Method for manufacturing solid block by using sludge, solid block, and backfilling method

A solid block and sludge technology, applied in the field of solid blocks, can solve problems such as pollution, occupation of land resources, carcinogenic air, etc., and achieve the effect of avoiding environmental pollution and sludge damage to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

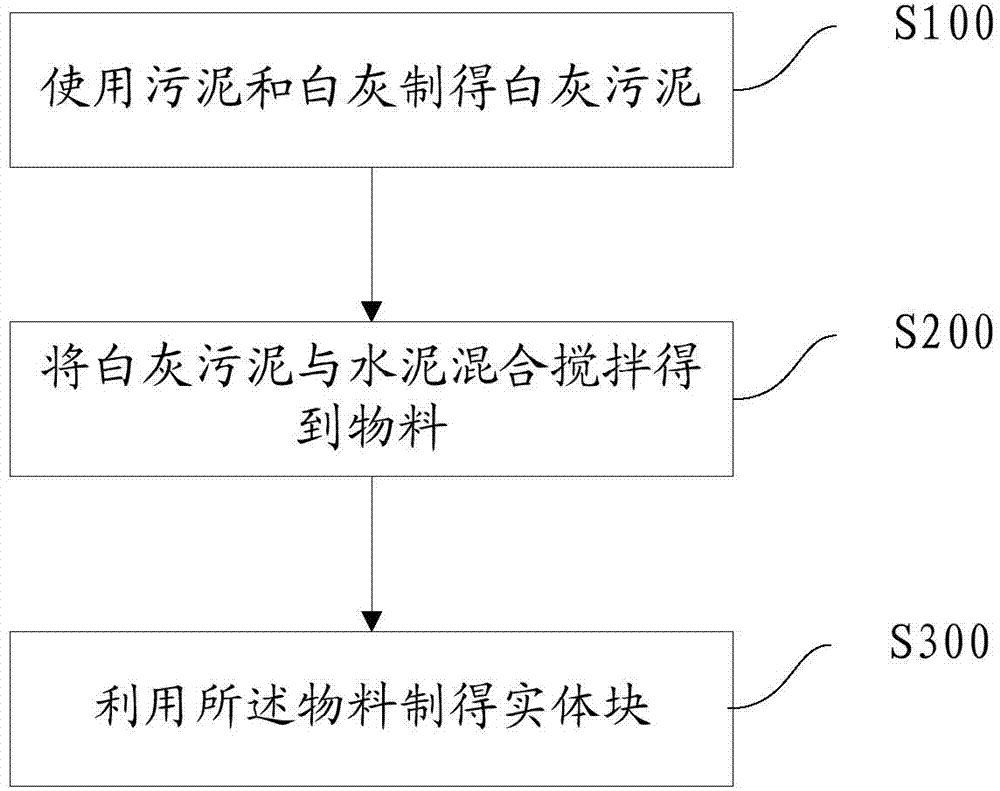

[0031] figure 1 It is a flow chart of the method for producing solid blocks from sludge in the present invention. The method for manufacturing a solid block from sludge disclosed in the present invention includes the following steps S100, S200 and S300.

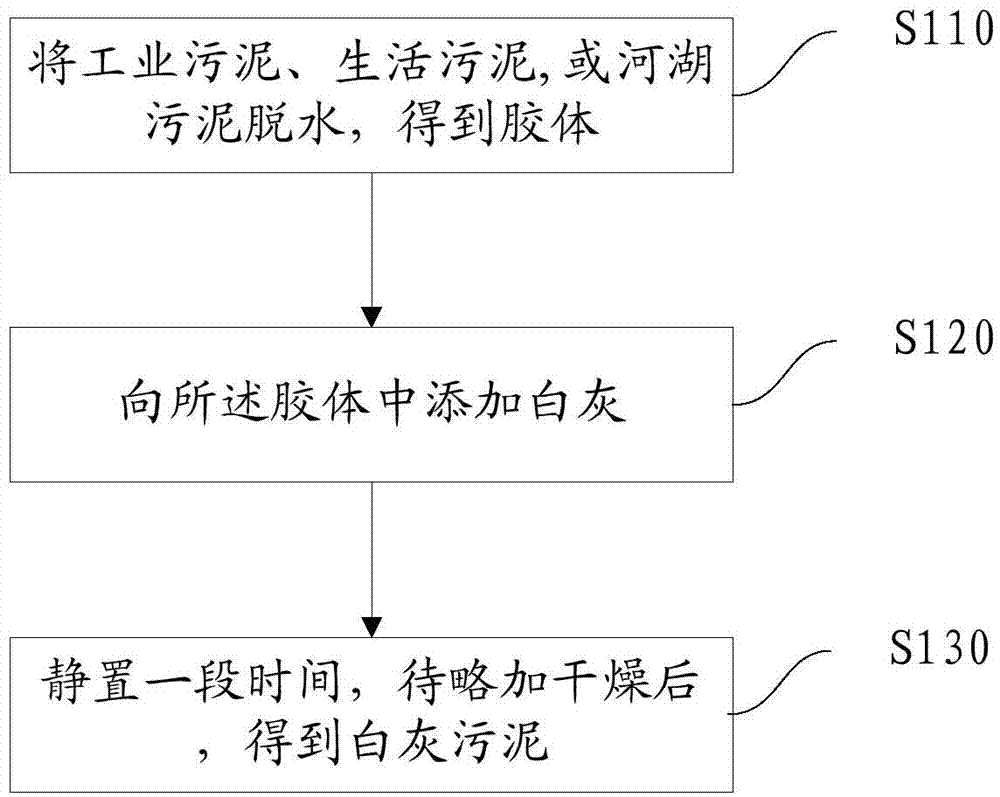

[0032] S100, preparing lime sludge by using sludge and lime. Among them, lime sludge is also called dried sludge.

[0033] S200, mixing lime sludge and cement to obtain materials. Wherein, the present invention uses a mixer or a mixer to fully mix the lime sludge and cement obtained through step S100 to obtain materials. In the present invention, the ratio of the mass of cement to the mass of lime sludge is 2%-7%, preferably, the ratio of the mass of cement to the mass of lime sludge is 3%-5%. By adding cement, the compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com