Barrel flanger for automobile pre-silencer

A technology of muffler and flanging machine, which is applied to metal processing equipment, forming tools, manufacturing tools, etc. The side mold cannot be accurately aligned, etc., to achieve the effect of improving work efficiency and smoothing the port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

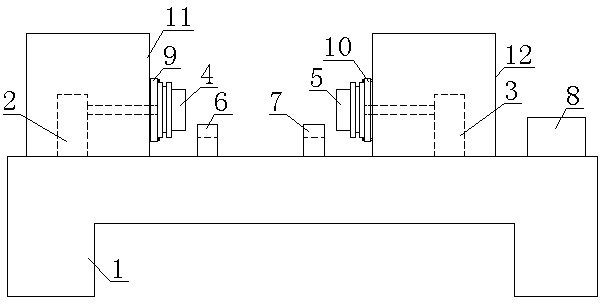

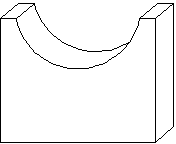

[0016] Such as figure 1 and figure 2 As shown, the barrel flanging machine used for the front muffler of automobiles includes a support platform 1, on which a left box body 11, a right box body 12, a left support seat 6, a right support seat 7 and an electric control box 8 are arranged. , wherein, left box body 11 is provided with left oil cylinder 2, and right box body 12 is provided with right oil cylinder 3. One end of the piston rod of the left cylinder 2 passes through the right side wall of the left cylinder 2 and is connected with a left flanging mold 4, and one end of the piston rod of the right cylinder 3 passes through the left side wall of the right cylinder 3 and is connected with a right flanging mold 5, and the left The flanging mold 4 corresponds to the right flanging mold 5 positions. Left supporting seat 6 and right supporting seat 7 are positioned between left flanging mold 4 and right flanging mold 5, and left supporting seat 6 is close to left box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com