Pressure water tank for water conservancy project drainage station

A pressurized water tank and water conservancy engineering technology, applied in water conservancy projects, water conservancy engineering equipment, water conservation, etc., can solve the problems of reduced service life of the pressurized water tank, poor protection performance of the pressurized water tank, poor sealing of the pressurized water tank, etc., to achieve improved sealing, The effect of increasing the sealing effect and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

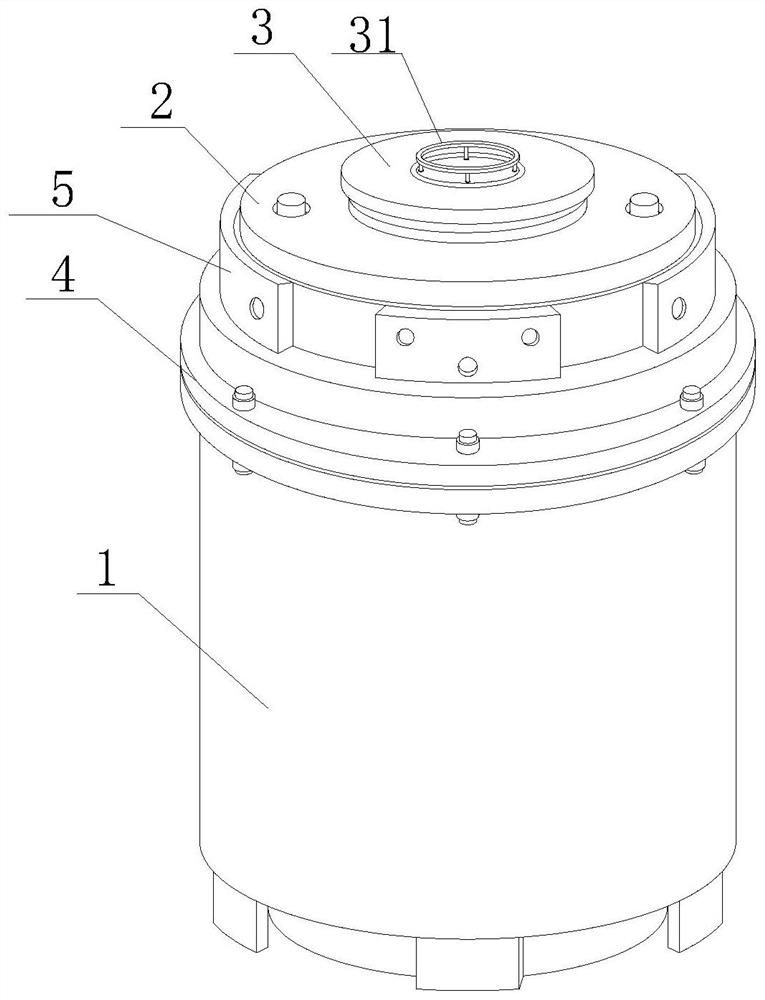

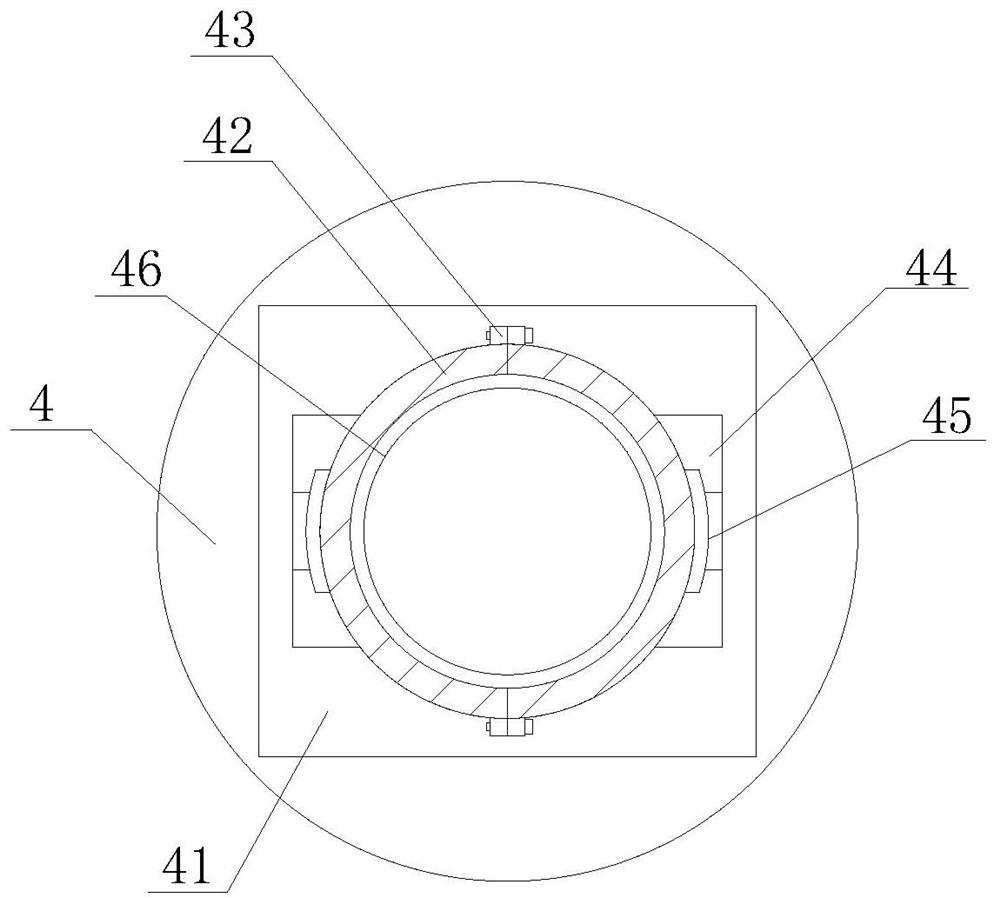

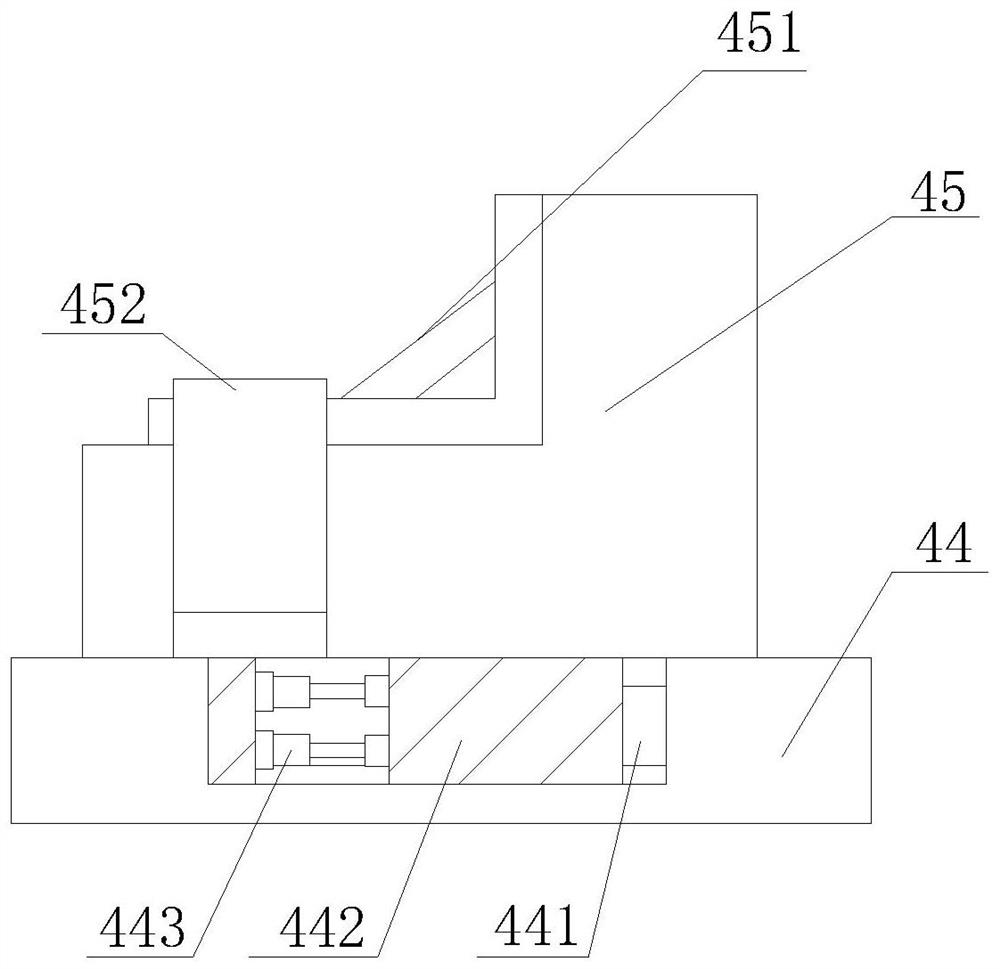

[0042] Such as Figure 1-8 As shown, the present invention provides a pressure water tank for drainage stations of water conservancy projects, comprising a water tank main body 1, a sealing top cover 2, a valve 3 and a sealing flange 4, the top of the water tank main body 1 is threadedly connected with a sealing flange 4, and the sealing method The top of the blue 4 is fixedly installed with a sealing top cover 2, and the top of the sealing top cover 2 is provided with a valve 3, and the top of the valve 3 is fixedly installed with a turret 31, and the outer side of the sealing top cover 2 is fixedly sleeved with a limit ring 51, and the limit The outer side of the ring 51 is provided with a socket groove 52, the inside of the socket groove 52 is movably socketed with a protective baffle 5, the inner side of the sealing flange 4 is fixedly installed with a mounting plate 41, and the inside of the mounting plate 41 is provided with a nozzle, and the mounting plate The top of 41...

Embodiment 2

[0045] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the side of the sealing block 42 is provided with a draw-in groove, and the inside of the draw-in groove is fixedly equipped with a sealing gasket 421, and the side movable sleeve of the sealing gasket 421 A sealing plate 46 is connected, and a moisture-proof plate 461 is fixedly installed on the bottom of the sealing plate 46 , and a sealing film 462 is fixedly installed on the bottom of the moisture-proof plate 461 .

[0046] In this embodiment, the sealing gasket 421 is installed inside the card slot, and the sealing gasket 421 is utilized for its good sealing properties, so that when the sealing plate 46 is installed inside the card slot, the sealing performance of the joint is increased, and then the sealing film 462 cooperates with the moisture-proof plate 461 to further seal the valve port of the water tank main body 1 by utilizing the tigh...

Embodiment 3

[0048] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a push block 53 is fixedly installed on the side of the protective baffle 5, and a pressing pad 532 is fixedly installed on the top of the pushing block 53, and the pressing pad 532 A pressing plate 531 is fixedly installed on the top of the pressing pad 532, and pressing blocks 5321 are arranged on both sides of the inner cavity of the pressing pad 532. A buffer column 5322 is fixedly installed on the inner side of the pressing block 5321, and a pressing column 5311 is arranged inside the pressing plate 531. The bottom of the telescopic bullet column 5312 is provided with a pressing base 5313 fixedly mounted on the bottom of the telescopic bullet column 5312, and an airbag cushion 5314 is fixedly installed inside the pressing base 5313.

[0049] In this embodiment, the protective baffle 5 and the limit ring 51 are sleeved on the outer side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com