Mounting structure of flocculation module and flocculation washing machine

An installation structure, washing machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems that affect the full play of the washing machine function, the water-saving tank function, the unfavorable transportation, the recycling process, the complex structure of the washing machine, etc. Promotion and use, simple structure and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

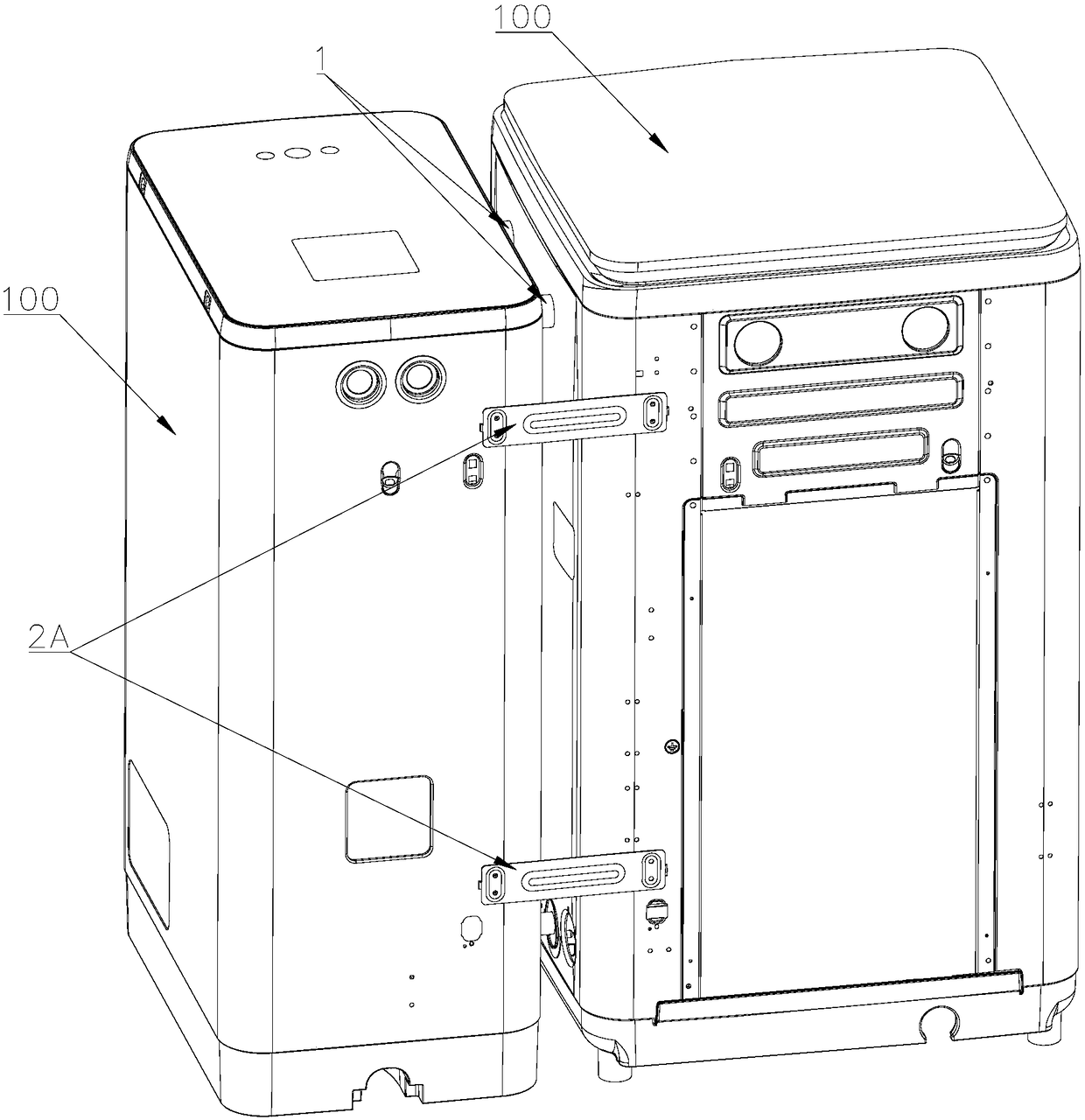

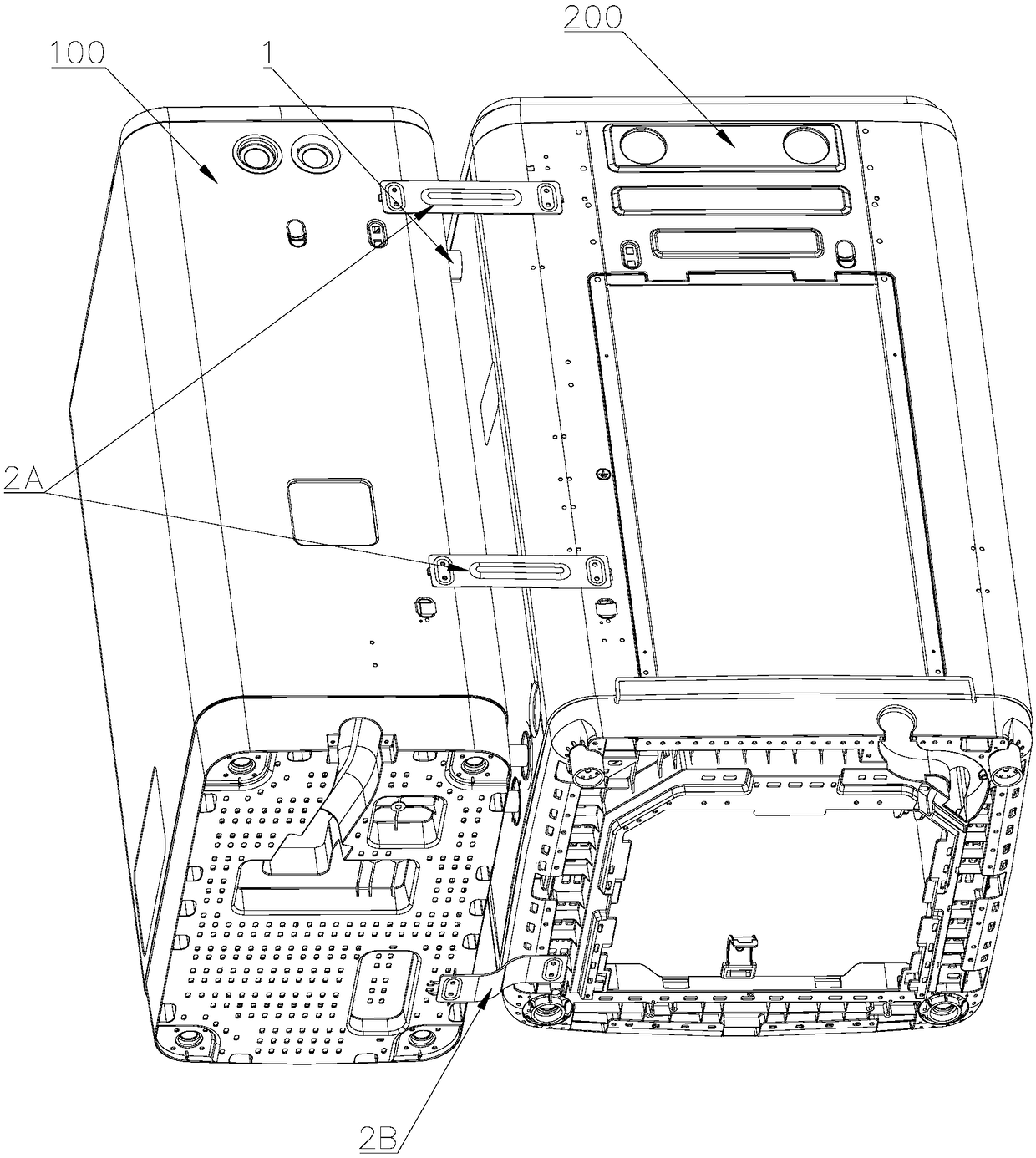

[0035] Such as Figure 1 to Figure 5 As shown, in this embodiment, the flocculation module 100 is installed on one side of the washing machine body 200, a first connector 1 is provided between the flocculation module 100 and the corresponding surface of the washing machine body 200, and one end of the first connector 1 is connected to the flocculation module. 100 is fixed or integrally connected, and the other end extends horizontally and is plugged and connected with the washing machine body 200 to realize the pre-positioning of the installation between the flocculation module 100 and the washing machine body 200, so that the flocculation module 100 and the washing machine body 200 can be inserted. to pre-connect.

[0036] Preferably, two or more first connectors 1 may be provided between the flocculation module 100 and the corresponding surface of the washing machine body 200, so that the plug connection points between the flocculation module 100 and the washing machine body...

Embodiment 2

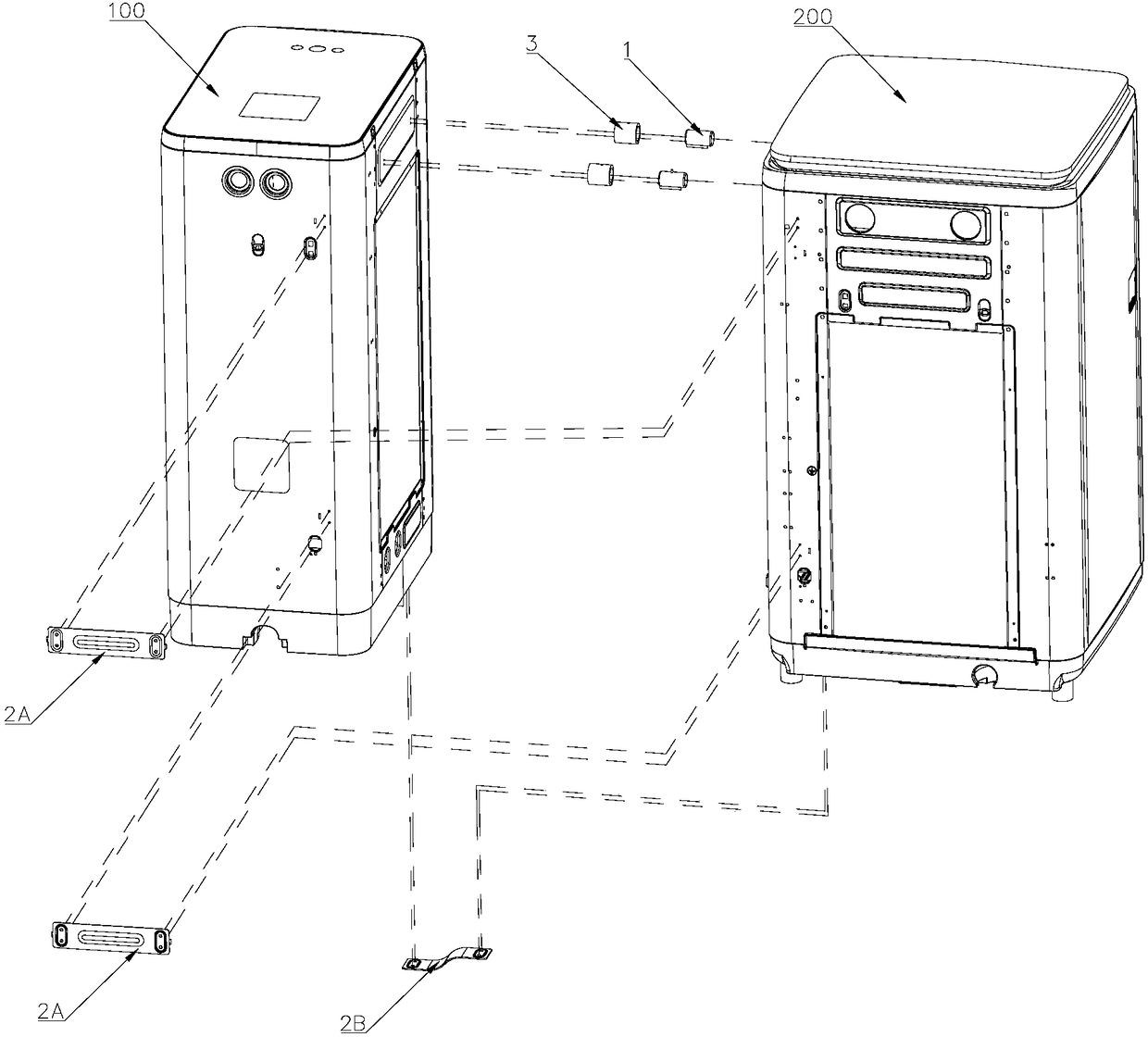

[0044] In this embodiment, the flocculation module 100 is installed on one side of the main body of the washing machine 200, and the rear side of the flocculation module 100 is in the same vertical plane as the main body 200 of the washing machine; The bottom of the flocculation module 100 and the bottom of the washing machine body 200 are connected through at least one second connecting piece 2B. The second connectors 2A, 2B straddle the seam between the flocculation module 100 and the washing machine body 200, and the two ends of the second connectors 2A, 2B are respectively attached to the outer walls of the washing machine body 100 and the flocculation module 200 and connected by bolts, so that The flocculation module 100 and the washing machine body 200 are screwed and assembled through the second connectors 2A and 2B, so that the flocculation module 100 and the washing machine body 200 are securely installed and fixed.

[0045] In this embodiment, the flocculation module...

Embodiment 3

[0050] Such as Figure 1 to Figure 5 As shown, in this embodiment, the washing machine body 200 and the flocculation module 100 are connected through the first connecting piece 1 described in the above-mentioned embodiment 1, and connected through the second connecting pieces 2A and 2B described in the above-mentioned embodiment 2. The connection makes the installation structure between the flocculation module 100 and the washing machine body 200 more reliable and stable.

[0051] In this embodiment, the assembly of the flocculation module and the installation on the body of the washing machine are as follows:

[0052] Step 1. Assemble the two first connectors 1, and put the buffer washer 3 on the outer periphery of the cylindrical body 4 constituting the first connector 1;

[0053] Step 2: Connect one end of the cylindrical body 4 of the two first connectors 1 to the flocculation module 100 to be screwed and fixedly connected respectively;

[0054] Step 3: Insert and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com