Lithium ion battery end cover

A lithium-ion battery and end cap technology, applied in battery pack components, battery boxes/jackets, small-sized batteries/battery packs, etc., can solve problems such as deformation of rubber plugs, battery leakage, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

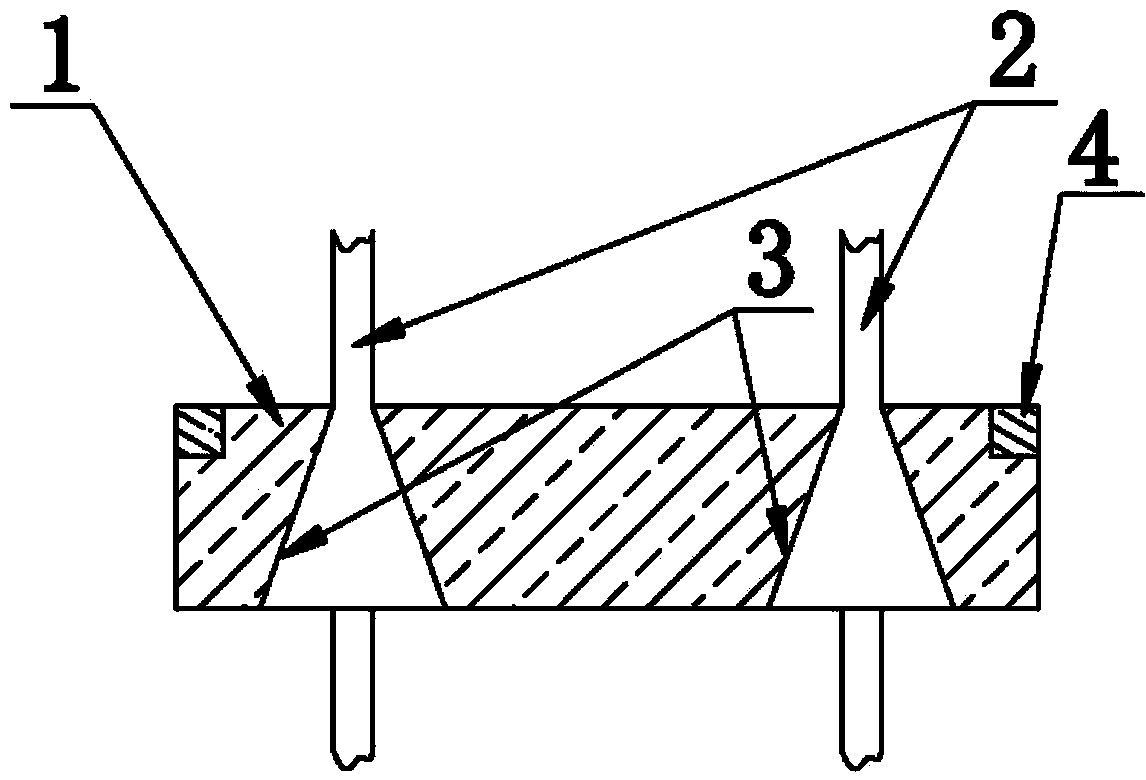

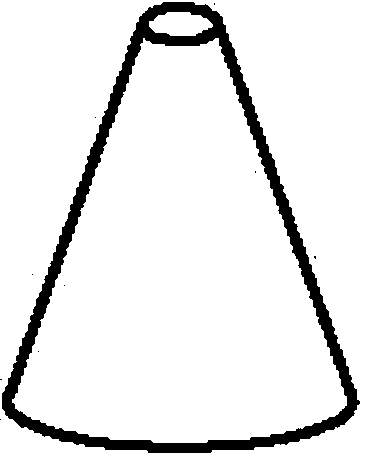

[0025] Depend on figure 1 , figure 2 It can be seen that a lithium-ion battery end cover includes a cover body 1, positive and negative electrode guide pins 2 pierced through the cover body 1, and a section of the guide pin 2 located in the cover body 1 is provided to prevent the guide pin 2 from coming out of the cover body. 1, the guide pin holder 3, the cover body 1 is injection molded from a thermoplastic resin resistant to 90°C, and the section of the guide pin 2 located in the cover body 1 and the guide needle holder 3 are integrally injected into the cover body 1.

[0026] The cover body 1 of the present invention can be made of polycarbonate (PC) or AS styrene-acrylonitrile copolymer or polyethylene (PE) by injection molding (the styrene-acrylonitrile copolymer used in this embodiment).

[0027] The guide pin 2 and the guide pin seat 3 of the present invention are all made of conductive metal, the positive pole is made of aluminum, and the negative pole is made of al...

Embodiment 2

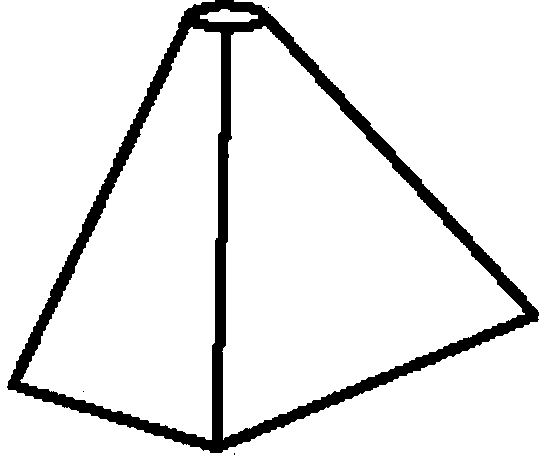

[0031] Depend on figure 1 , image 3 It can be seen that the guide needle holder 3 in this embodiment is in the shape of a pyramid.

[0032] The rest are the same as embodiment 1.

Embodiment 3

[0034] Depend on Figure 4 , Figure 5 It can be seen that a lithium-ion battery end cover includes a cover body 1, positive and negative guide pins 2 whose tails are located in the cover body 1, the tails of the guide pins 2 are each provided with a guide pin seat to prevent the guide pins 2 from falling out of the cover body 1 3. The guide pin seat 3 at the tail of the positive and negative guide pins 2 is integrally injected into the cover body 1, and the guide pin seat 3 is made of conductive material, and the bottom of the guide pin seat 3 is flush with the bottom of the cover body 1, so as to connect the battery pole piece.

[0035] In order to prevent the guide needle 2 from falling out in the present invention, the guide needle seat 3 includes an anti-falling cone 31 and a connection base 32 located below the anti-falling cone 31. The bottom of the connection base 32 is flush with the bottom of the cover body 1; The area of the bottom surface of the anti-off cone 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com