Riveting machine

A technology of riveting machine and riveting components, which is applied in the field of mechanical equipment, can solve the problems of large moving distance of the riveting head, crushing of the workpiece to be riveted by the riveting head, time-consuming and labor-intensive problems, and achieves the effect of high safety and improved riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and structural, method, or functional transformations made by those of ordinary skill in the art based on these embodiments are all included in the protection scope of the present invention.

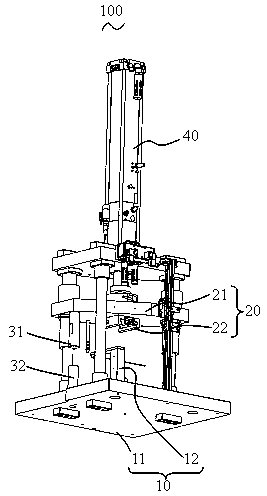

[0019] ginseng figure 1 As shown, the present invention provides a riveting machine 100 with high safety. During the riveting process, the riveting head 22 will not squeeze the workpiece to be riveted, thereby ensuring the safety of the workpiece to be riveted.

[0020] Wherein, the riveting machine 100 provided by the present invention includes:

[0021] A positioning assembly 10 for fixing a workpiece to be riveted, a riveting assembly 20 located above the positioning assembly 10, and a power assembly 30 connecting the riveting assembly 20, the power assembly 30 controls the riveting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com