A kind of enhanced long auger bored pressure grouting concrete pile and its construction method

A long-spiral drilling and concrete pouring technology, which is applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems such as failure to effectively control the shape of the slurry, inability to effectively control the shape of the slurry, and difficulty in effectively exerting the bearing capacity. The effect of improving the utilization rate of slurry, increasing the side friction resistance and increasing the diameter of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Reinforcement (steel pipe) connection construction technical requirements, pile body concrete design and construction technical requirements, prestressed reinforced concrete stiffener stacking and hoisting technical requirements, grouting body mix ratio design and construction technical requirements, pile bottom grouting pipe and pile end The technical requirements for the connection and grouting construction of the expanded bottom bag will not be repeated in this embodiment, and the embodiments of the structure involved in the present invention will be focused on.

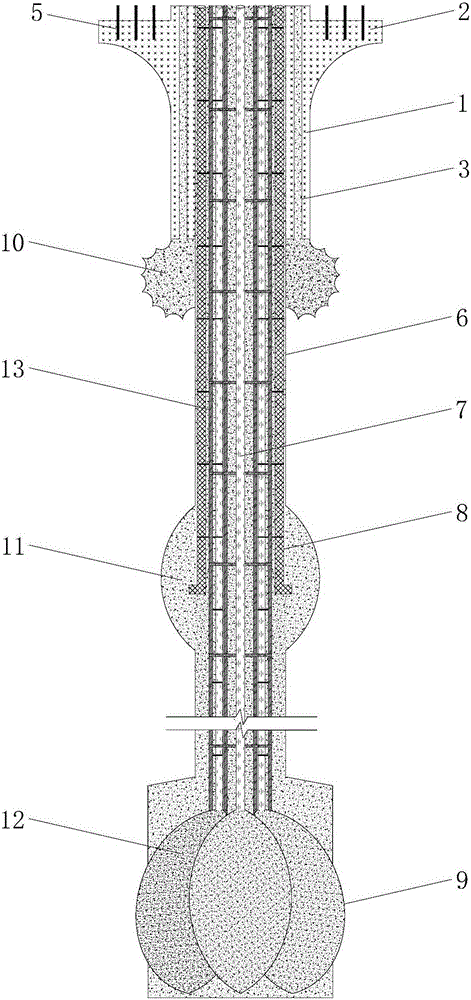

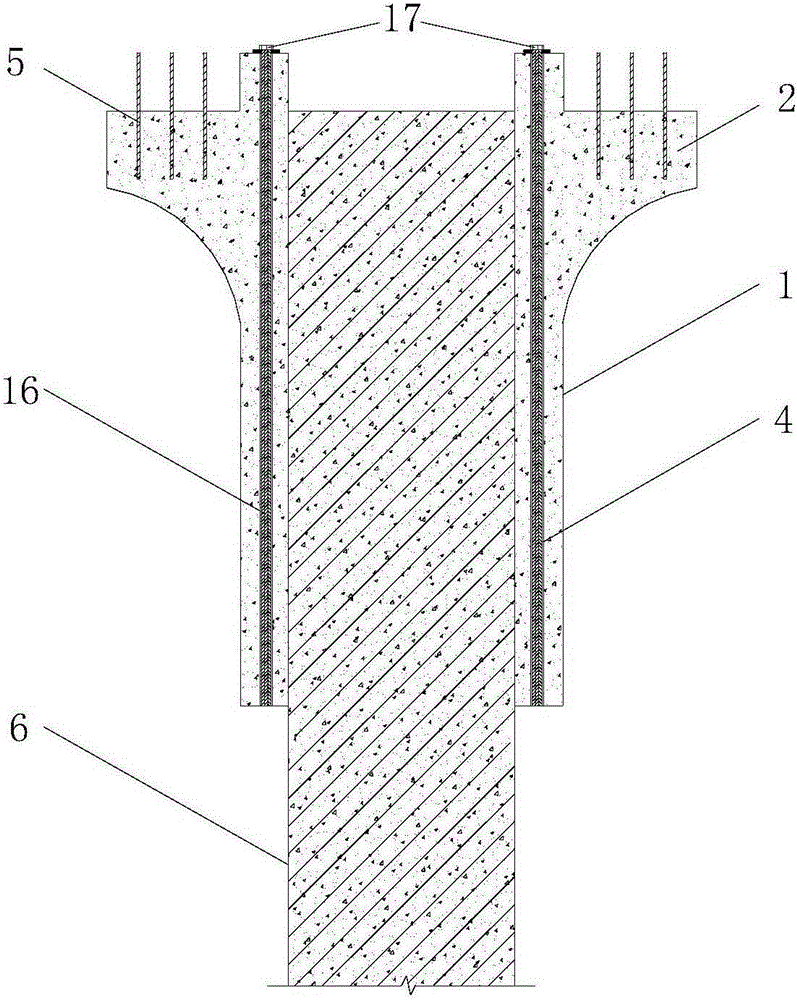

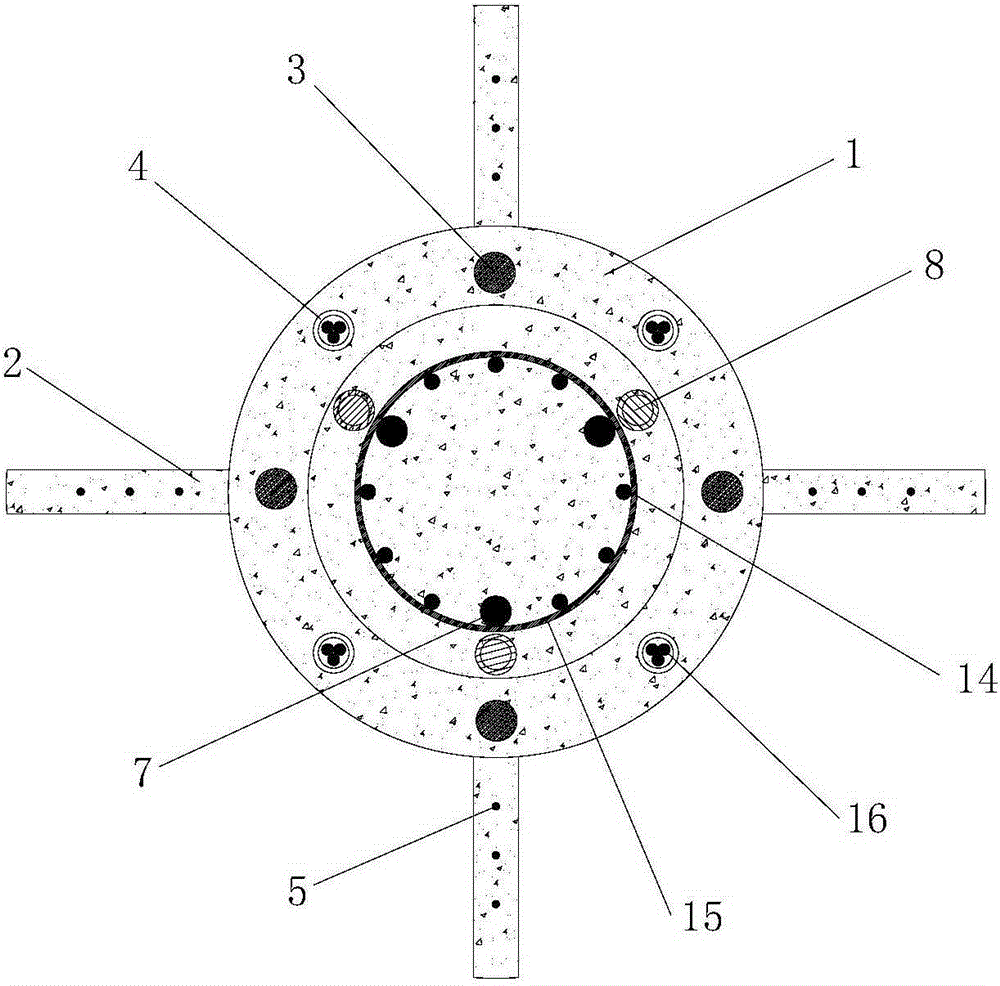

[0045] figure 1 It is a cross-sectional view of the reinforced long helical drilled concrete pile of the present invention, figure 2 is a cross-sectional view of a prestressed reinforced concrete stiffener, image 3 is the cross-sectional view of the reinforced concrete pile at the top of the pile, Figure 4 is the cross-sectional view of the pile side grouting expansion body, Figure 5 It is a schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com