Composite copper-imitating color steel plate not prone to rusting

A color steel plate, composite technology, applied in mechanical equipment, vibration suppression adjustment, chemical instruments and methods, etc., can solve the problems of affecting the service life of color steel plates, reducing the decorative effect of color steel plates, and rusting on the surface of color steel plates. The probability of rusting, the function of increasing the rust prevention, the effect of increasing the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

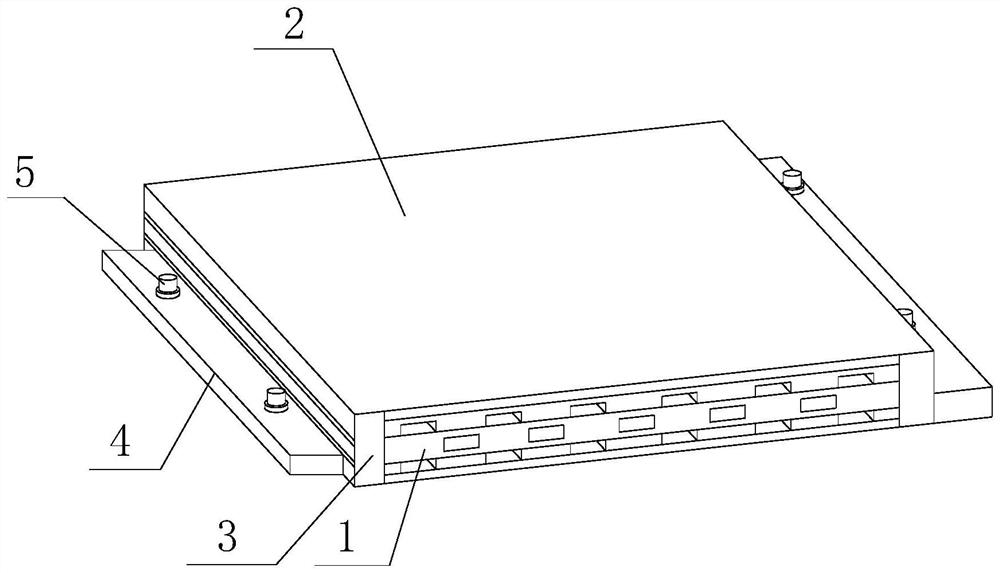

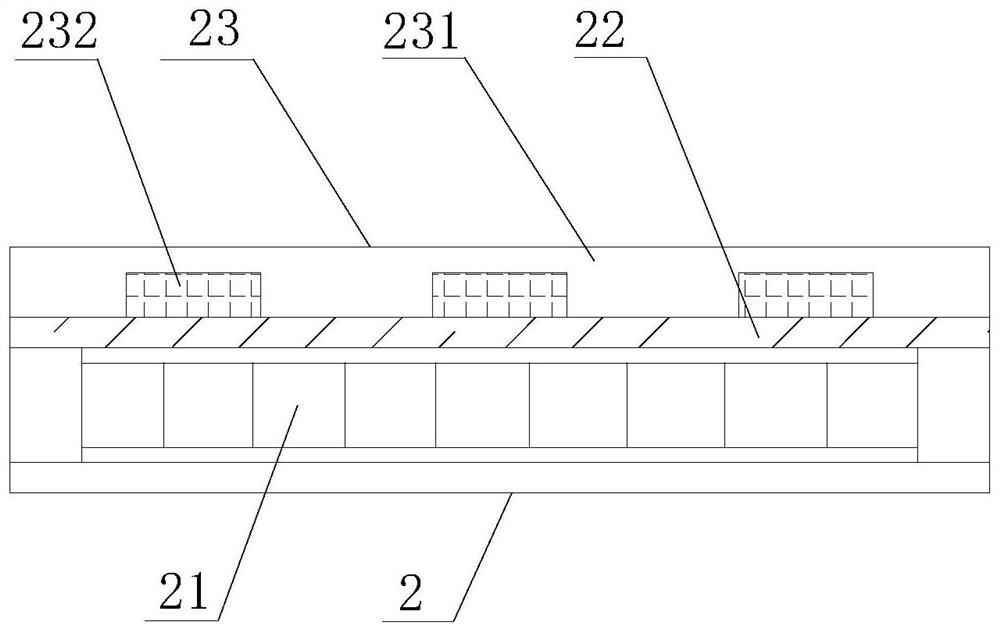

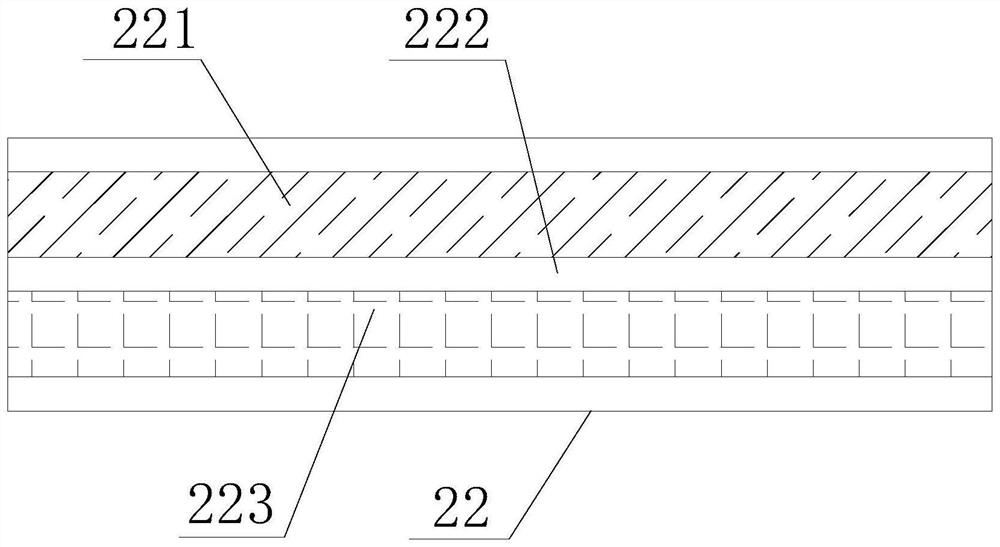

[0035] Such as Figure 1-7 As shown, the present invention provides a composite copper imitation color steel plate that is not easy to rust, including a color steel plate base plate 1, an outer plate layer 2, a connecting block 3 and a connecting plate 4, and an outer plate is fixedly installed on the outer side of the color steel plate base plate 1 Layer 2, the two sides of the outer plate layer 2 are fixedly installed with the connecting block 3, the side of the connecting block 3 is fixedly installed with the connecting plate 4, the inside of the connecting plate 4 is provided with the connecting column 5, and the top of the outer plate layer 2 is fixedly installed with a protective layer 23, the surface of the protective layer 23 is fixedly installed with a transparent antirust film 231, the inside of the protective layer 23 is fixedly installed with a fixed block 232, the bottom of the protective layer 23 is fixedly installed with an antirust layer 22, and the bottom of th...

Embodiment 2

[0038] Such as Figure 1-7As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, a buffer layer 13 is fixedly installed at both ends of the color steel plate substrate 1, and an extrusion pad 12 is arranged inside the buffer layer 13, and the extrusion pad The bottom of 12 is fixedly installed with buffer pad 11, and the inside of buffer pad 11 is fixedly installed with extruding column 111, and the bottom of extruding column 111 is fixedly installed with elastic pressing block 113, and the bottom of elastic pressing block 113 is fixedly installed with pressing pad 16, pressing pad The bottom of 16 is fixedly installed on the outer surface of the color steel plate substrate 1, the middle part of the extruding column 111 is fixedly sleeved with a rebound pad 17, the bottom of the pressing column 112 is movably sleeved with a buffer ring 114, and the bottom of the pressing column 112 is fixed. An extrusion block 115 is installed, an...

Embodiment 3

[0041] like Figure 1-7 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the pressing column 112 is fixedly installed on the top of the pressing column 111, and the outer surface of the pressing column 112 is fixedly equipped with friction particles 1121, Both sides of the buffer ring 114 are fixedly installed on both sides of the inner cavity of the extrusion column 111. The inner cavity of the buffer ring 114 is provided with a friction column 1141, and the surface of the friction column 1141 is provided with a friction hole 1142. The side of the particle 1121.

[0042] In this embodiment, the pressing column 111 is forced to squeeze, and the pressing column 112 is driven to squeeze and move inside the buffer ring 114, and then the pressing column 112 is pressed down to drive the friction particles 1121 rubs inside the friction hole 1142, using the friction force of the contact to achieve the effect of buffering consumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com