Ceiling transport vehicle and article transport facility

A technology for transporting vehicles and roofs, which is applied in the direction of conveyor objects, conveyors, load blocks, etc., and can solve problems such as large spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

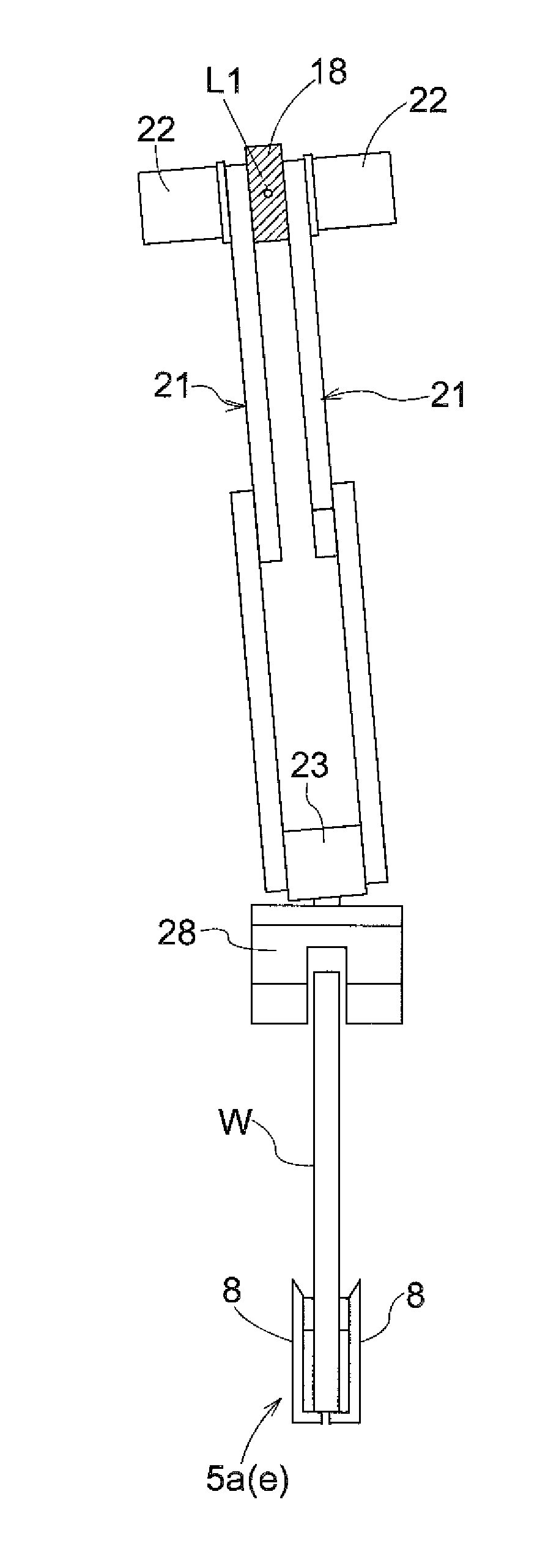

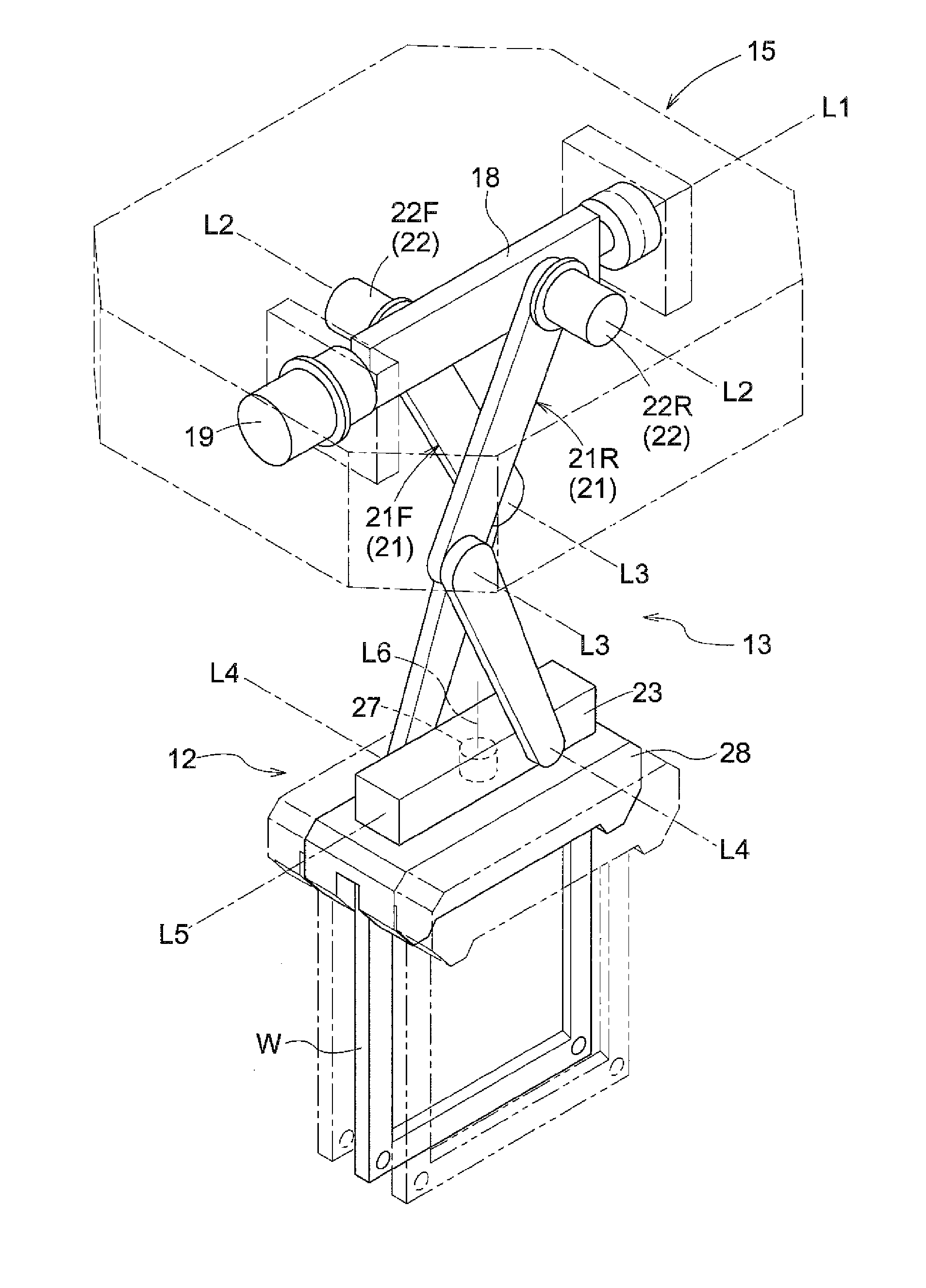

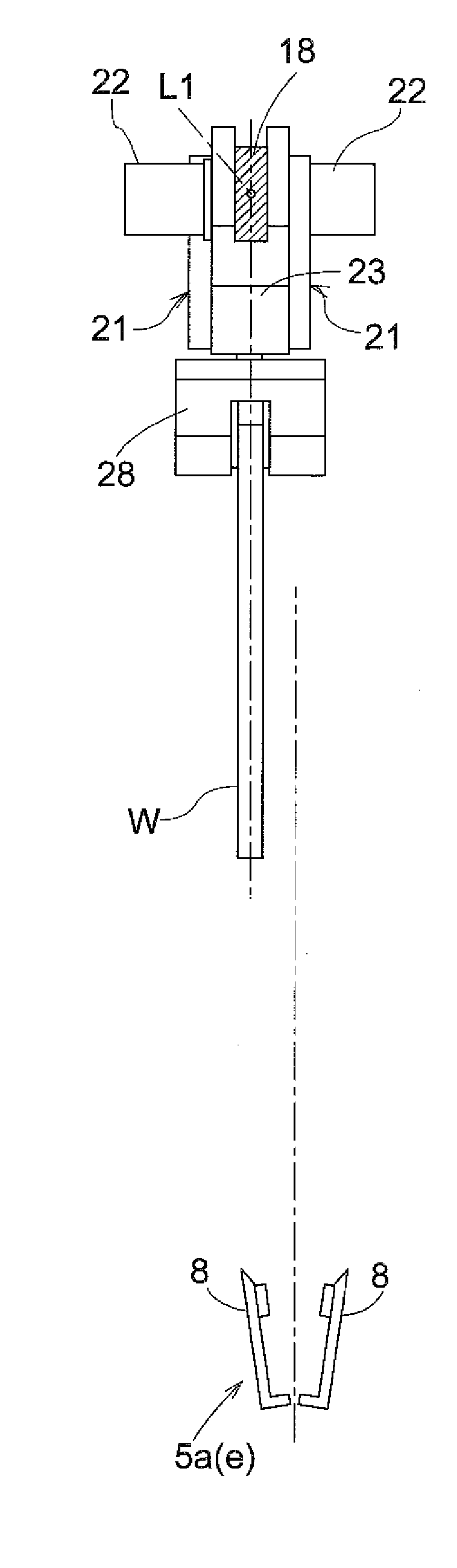

[0069] Embodiments of the present invention will be described below based on the drawings.

[0070] Such as figure 1 As shown, the ceiling conveying vehicle 1 equipped in the article conveying facility is configured to be guided and supported by the traveling rail 2 provided on the ceiling, and is configured to travel along the traveling path 3 passing above the conveying target position E to convey the formed object as an article. It is a plate-shaped substrate W. In addition, in this embodiment, as the board|substrate W, the photomask used for processing of the glass substrates, such as a liquid crystal panel, is conveyed by the top conveyance vehicle 1. As shown in FIG.

[0071] In addition, the horizontal direction along the traveling direction will be referred to as the front-rear direction, and the horizontal direction perpendicular to the front-rear direction will be referred to as the lateral width direction. exist figure 1 In , the front-rear direction is indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com