Powder conveying mechanism

A technology of conveying mechanism and powder, applied in the direction of conveyor, transportation and packaging, can solve the problems of inability to realize quantitative conveying, low conveying efficiency of conveyor belt, different amount of powder, etc., to facilitate adjustment, improve conveying efficiency, The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

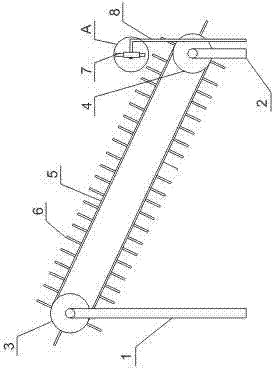

[0024] Such as figure 1 As shown, the powder conveying mechanism includes a fixed rod A1, a fixed rod B2, a roller A3, a roller B4, a conveyor belt 5, a baffle 6 and a scraper 7, and the roller A3 and the roller B4 are respectively fixed by the fixed rod A1 and the fixed rod B2. The conveyor belt 5 is set on the roller A3 and the roller B4, the roller B4 is located obliquely below the roller A3, a plurality of baffles 6 are evenly distributed on the conveyor belt 5, and the scraper 7 is arranged above the roller B4.

Embodiment 2

[0026] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a fixing frame 8 through which the scraper 7 is fixed above the roller B4.

Embodiment 3

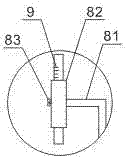

[0028] Such as figure 2 As shown, this embodiment is based on Embodiment 2, the fixed frame 8 includes a support rod 81, a rectangular cylinder 82 and a bolt 83, the rectangular cylinder 82 is fixed on the support rod 81, and the scraper 7 is slidably arranged on a rectangular In the barrel 82 , bolts 83 penetrate the rectangular barrel 82 to compress the scraper 7 in the rectangular barrel 82 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com