Rapid detection die for automotive trim finished product

A technology for detecting molds and automotive interiors, applied to household appliances, other household appliances, household components, etc., can solve the problems of cumbersome connections, increased difficulty of disassembly, and increased manual labor, so as to improve safety performance, increase work efficiency, The effect of increasing cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

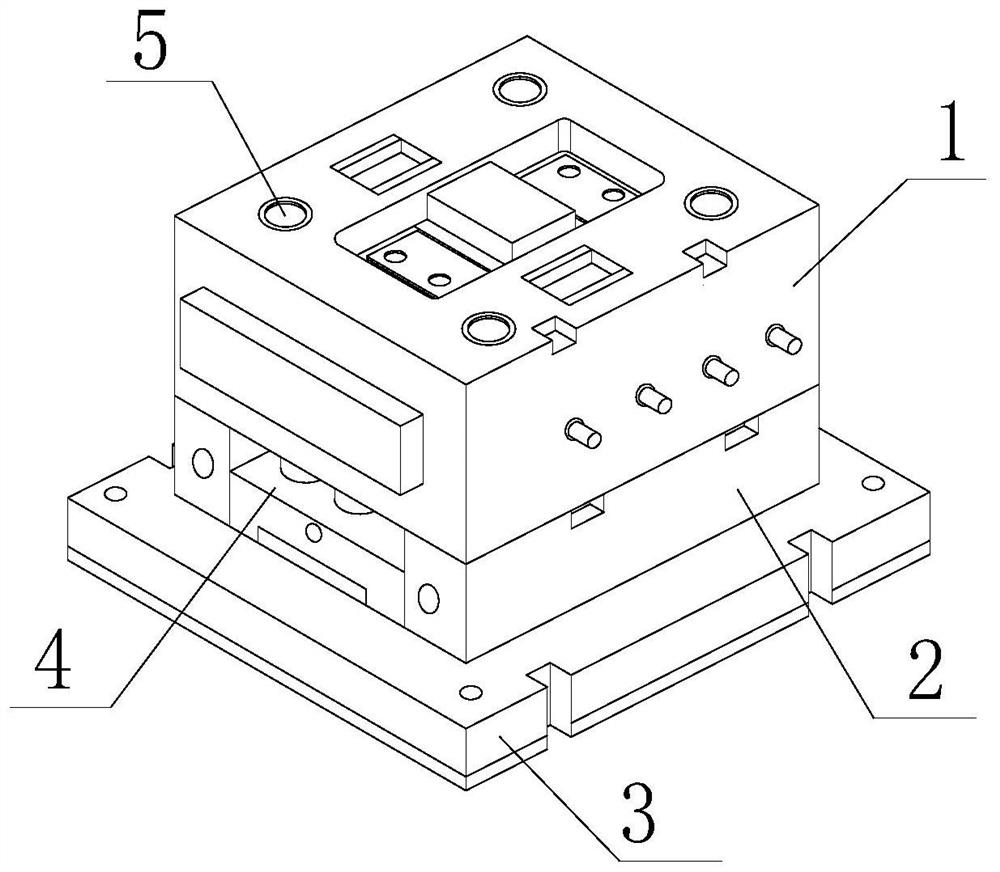

[0035] as Figure 1-10 As shown in the figure, the invention provides a rapid detection mold for finished automotive interior products, including an upper mold 1, a lower mold 2, a fixed base 3, a detection mold 4 and a reinforcing column 5. The interior of the upper mold 1 is provided with a reinforcing column 5, the bottom of the upper mold 1 is provided with a lower mold 2, both sides of the lower mold 2 are provided with connecting grooves, the interior of the connecting groove is arranged at the bottom of the reinforcing column 5, and the bottom of the lower mold 2 is fixedly provided with a fixed base 3, The inner part of the lower die 2 is provided with a detection die 4, the inner part of the detection die 4 is fixedly installed with a die groove, the inner cavity of the die groove is provided with a detection rod 401, both ends of the detection rod 401 are arranged on both sides of the die groove, the inner part of the die groove is provided with a moving groove 402, and t...

Embodiment 2

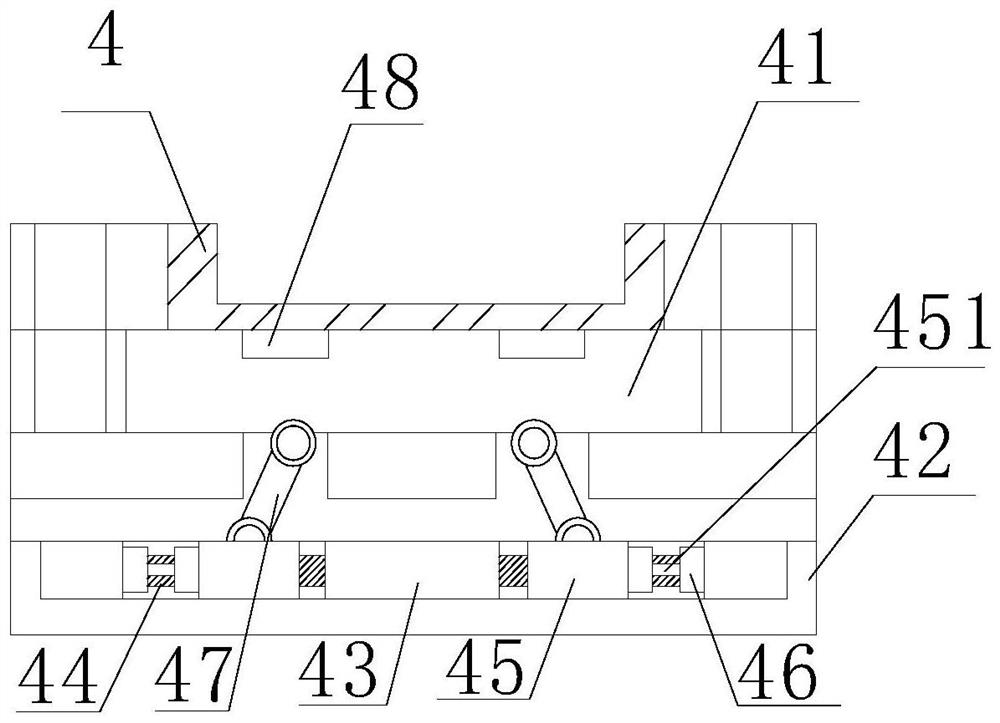

[0038] as Figure 1-10 As shown in the figure, on the basis of embodiment 1, the invention provides a technical scheme: preferably, the ejection mechanism comprises an ejection plate 41, the top of the ejection plate 41 is fixedly equipped with a buffer 48, and the bottom of the ejection plate 41 is provided with an ejection plate 42.

[0039] The inner part of the push out plate 42 is fixedly equipped with a limit block 43, both sides of the limit block 43 are fixedly equipped with a sliding column 44, the outer side of the sliding column 44 is provided with a moving block 45, the side of the moving block 45 is fixedly connected with a telescopic column 451, the other end of the telescopic column 451 is arranged on the inner side of the push out plate 42, the top of the moving block 45 is provided with an ejector rod 47, and the top of the ejector rod 47 is movably installed at the bottom of the ejector plate 41.

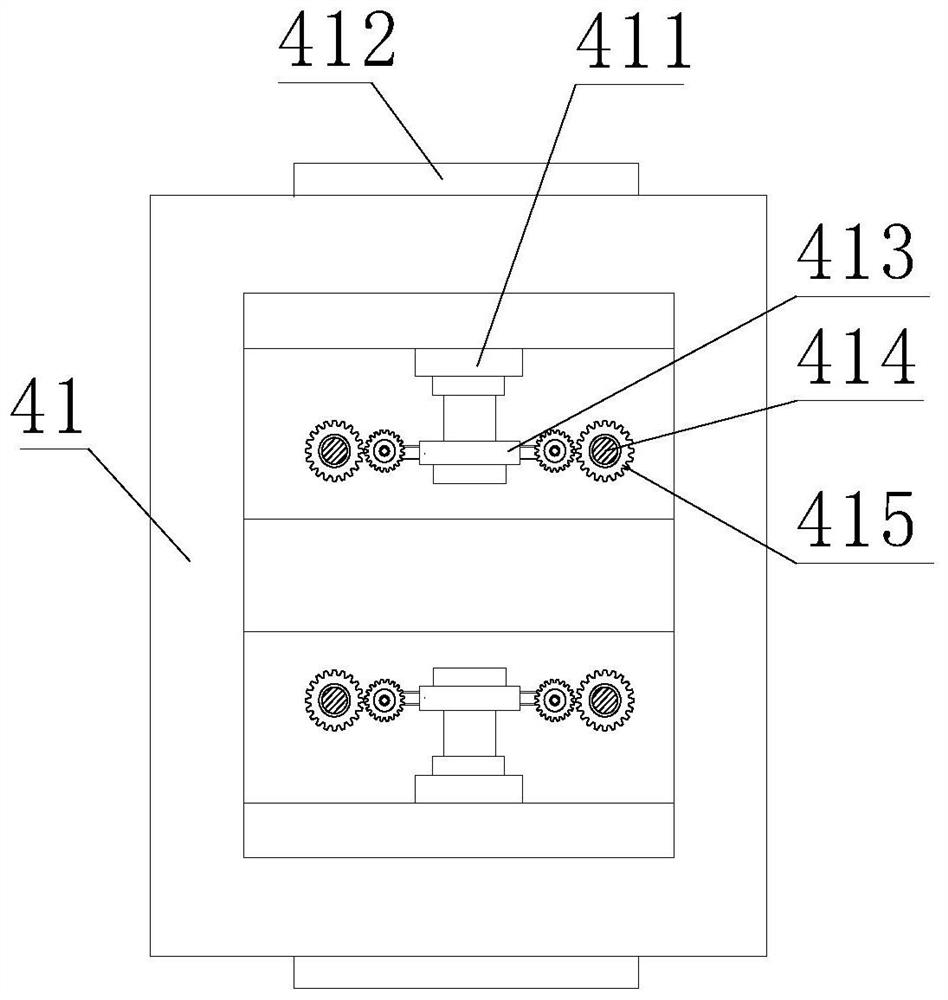

[0040] Both sides of the inner cavity of the ejector plate 41 are ...

Embodiment 3

[0044] as Figure 1-10 As shown in the figure, on the basis of embodiment 1, the invention provides a technical scheme: preferably, a pressing pad 481 is arranged inside the buffer pad 48, an elastic pad 482 is fixedly installed inside the pressing pad 481, an extrusion block 483 is arranged inside the elastic pad 482, a compression column 484 is arranged inside the extrusion block 483, fixed blocks are arranged at both ends of the compression column 484, and extrusion columns 485 are arranged on both sides of the fixed block, The other end of the extrusion column 485 is arranged inside the elastic pad 482.

[0045] In this embodiment, when the cushion 48 is pressed by force, the pressing pad 481 compresses the elastic pad 482 so that the pressing block 483 presses the compression column 484 on the inner side with each other, and then when the fixed block moves down, the pressing column 485 is pushed to squeeze the pressing blocks 483 on both sides, and the rebound force of the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com