A single led light module

A technology for optical components and light-emitting components, which is applied to semiconductor devices, light sources, and electric light sources of light-emitting components to achieve high thermal conductivity, good thermal conductivity, and reduced thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

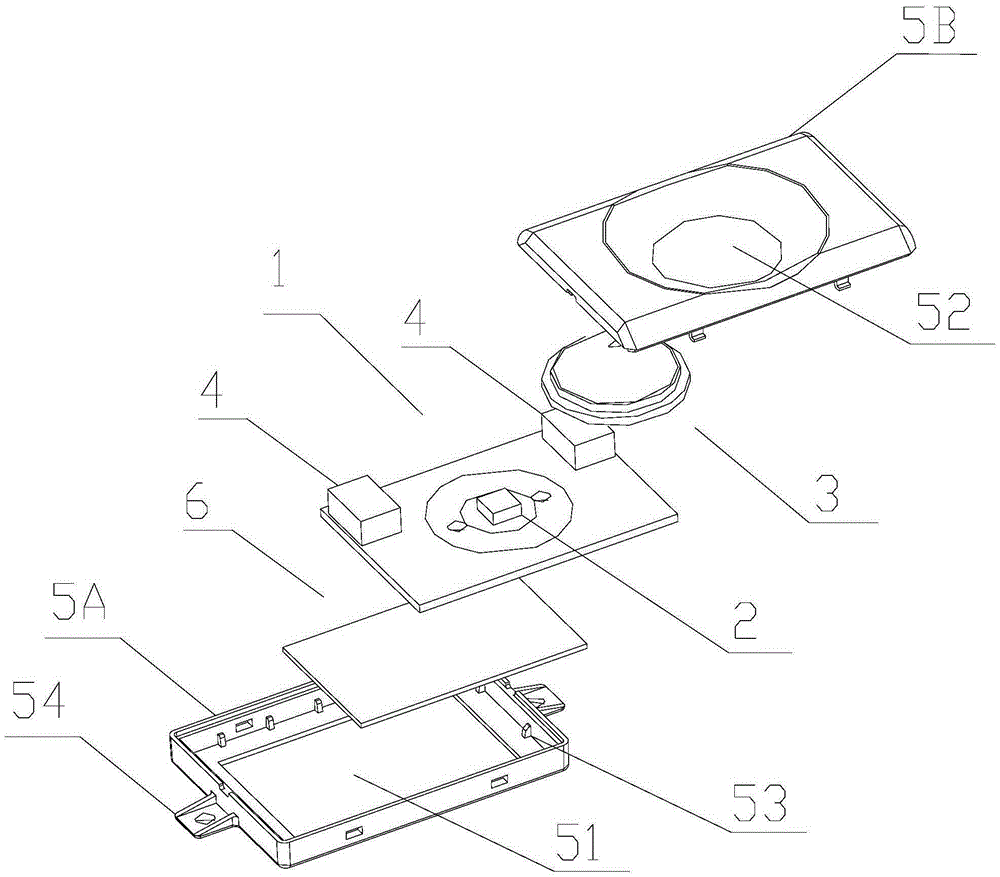

[0026] Such as figure 1 As shown, a single LED light component includes an insulating box body and a light-emitting component; the box body is composed of a base 5A and an upper cover 5B matched with the base 5A, and the cavity formed by the base 5A and the upper cover 5B accommodates the light-emitting component; The base 5A is a surrounding frame structure with a hole 51 on the bottom surface; the upper cover 5B is provided with a through hole 52 .

[0027] Since the base 5A of the box body is a surrounding frame structure with a hole 51 dug out for the bottom surface, the LED light component monomer can conduct heat through the hole 51, avoiding the accumulation of heat in each monomer, and solving the problem of Solved the heat dissipation problem of the single LED light component. The insulating material can be resin, organic polymer material, ceramics and other materials. In order to electrically insulate the light-emitting component inside the box body from the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com