Pouring device for polyurethane rubber production

A polyurethane rubber, pouring box technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of equipment vibration, equipment loud noise, affecting the working environment of the device, etc., to increase work efficiency and improve work. The effect of environment and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

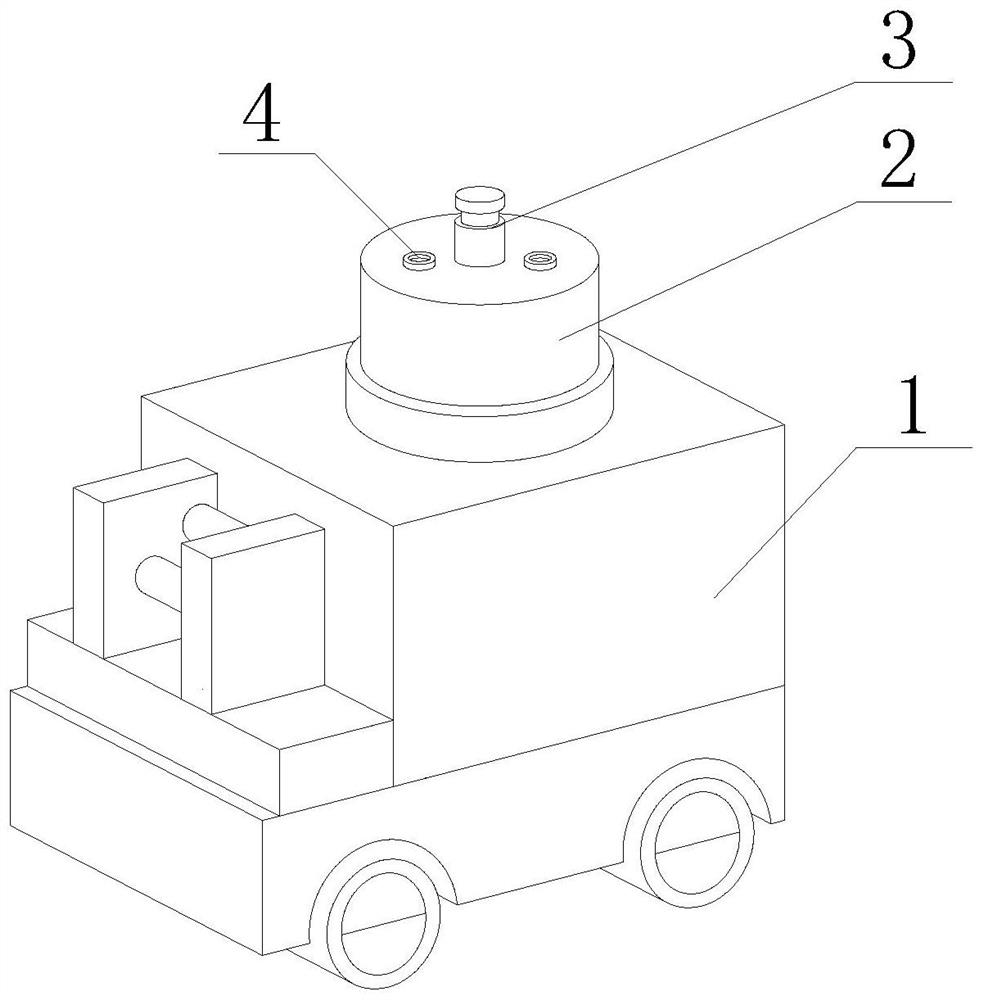

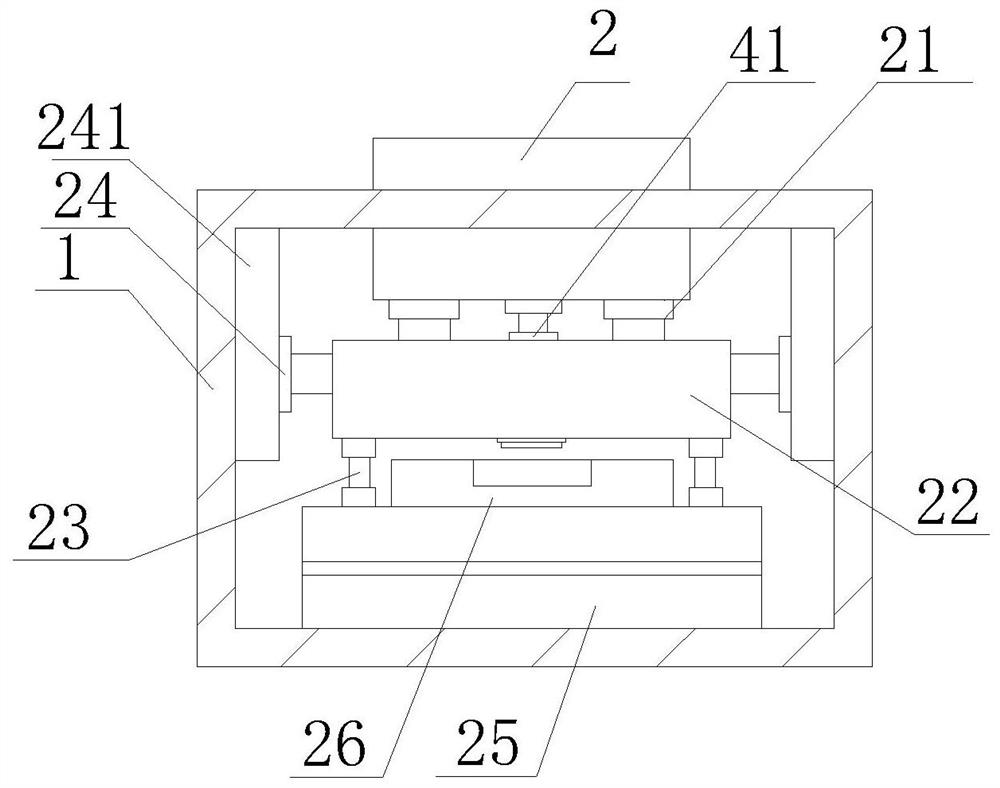

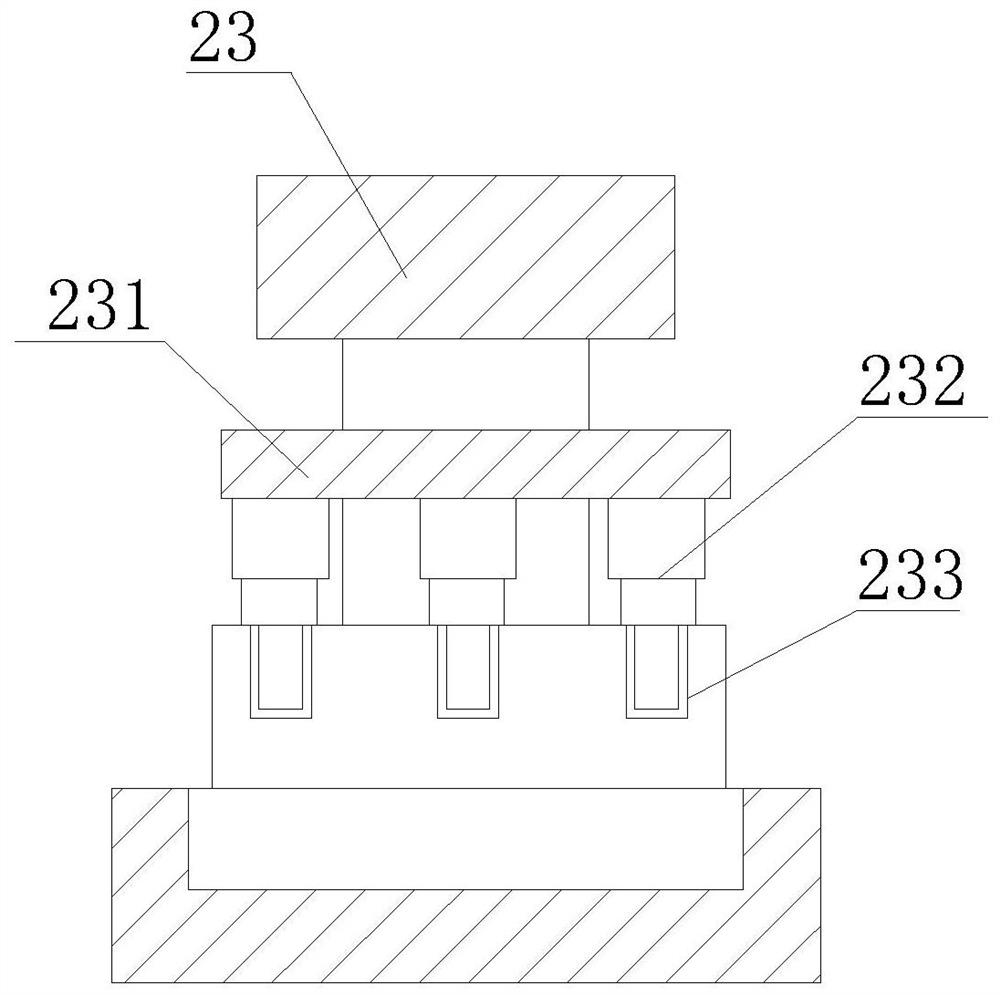

[0034] Such as Figure 1-8 As shown, the present invention provides a pouring device for polyurethane rubber production, comprising a pouring box main body 1, a stamping pipe 2, a stamping pump 3 and a feeding port 4, the top of the pouring box main body 1 is provided with a stamping pipe 2, and the stamping pipe 2 A stamping pump 3 is fixedly installed on the top of the stamping pump 3, and a feeding port 4 is provided on both sides of the stamping pump 3. The bottom of the stamping tube 2 is provided with a connecting column 21, and the bottom of the connecting column 21 is provided with an upper mold 22. The side is provided with stamping column 23, and the bottom of stamping column 23 is provided with pouring mold 25, and the outer side of stamping column 23 is provided with limit ring 231, and the bottom of limit ring 231 is fixedly installed with buffer column 232, and the bottom of buffer column 232 is provided with buffer block, the top of the buffer block has a buffer...

Embodiment 2

[0037] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, both sides of the upper mold 22 are fixedly connected with slide bars 24, and the sides of the slide bar 24 are movably sleeved with slide rails 241, and the slide rails The other side of 241 is fixedly installed in the inner side of pouring box main body 1.

[0038] In this embodiment, when the upper mold 22 is moving and stamping, the slide bar 24 is driven to move, so that the slide bar 24 moves on the slide rail 241, and then the stamping column 23 is used to limit and fix the position to achieve the stamping positioning of the mold. Function, convenient and convenient positioning of the device.

Embodiment 3

[0040] Such as Figure 1-8 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, the top of pouring mold 25 is fixedly installed with pouring block 26, and the top of pouring block 26 is provided with pouring groove 261, and pouring groove 261 inner cavity The bottom of the ejector plate 262 is provided with an ejector mechanism, and the ejector mechanism includes a lifting column 2621. Sliding column 2622, fixed block 2626 is fixedly installed on both sides of sliding column 2622, one side of fixed block 2626 is fixedly connected with moving bar 2624, the other end of moving bar 2624 is provided with moving block 2623, and the top of moving block 2623 is fixedly installed with Push rod 2625, the push rod 2625 is arranged at the bottom of the ejector plate 262, heating blocks 263 are arranged on both sides of the pouring groove 261, and a heating net 2631 is arranged inside the heating block 263, and the two ends of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com