Special clamping device for measuring perpendicularity of auxiliary tooth handle and tooth top

A technology of clamping equipment and verticality, applied in the field of special clamping equipment, can solve the problems of difficult to guarantee detection accuracy, affecting work efficiency, complicated measurement process, etc., saving time and effort, improving measurement efficiency, and accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

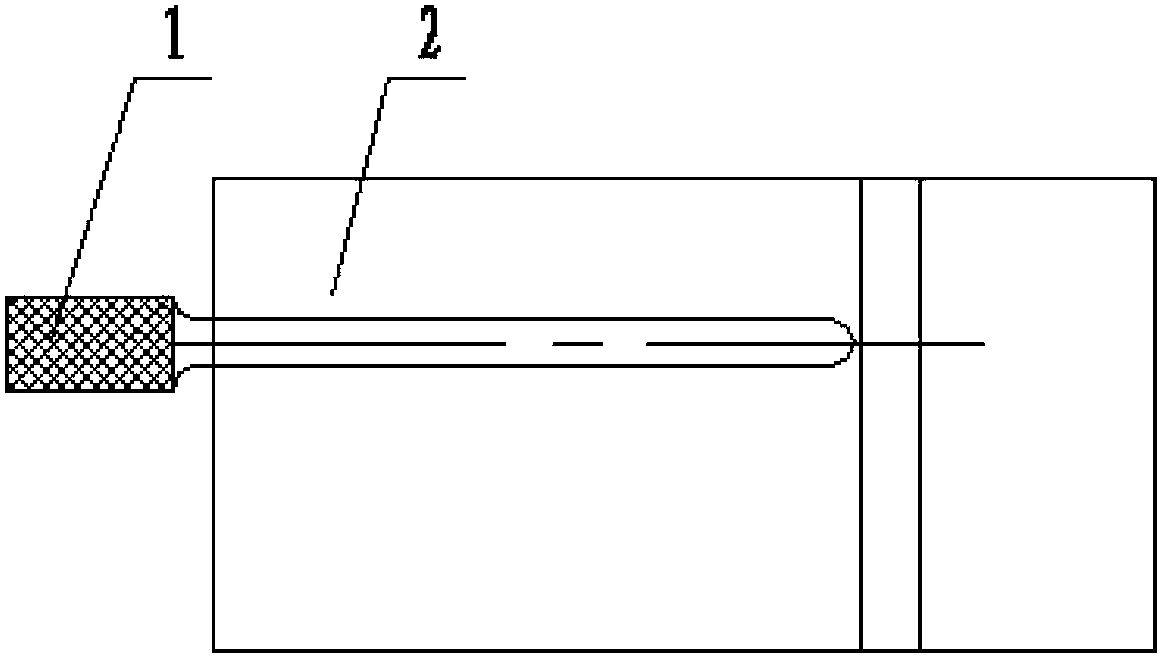

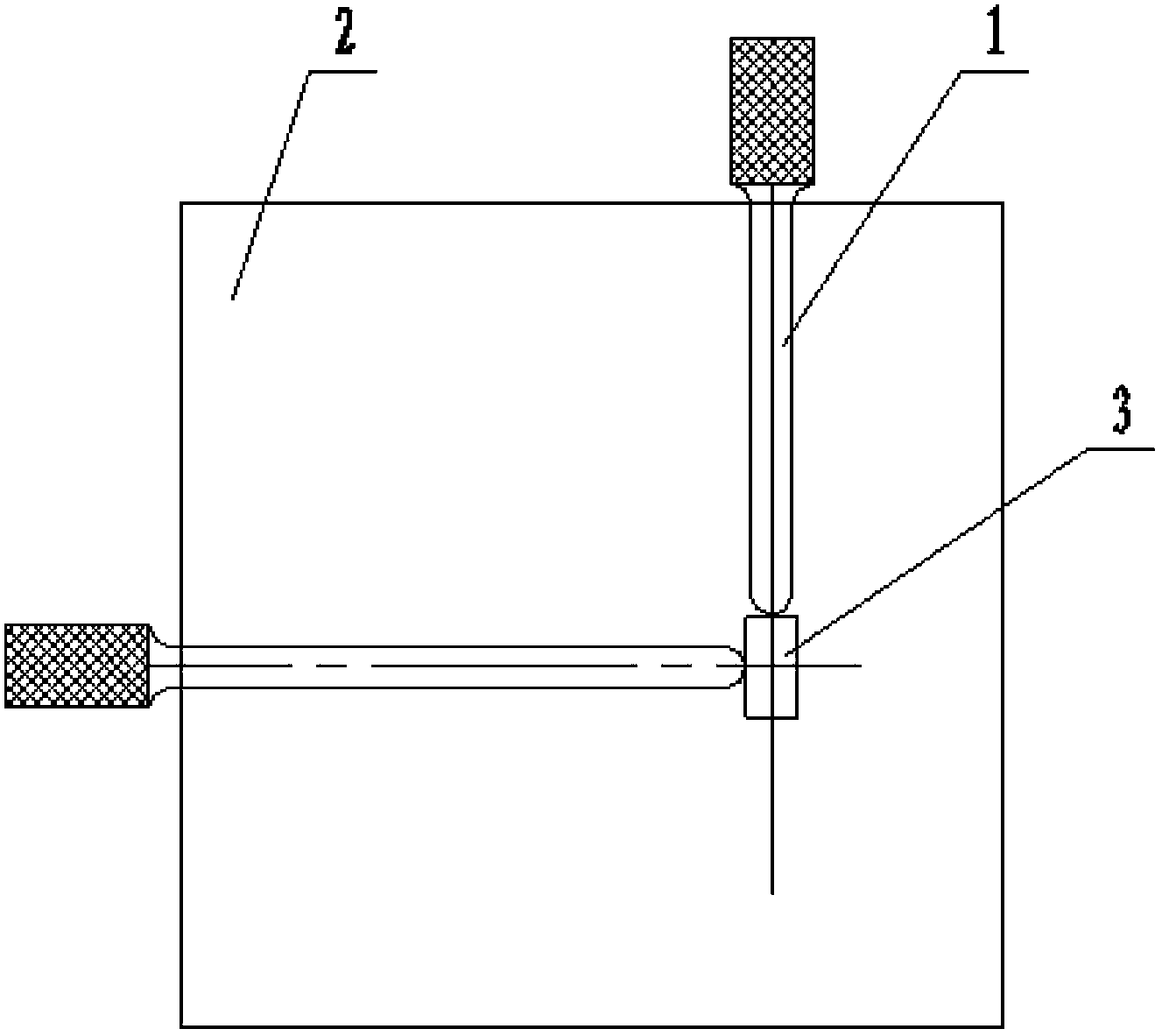

[0015] A special clamping device for measuring the verticality between the handle of the auxiliary tooth and the crest of the tooth, including a base 2, on which a vertical insertion hole 3 is made, and the insertion hole is perpendicular to the upper surface of the base , the handle of the workpiece to be tested can be inserted into the insertion hole. Two top wires 1 are worn on the base, the two top wires are installed horizontally, and the two top wires are arranged vertically to each other. The front ends of the two jacking wires both extend into the insertion holes, and are used for jacking on the workpiece for fixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com