Three-dimensional follow-up constant force hanging device

A hanging device, three-dimensional technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, bearings, etc., can solve the problems of large measurement error, large influence of inertial force of weight reduction weight, low follow-up accuracy, etc. To achieve the effect of improving accuracy and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

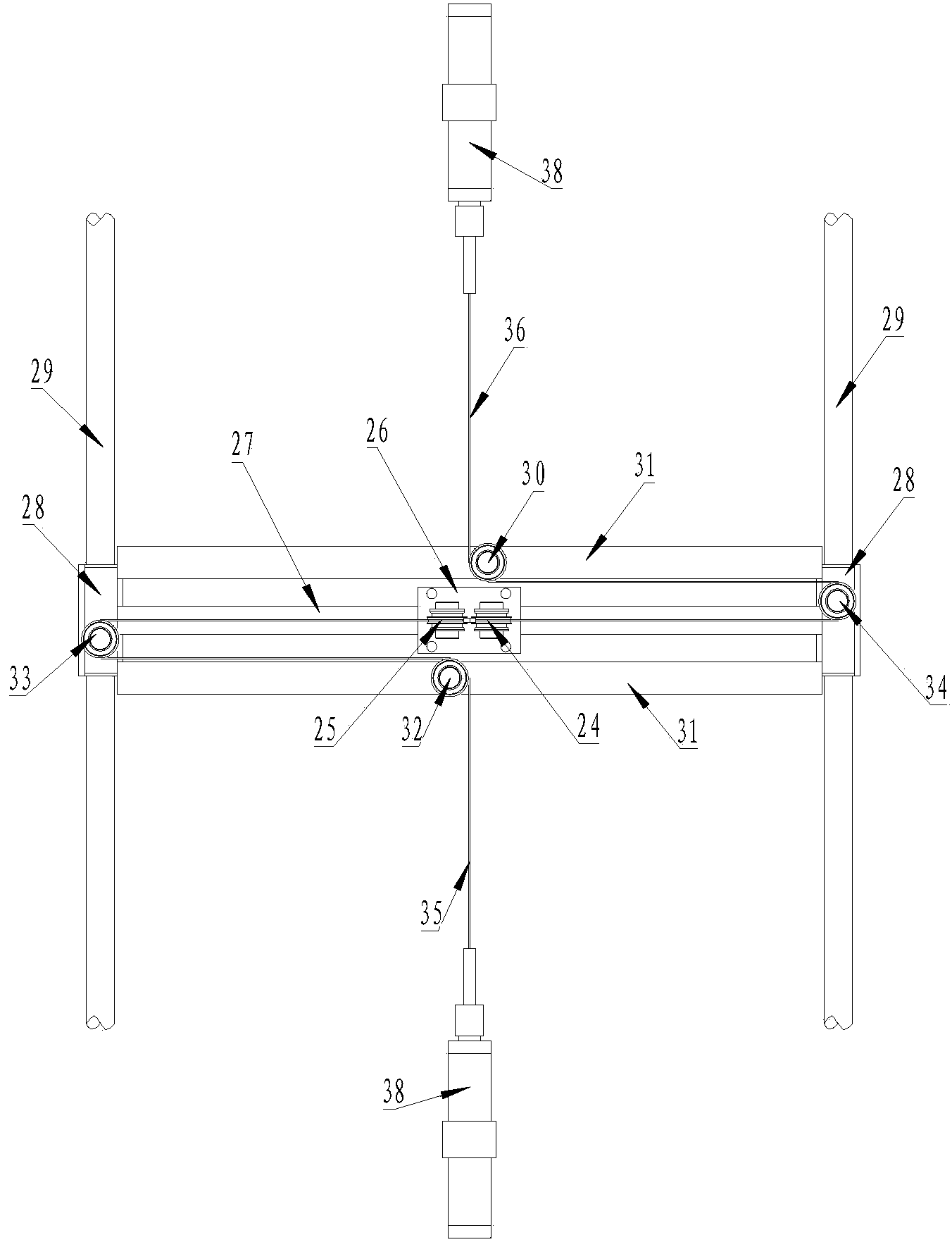

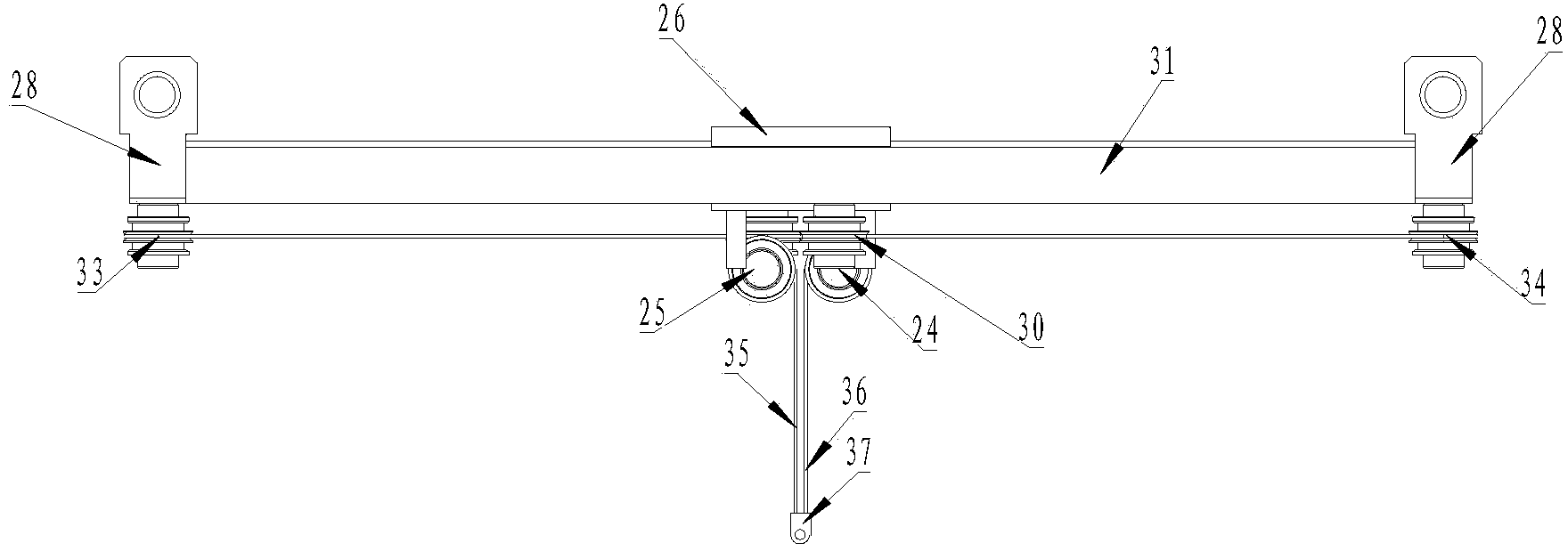

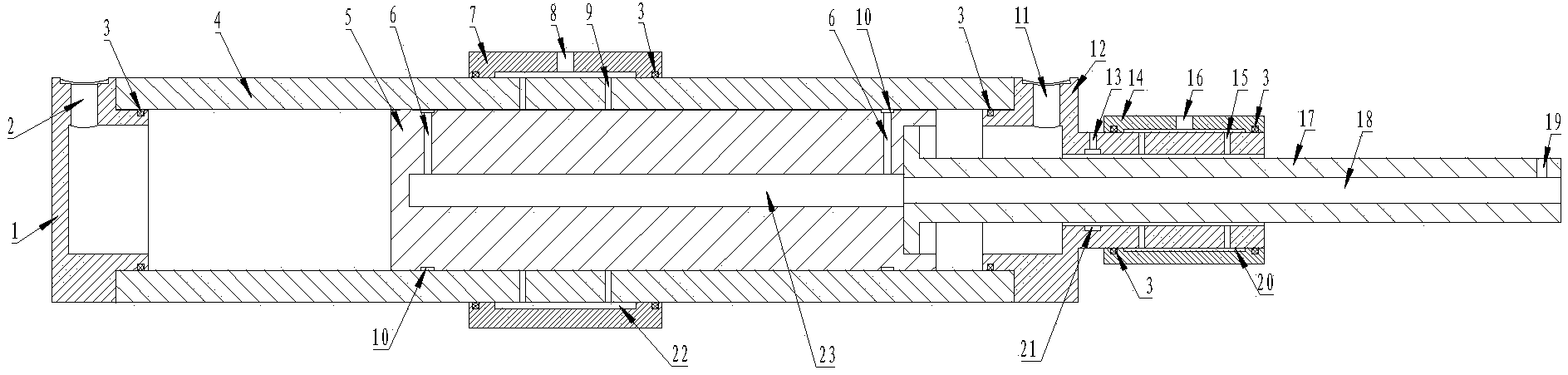

[0029] A three-dimensional following constant force suspension device, comprising an air-floating guide rail, a constant force output device, a pulley block, and a suspension rope.

[0030] The air bearing guide rail includes a horizontal air bearing shaft 27, a horizontal air bearing sleeve 26, a longitudinal air bearing shaft 29 and a longitudinal air bearing sleeve 28, the horizontal air bearing sleeve 26 is set on the horizontal air bearing shaft 27, and the two ends of the horizontal air bearing shaft 27 Two longitudinal air bearing sleeves 28 are fixedly connected, and the longitudinal air bearing sleeve 28 is set on the longitudinal air bearing shaft 29. The horizontal support 31 is connected between the two longitudinal air bearing sleeves 28. There are two horizontal brackets 31 and are located on the horizontal air bearing shaft. 27 sides.

[0031] The pulley block comprises two vertically installed first fixed pulleys 25, the second fixed pulley 24 and the third fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com