A kind of anti-corrosion and anti-rust concrete and its application

A technology for concrete and concrete preservatives, which is applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve problems such as structural damage, affect the normal use of concrete structures, and lose structural durability, and achieve the effect of improving rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

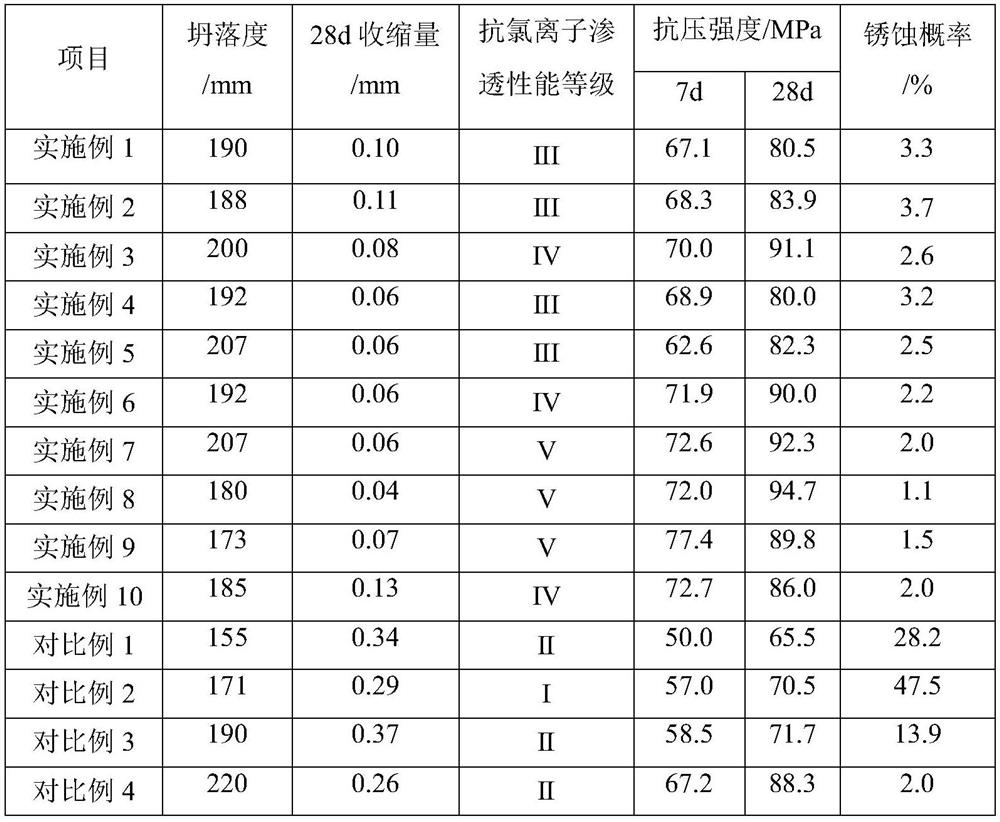

Examples

Embodiment 1

[0030] An anti-corrosion and anti-rust concrete, including the following raw material components in parts by weight: 300kg of P.O42.5 ordinary Portland cement, 680kg of medium sand, 980kg of gravel, 35kg of I-level wind separation fly ash, 50kg of S95 mineral powder, ZQ -3 8kg of waterproof pumping agent, 8kg of FSS-7A anti-sulfate preservative, 8kg of FS-7B high-efficiency rust inhibitor and 150kg of water, of which the sand rate is 41.0%, and the water-binder ratio is 0.41.

Embodiment 2

[0032] An anti-corrosion and anti-rust concrete, including the following raw material components in parts by weight: 300kg of P.O42.5 ordinary Portland cement, 680kg of medium sand, 980kg of gravel, 50kg of I-level wind separation fly ash, 35kg of S95 mineral powder, ZQ -3 8kg of waterproof pumping agent, 8kg of FSS-7A anti-sulfate preservative, 8kg of FS-7B high-efficiency rust inhibitor and 150kg of water, of which the sand rate is 41.0%, and the water-binder ratio is 0.41.

Embodiment 3

[0034] An anti-corrosion and anti-rust concrete, including the following raw material components in parts by weight: 300kg of P.O42.5 ordinary Portland cement, 680kg of medium sand, 980kg of gravel, 35kg of I-level winnowing fly ash, 35kg of S95 mineral powder, ZQ -3 8kg of waterproof pumping agent, 8kg of FSS-7A anti-sulfate preservative, 8kg of FS-7B high-efficiency rust inhibitor and 150kg of water, of which the sand rate is 41.0%, and the water-binder ratio is 0.41.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com