Automatic consecutive plug-in mounting device and method for firework paper tube fuses

A paper tube leading and automatic technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of unfavorable mass production of fireworks products, time-consuming and labor-intensive, low operating efficiency, etc., to improve production efficiency, reduce labor costs, The effect of reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

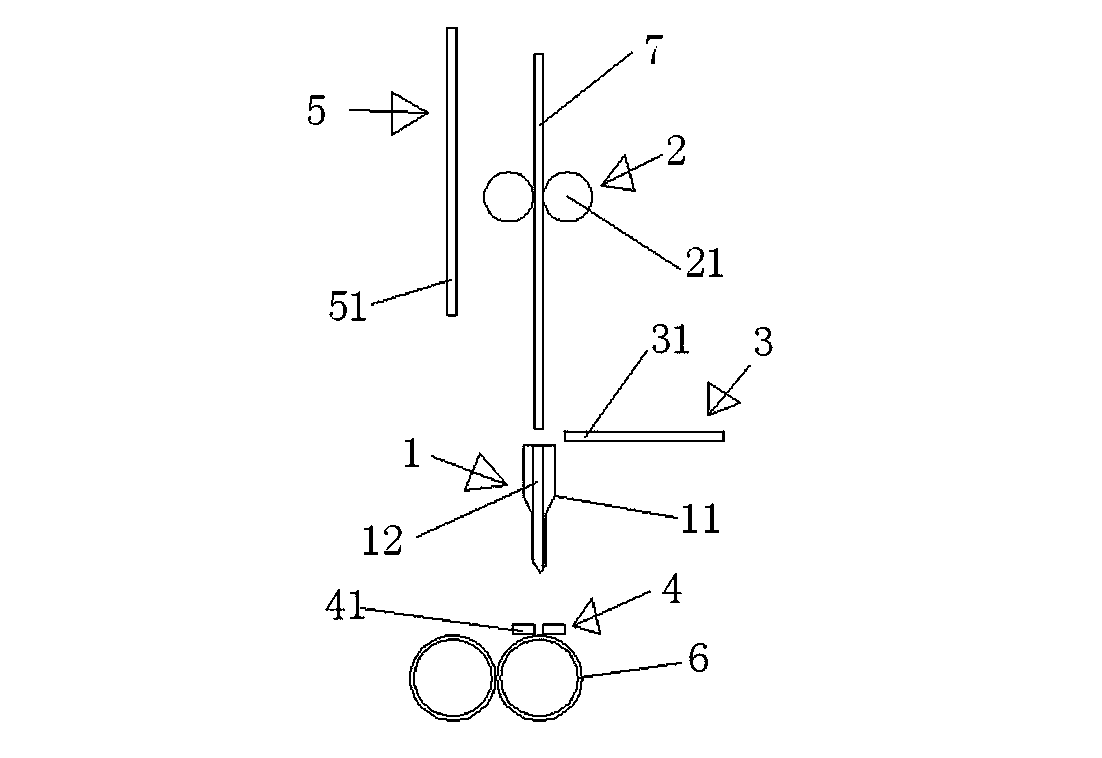

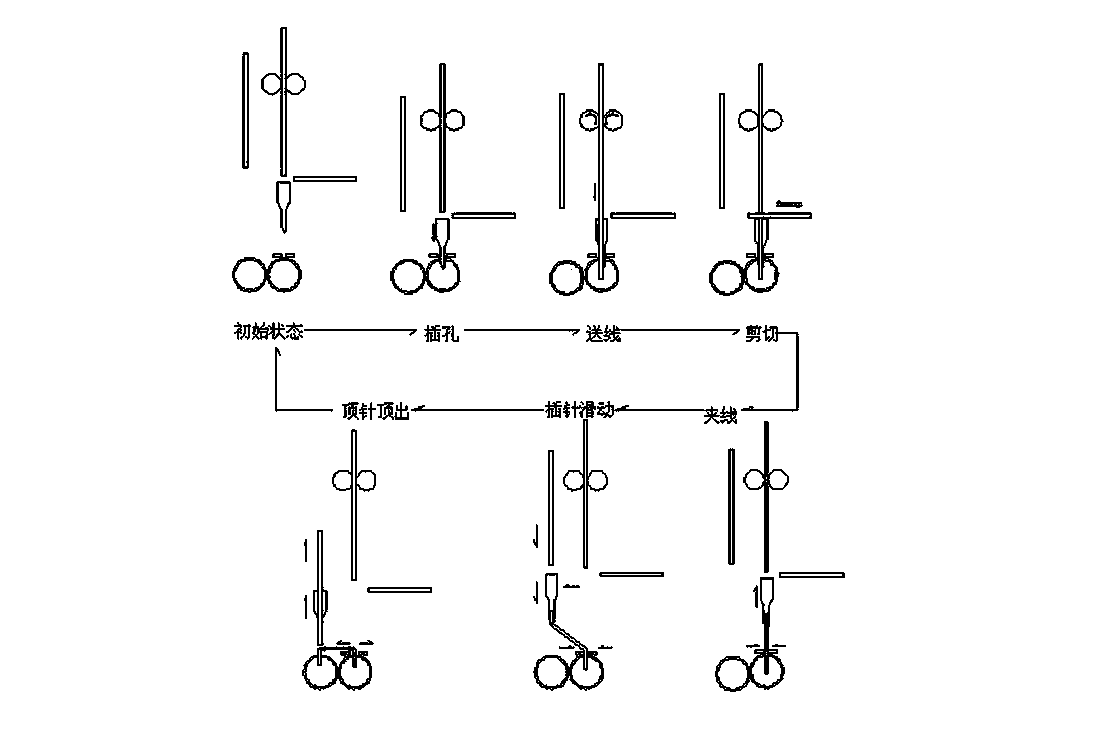

[0034] like figure 1 and figure 2 As shown, a continuous automatic insertion device for fireworks paper tube leads is characterized in that it includes a needle insertion mechanism 1, a wire feeding mechanism 2, a shearing mechanism 3, an anti-off device 4 and a thimble mechanism 5, and the wire feeding mechanism, The pin insertion mechanism, the anti-off device and several paper tubes 6 to be inserted are arranged vertically in sequence, (in this example: the paper tubes are horizontally arranged side by side, and the side faces the pin insertion mechanism, but other ), the pin insertion mechanism can insert the jacks on the several paper tubes, the wire feeding mechanism can drive the lead wire 7 to be inserted into the pin insertion mechanism, and the shearing mechanism can cut off the The lead wire, the anti-loosening device can locate the lead wire, and the ejector mechanism can eject the lead wire from the pin insertion mechanism.

[0035] Preferably, the structure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com