Low-temperature-rise type screw for rubber extrusion filter

A filter and screw technology, which is applied in the field of low temperature rise screw of rubber extrusion filter, can solve the problems of reducing heat generation and temperature rise of extruded rubber, and achieves the effect of reducing heat generation and solving excessive temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

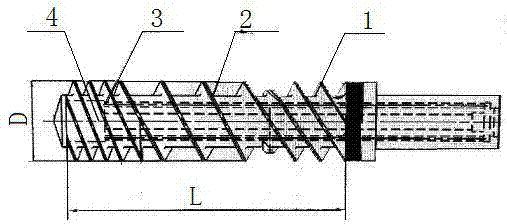

[0010] Such as figure 1 As shown, the low-temperature rising screw of the rubber extrusion filter is composed of a screw feeding section 1 with 4 threads, a conveying section 2 with 2 threads, and a quantitative section 3 with 4 threads. There is a cooling water channel 4 in the center of the screw. 4. Water is fed into a single hole in the center of the screw, and water is returned in multiple holes around the screw. The length-to-diameter ratio of the screw is 1:3.5. This invention changes the thread structure of the conventional screw, changes the number of threads in the feeding section of the screw, and cuts the wide film into narrow strips. In order to reduce the temperature of the rubber material, the length-to-diameter ratio of the screw is changed, the length of the screw thread in the conveying section is shortened, the heat generated by the conveying distance is reduced, and the number of thread heads in the quantitative section is increased, and the large rubber mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com