8-shaped rib processing machine

A processing machine and processing unit technology, applied in the field of processing machines and tools, can solve the problems of reducing arch clearance, non-uniform size, complex structure, etc., to improve processing accuracy and size uniformity, reduce the number of bending times, and the process is simple and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

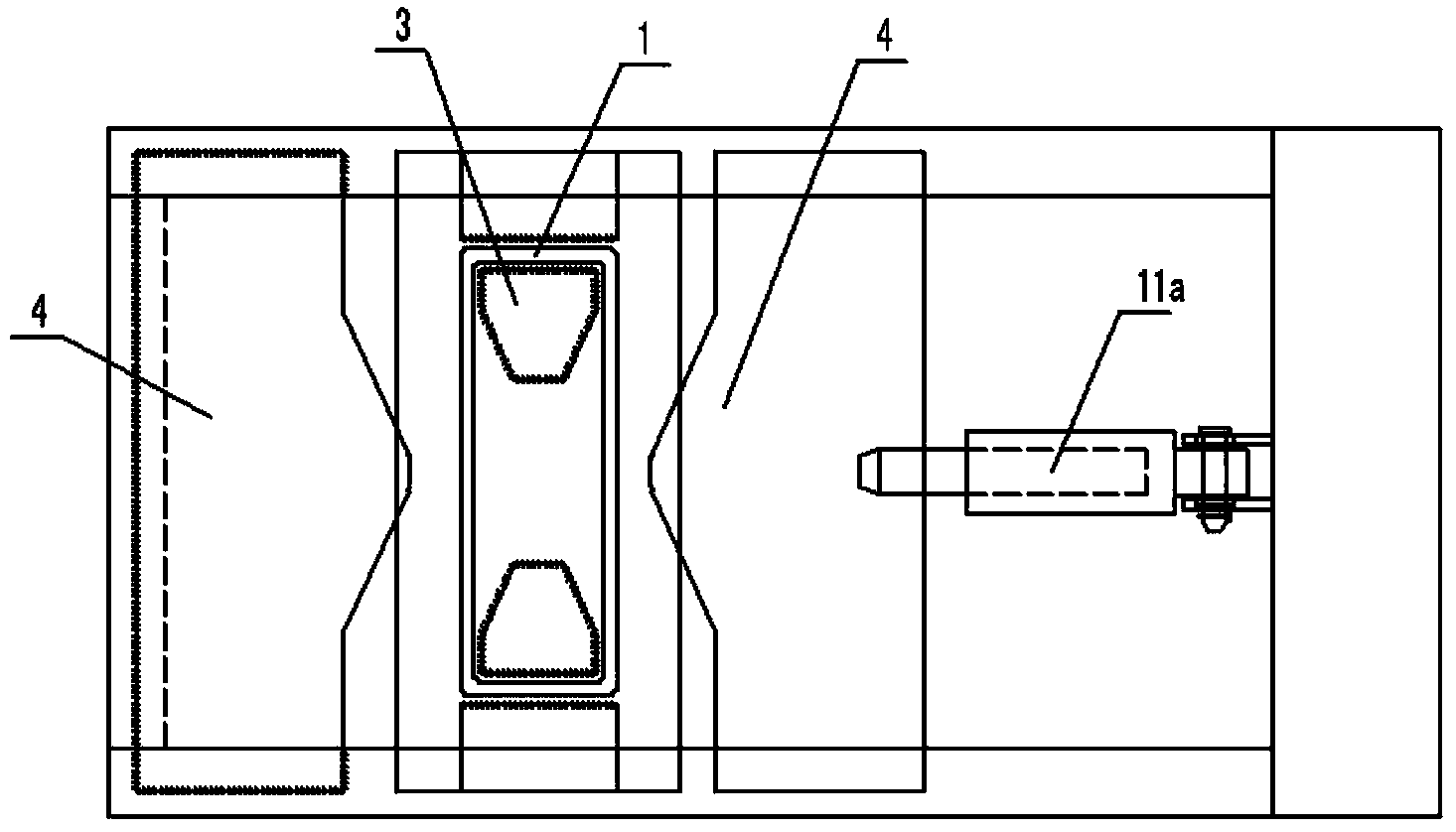

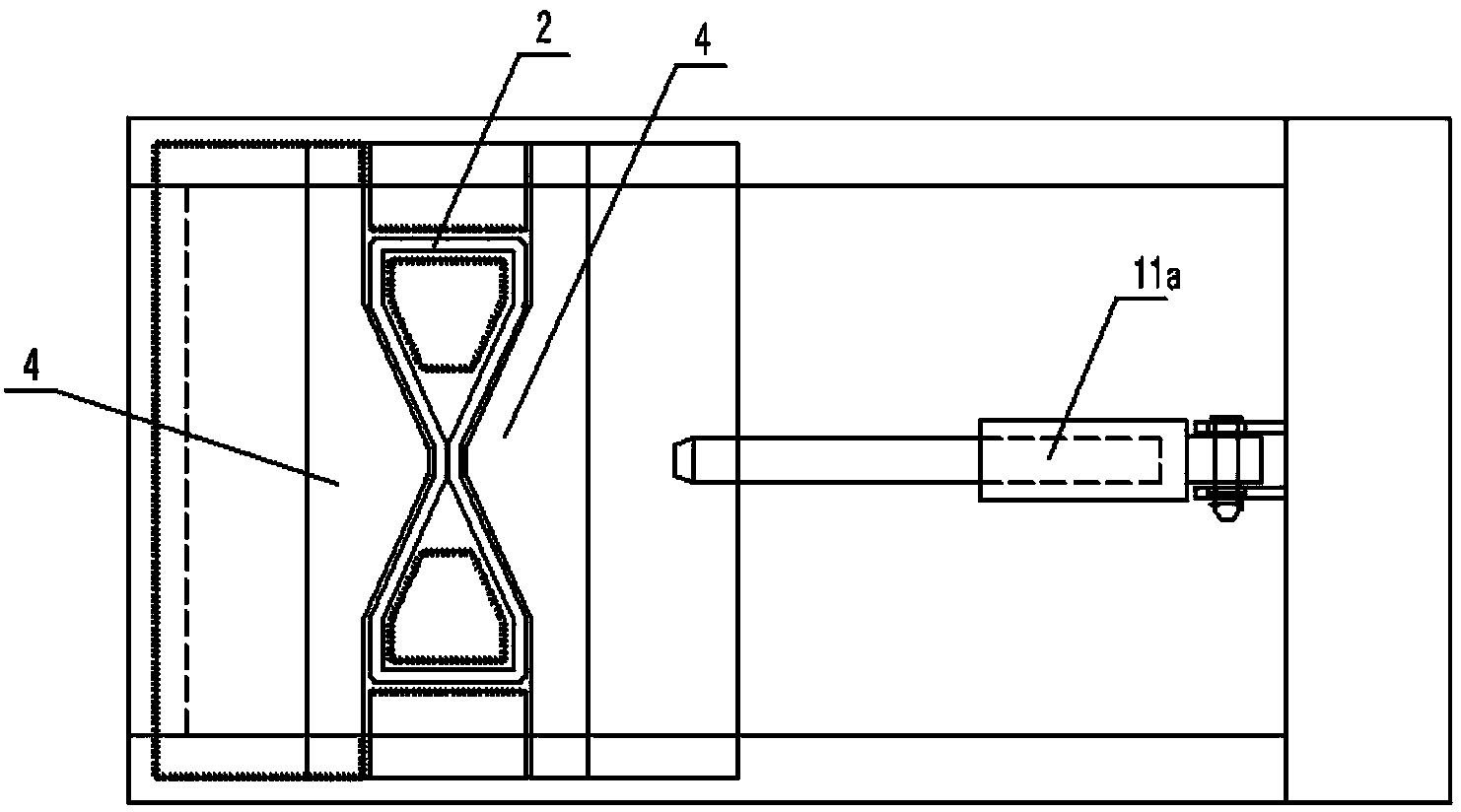

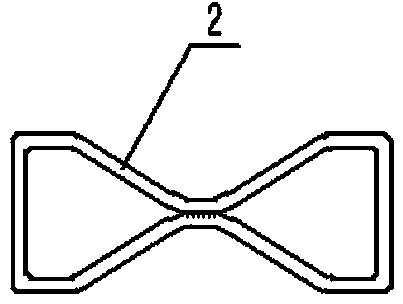

[0022] The "8" rib processing machine in this embodiment includes a horizontal processing unit and a vertical processing unit.

[0023] see figure 1 , figure 2 and image 3 , the horizontal processing unit is used to squeeze the horizontally placed rectangular steel frame 1 in the middle of the left and right frames until the left and right frames are closed in the middle, and weld the left and right frames at the closed position of the middle to form a horizontal "8" Word frame 2; the structure of the horizontal processing unit is set as follows: on the horizontal workbench, a pair of limit stoppers 3 are fixed according to the width and length of the rectangular steel bar frame 1, and the rectangular steel bar frame 1 is set on a pair of limit stoppers 3 On the left and right sides of the rectangular steel bar frame 1, a pair of horizontal "8" molds 4 are arranged opposite to each other in the shape of "8", and the horizontal "8" molds 4 can slide left and right under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com