Overhaul construction method of double chute position of dry quenching furnace

A construction method and technology of dry quenching coke oven, applied in coke oven, petroleum industry, coke cooling and other directions, can solve the problems of long maintenance period, long downtime, short service life of support columns and partition walls, etc. The cost of the maintenance project, the quality of the maintenance construction, and the effect of enhancing the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A construction method for overhauling double chute parts of CDQ coke oven, which is characterized in that it includes the following steps:

[0035] a. Install ceiling facilities

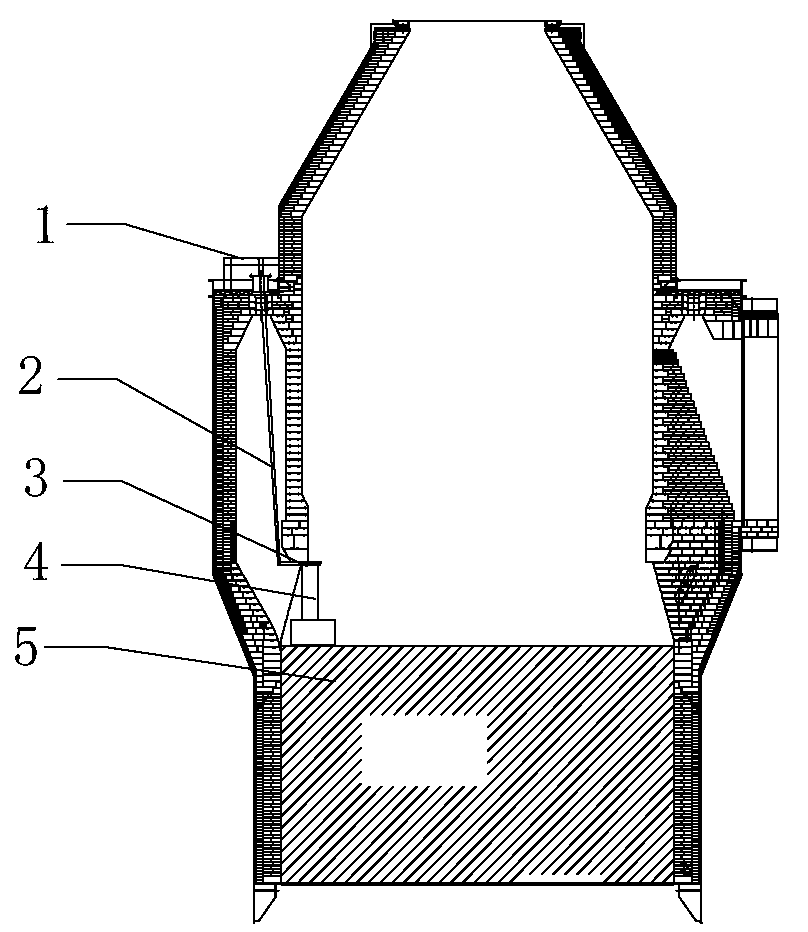

[0036] figure 1 It is a schematic diagram of the installation of the suspended ceiling technical measures of the embodiment of the present invention.

[0037] Lift the masonry on the upper part of the second-story arch of the double-chute support column with a spreader, connect and fix the support 1 from the fire viewing hole to the second-story arch support part 3 of the double-chute support column with the second-story arch tie rod 2 of the double-chute support column, At the same time, use 4 jacks to support and protect the lower part of the second-floor arch of the double ramp support column on the coke 5, so as to prevent the upper part of the masonry from sinking when the double ramp support column is disassembled for construction;

[0038] b. Remove the double ramp support column bric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com