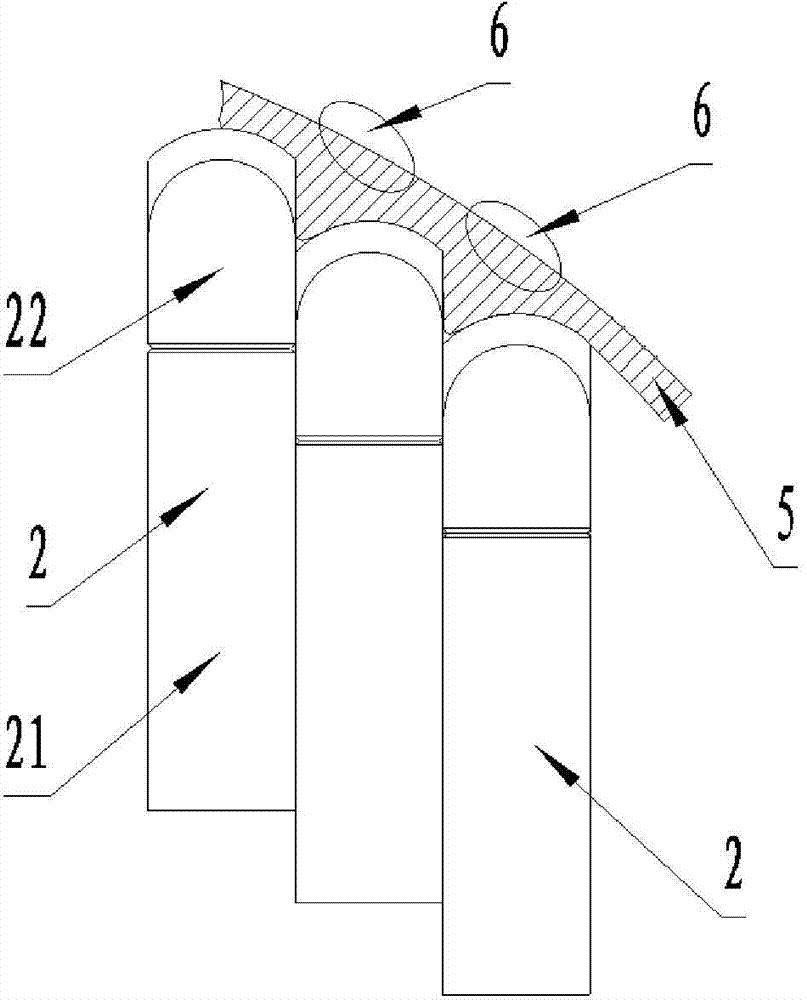

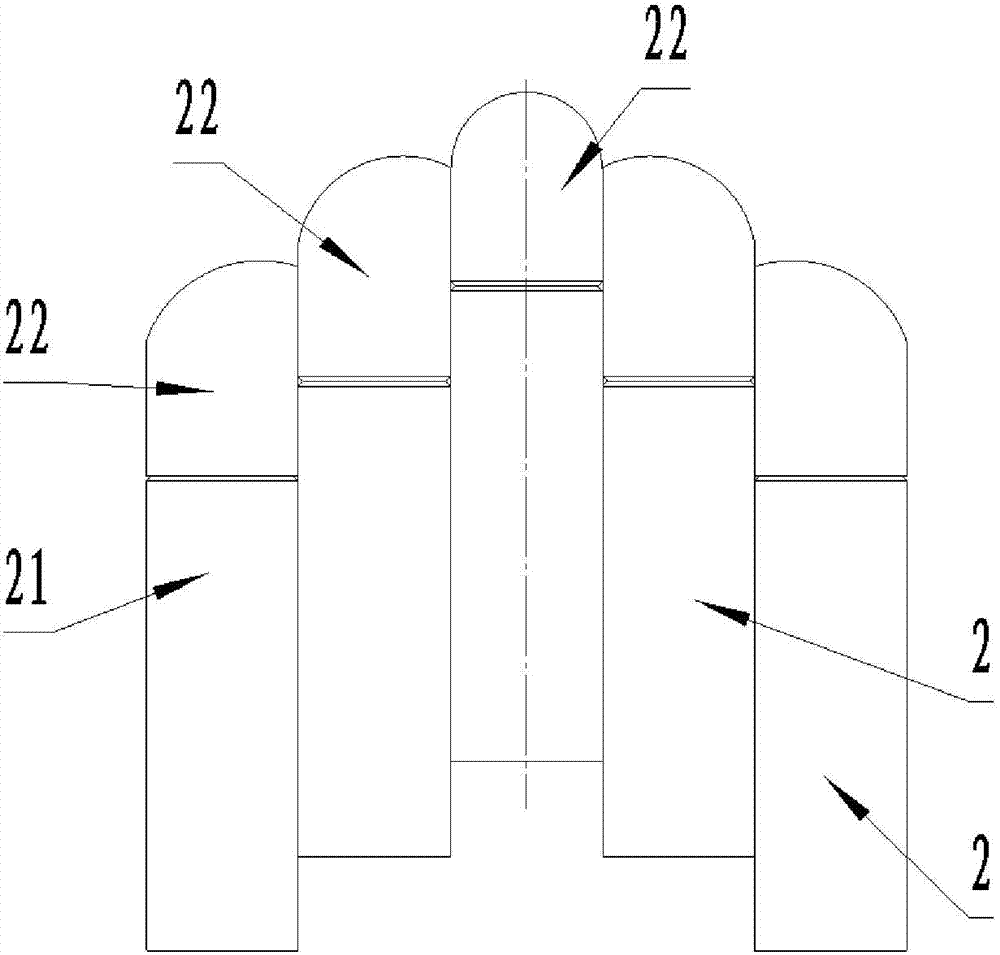

[0029] The skin pulling device for the transitional surface of the flexible multi-point mold according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A skin-drawing device 10 for a flexible multi-point mold transition profile, including a mold base 1, which contains a plurality of punches 2, and the height of the top of each punch 2 can be adjusted independently. The flexible The skin stretching device for the transitional surface of the multi-point mold also includes clamps 3 for clamping and stretching the skin 4, such as figure 1 shown.

[0030] A large number of discrete height-adjustable punches are distributed in a row to fit the three-dimensional surface of the mold, so that the forming requirements of parts with different shapes can be met and multiple solid molds can be replaced. In addition, the top of the punch generates multiple transitional profiles, thereby realizing multi-pass drawing, making th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com