Method for producing beta-amyrin with saccharomyces cerevisiae engineering bacterium

A technology of Saccharomyces cerevisiae and arysinol, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., which can solve the problems of low accumulation of β- arysinol and difficult synthesis by chemical methods, and achieve easy genetic manipulation , Simplify the fermentation process and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Construction of Saccharomyces cerevisiae Genetic Engineering Bacteria

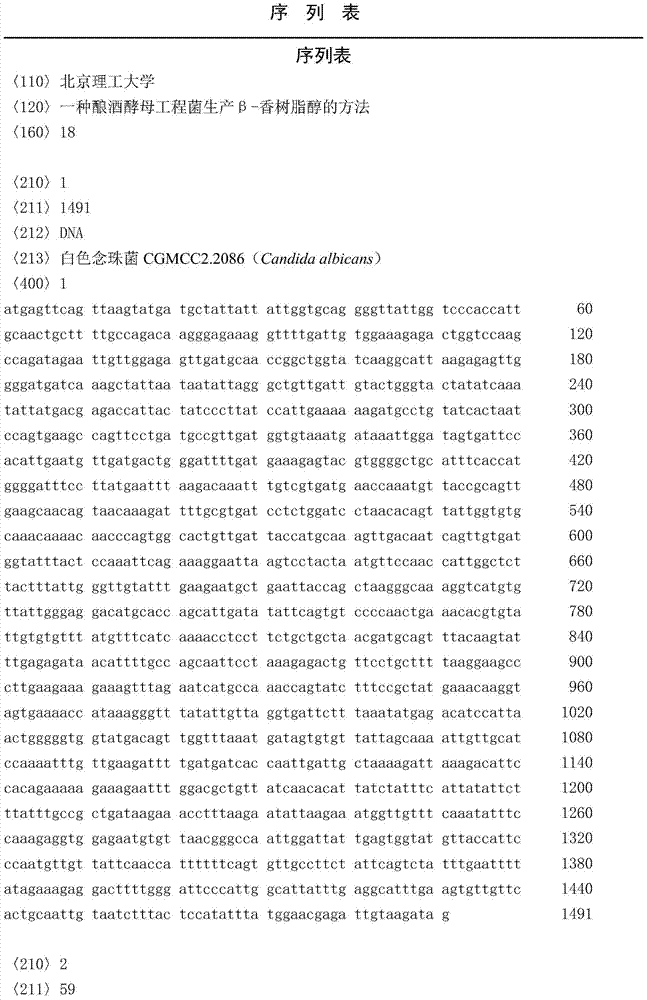

[0017] 1. The 2,3-oxidized squalene monooxygenase SQE gene fragment was cloned from Candida albicans CGMCC2.2086, which was consistent with the Candida albicans 2,3-oxidized squalene monooxygenase gene sequence published by Genbank (Genbank registration sequence number U69674) was compared by BLAST, and the homology analysis showed that the homology of the SQE gene fragment of the clone and the Candida albicans 2,3-oxidosqualene monooxygenase gene announced by the Genbank gene bank was 100% (such as SEQ ID shown in No.1).

[0018] The primer sequences are:

[0019] Primer 1: 5'> GATTAGCATCCATAACCGCATACTCTAATTGACGATAAC ATGAGTTCAGTTAAGTATGATYS1 overlapping sequences.

[0020] Primer 2: 5'> GCCAAGTAGGCAATTTTTAGTACTGTCAGTATTGTTAT CTATCTTACAATCTCGTTCCTYS1 overlapping sequences.

[0021] 2. Obtained the bAS gene fragment of Glycyrrhiza glabra β-amyresinol synthase (Genbank registratio...

Embodiment 2

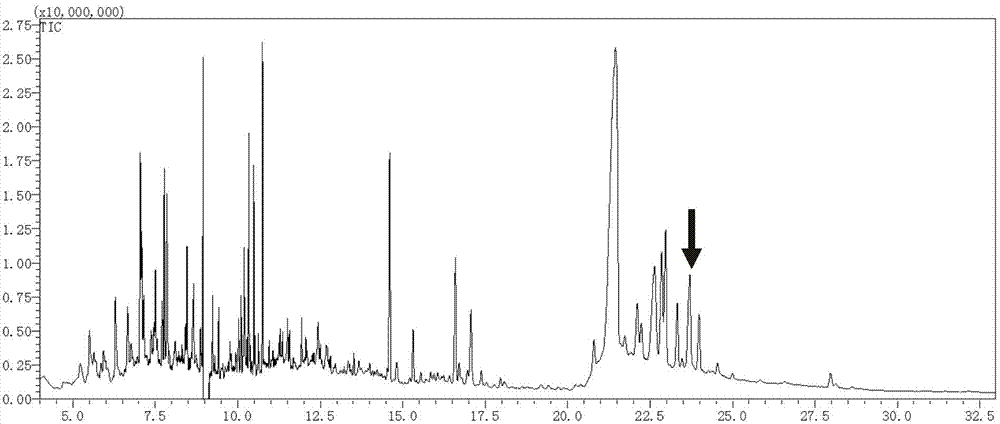

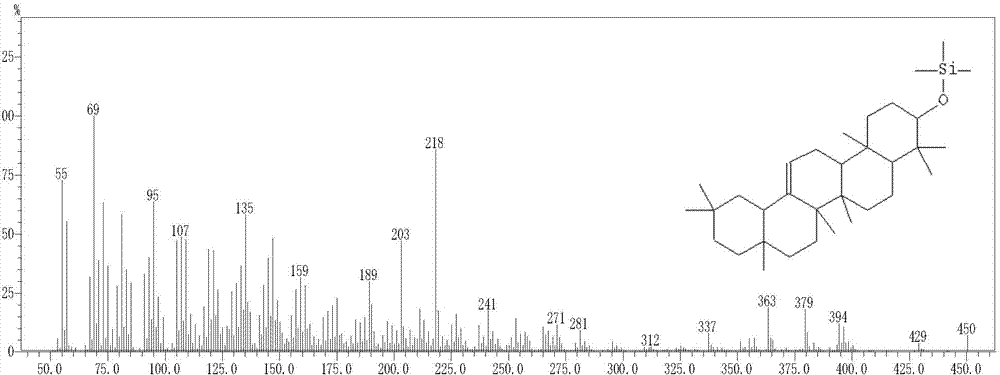

[0050] Example 2: Verification of Saccharomyces cerevisiae Engineering Bacteria Fermentative Production of β-Arysinol

[0051] Select the Saccharomyces cerevisiae engineered bacterium screened out in Example 1, culture in a shake flask at 30° C. in a medium containing 2% glucose, 2% peptone and 1% yeast powder, centrifuge at 5000 rpm for 5 min after 5 days, and use 10 mL of 20% hydrogen for precipitation Resuspend in potassium oxide solution (containing 50% ethanol), then boil in boiling water for 10 min, extract twice with n-hexane after cooling at room temperature, combine the extracts and concentrate to 1 mL, then add 100 μL of pyrimidine and 50 μL of N,O to the concentrated solution -Bis(trimethylsilyl)trifluoroacetamide, react at 37°C for 2h. Shimadzu gas chromatography-mass spectrometry instrument GCMS-QP2010 equipped with Agilent chromatographic column DB-1 (30m*0.25mm*0.25um) was used to analyze the fermentation production of β-amyresinol by Saccharomyces cerevisiae en...

Embodiment 3

[0052] Example 3: Application of Saccharomyces cerevisiae Engineering Bacteria in the Fermentative Production of β-Arysinol

[0053] Seed liquid culture: Pick the single colony of Saccharomyces cerevisiae engineered bacteria screened in Examples 1 and 2 from the plate, inoculate in 40mL medium containing 2% glucose, 2% peptone and 1% yeast powder, 30°C, 170rpm Shake culture for 36h.

[0054] Fermentation test: Transfer the inoculum solution to a 300mL shake flask filled with 100mL fermentation medium (2% glucose, 2% peptone, 1% yeast powder, pH7.0) according to the inoculum size of the initial absorbance value of 0.10, 30°C, 170rpm Shake culture for 120 hours, sampling once every 24 hours, and measure the content of β-amyresinol in Saccharomyces cerevisiae cells. The results showed that the content of β-amyresinol reached 11.7 mg / L after fermentation of S. cerevisiae engineered bacteria.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com