Electric double hand rubbing bionic device

A two-handed, electric technology, applied in electromechanical devices, transmission devices, electric components, etc., can solve the problems of high cost, complex structure, high cost, etc., and achieve the effects of wide popularization, high work reliability and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

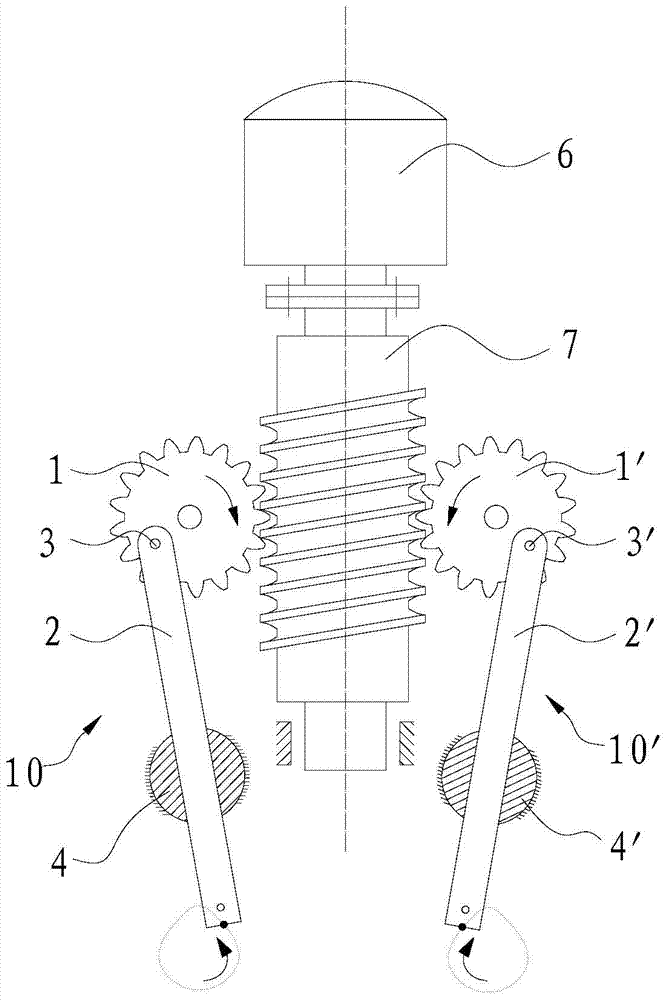

[0028] see figure 1 The shown bionic device for electric hands rubbing includes a frame (not shown in the figure), and two sets of rubbing components 10, 10' arranged on the frame.

[0029] The kneading assembly 10 includes a worm wheel 1 that is rotatably arranged on the frame around the axis, a connecting rod 2 that is rotatably arranged on the worm wheel 1 through a pin shaft 3, and is hinged on the frame and can rotate around its own axis. Cylinder 4. There is an eccentric pin hole on the worm wheel 1, the center line of the pin hole is parallel to the axis line of the worm wheel 1, one end of the pin shaft 3 is connected to the upper part of the connecting rod 2, and the other end is rotatably passed through the above pin hole middle.

[0030] The axis line of the cylinder 4 is parallel to the axis line of the worm wheel 1, and the cylinder 4 is provided with a radially through-hole, and the connecting rod 2 is fitted in the above-mentioned through hole with clear...

Embodiment 2

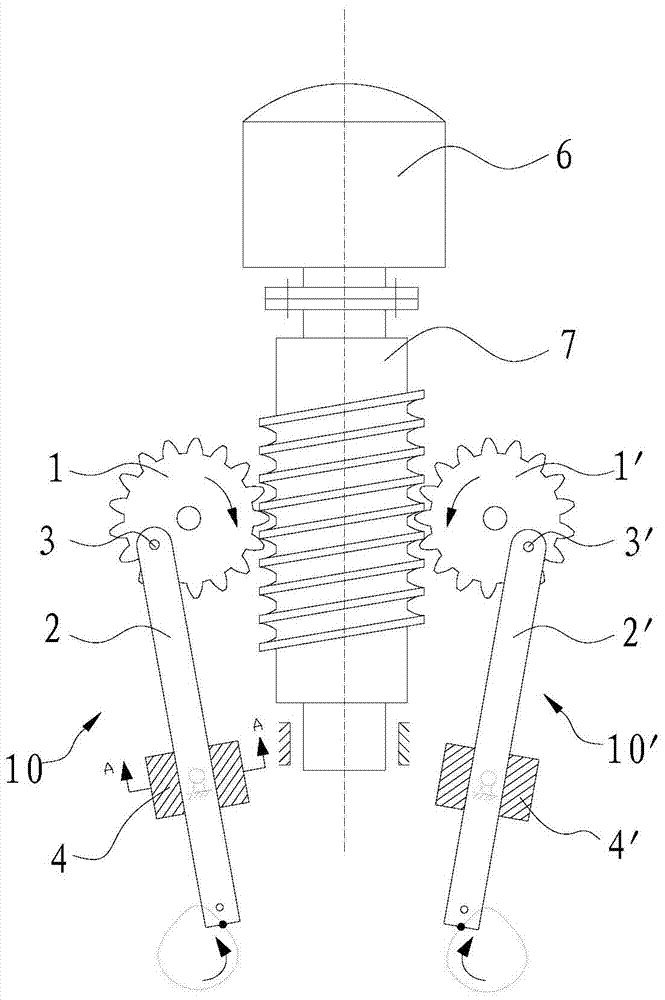

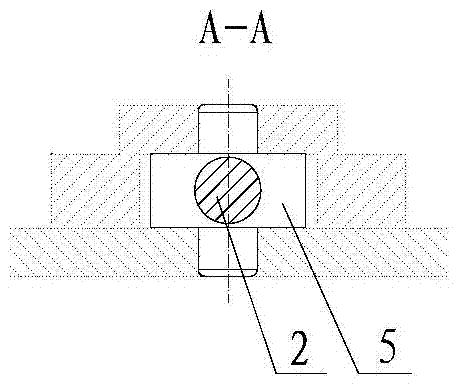

[0035] see figure 2 Shown electric hands rubbing bionic device, the difference between this bionic device and embodiment 1 mainly lies in the setting of the parts that provide connecting rod 2, 2' guide. In this embodiment, the connecting rod 2, 2' is provided as the center of the sliding seat 5, 5' hinged on the frame, and the two axial ends of the sliding seat 5, 5' are at the hinge point on the frame. The connecting line is parallel to the axes of the gears 1 and 1'. The sliding seats 5, 5' are respectively provided with through holes for the connecting rods 2, 2' to penetrate, and the connecting rods 2, 2' are respectively fitted in the through holes on the sliding seats 5, 5' with clearance fit, and the connecting rods 2, 2' and sliding seat 5, 5' respectively form a plane low pair, when the worm 7 rotates to drive the worm gear 1, worm gear 1' to rotate, the connecting rods 2, 2' are opposite to each other under the action of the pin shaft 3, 3' respectively Since t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap