Device and method for positioning overall frame of airplane

A technology of positioning device and integral frame, applied in aircraft assembly and other directions, can solve the problems of inability to meet the needs of production line assembly, inaccurate positioning of the frame body, and reduce production efficiency, and achieve the effect of improving assembly quality, simplifying structure, and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

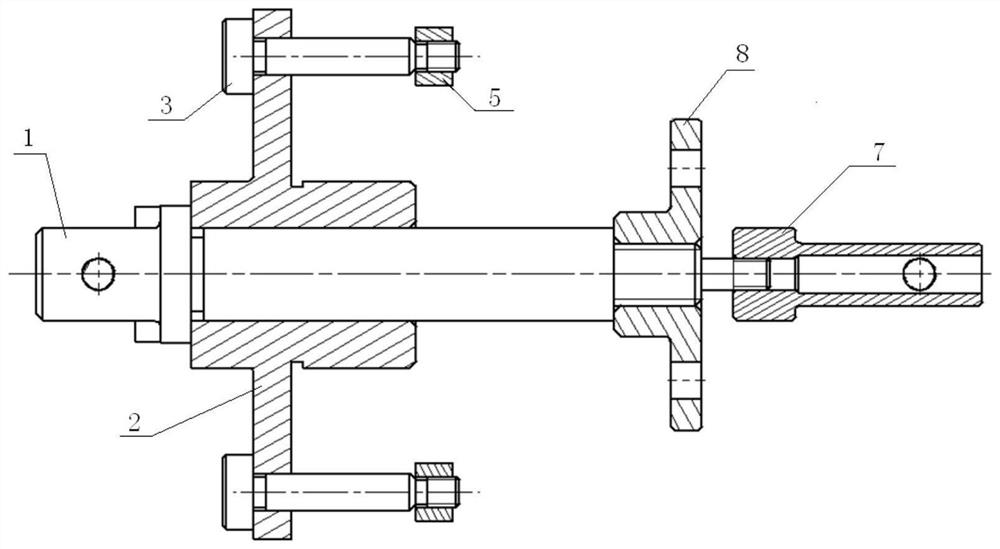

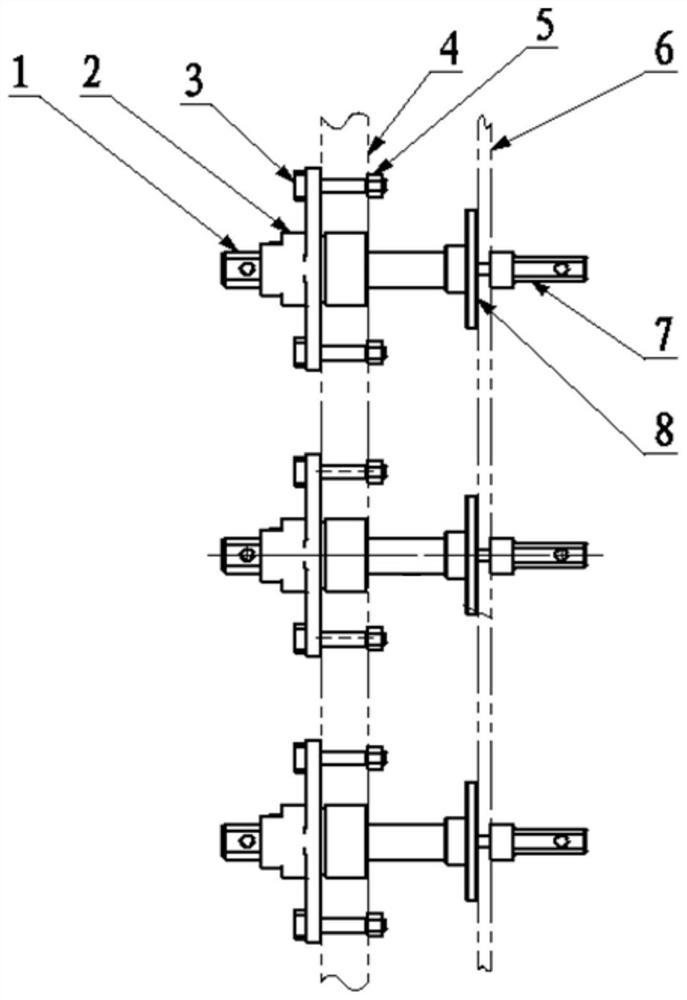

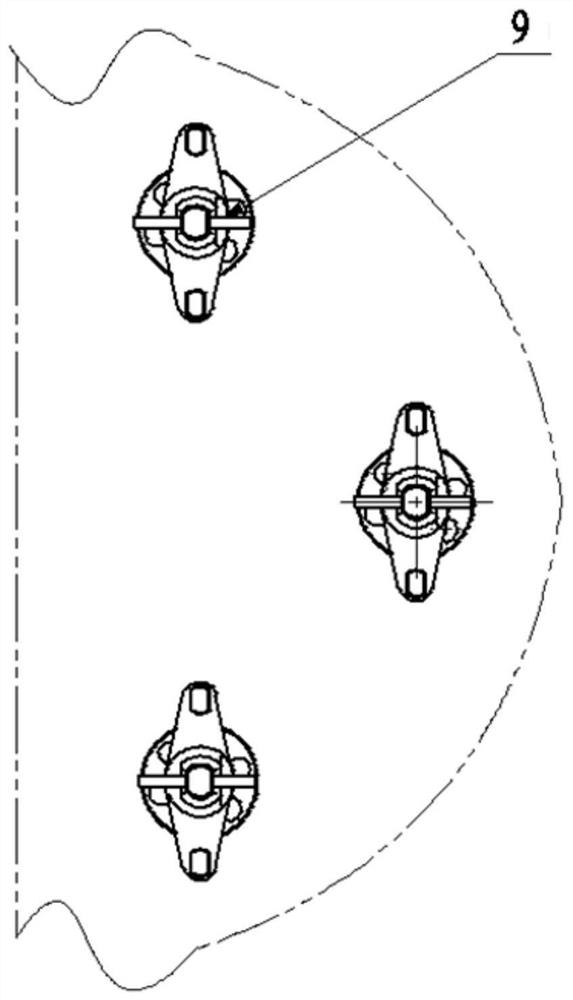

[0022] Such as figure 1 As shown; the proposed aircraft integral frame positioning device, the device includes a slide 2, a refining bolt 3, a nut 5, a compression nut 7, a flange 8, a slide pin 1; wherein the slide 2 is purified by The bolt 3 and the nut 5 are connected to the mounting base 4, and then the slide 1 passes through the slide 2, and then the flange 8 is threaded over and the slip pin 1 is connected, and finally the special pressing nut 7 is pressed into the overall frame 6, Make the overall box to close the flange 8, in order to achieve self-locking between the slide 2 and the slide pin, the slider 2 end is provided with a circular arc-shaped boss, and a card slot is opened on the boss; There is a ring boss on the pin 1. There is a slit on the annular boss, and the cutting shape is approximately an outer shape, and the slide pin is rotated. When the annular boss is screwed into the card slot of the slide 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com