Automatic sampler

A technology of automatic sampling and sampling device, which is applied in the direction of instruments and analytical materials, can solve the problems of unstable movement and easy shaking of automatic sample injectors, and achieve the effects of strong anti-interference ability, improving ability and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

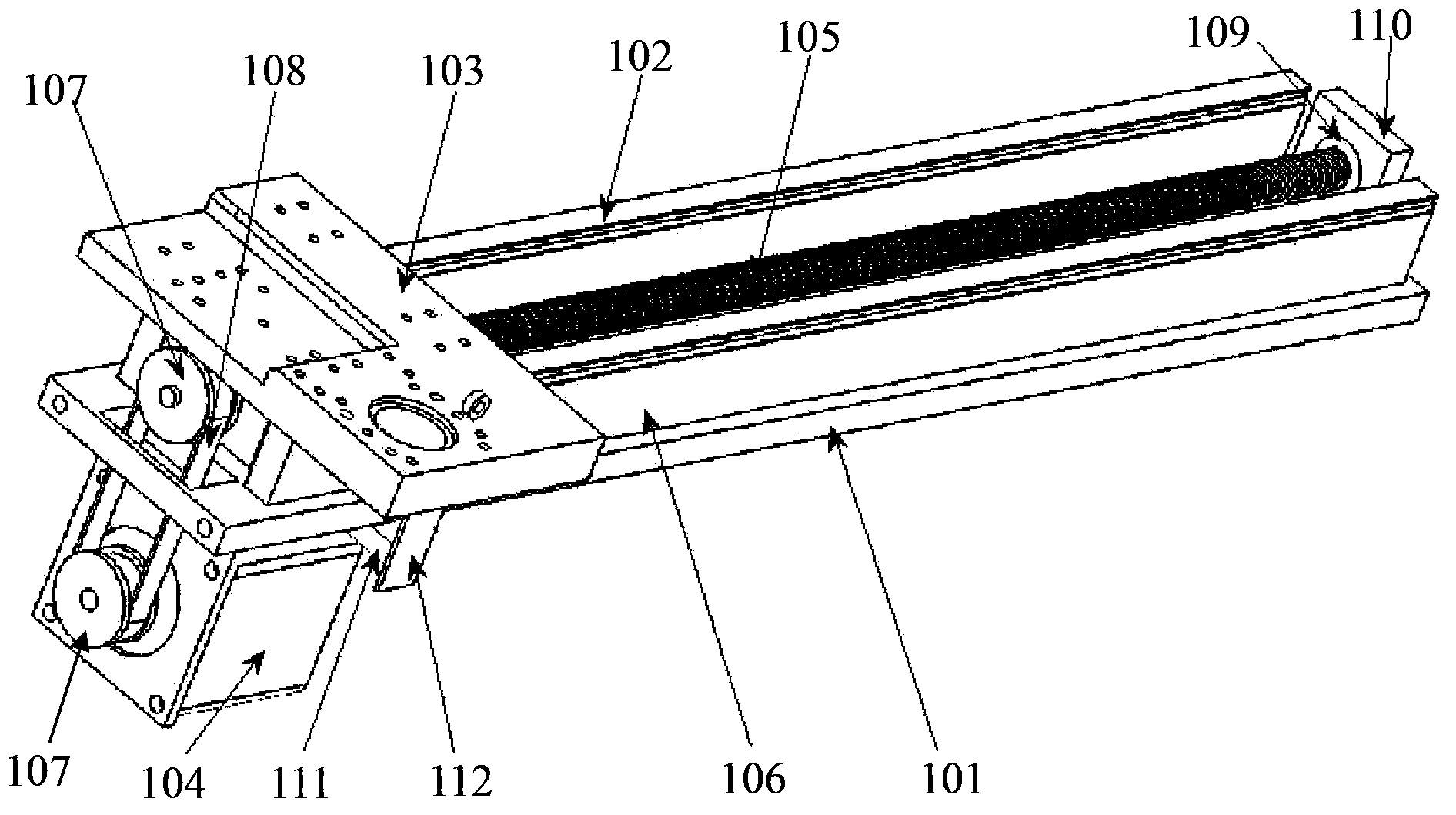

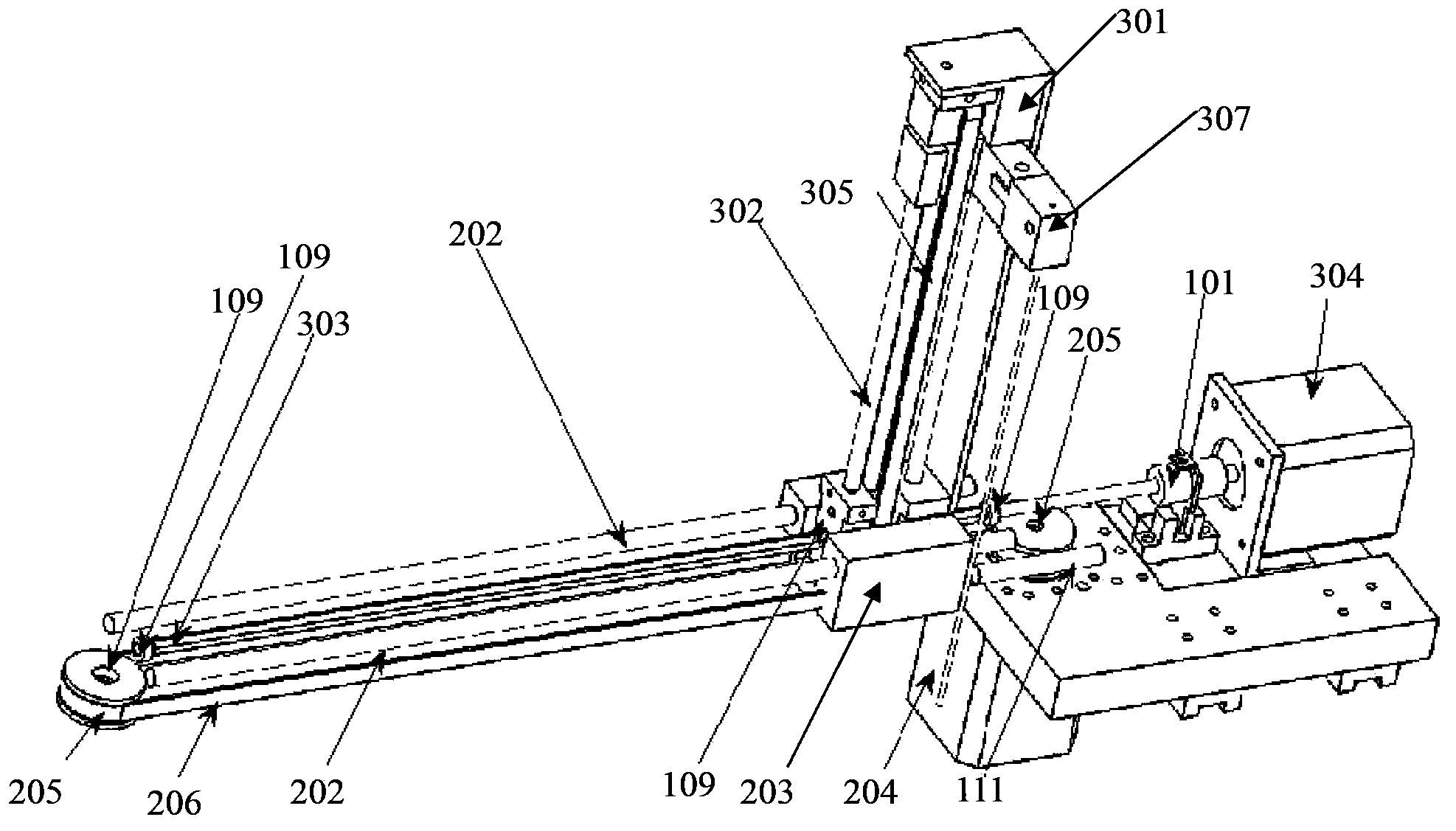

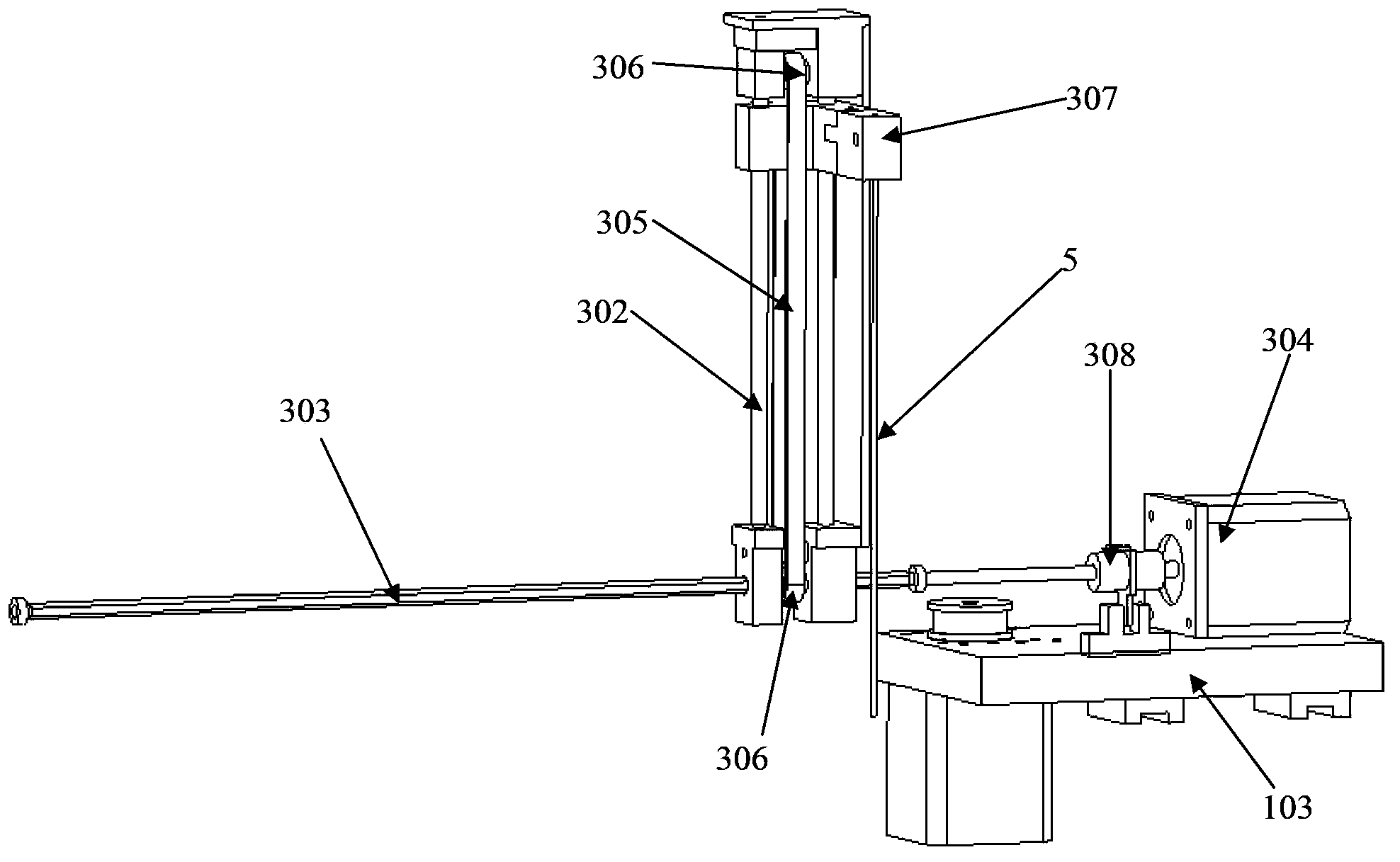

[0026] Such as Figure 1-Figure 5 As shown, the autosampler of the present invention includes an X-axis motion assembly, a Y-axis motion assembly, a Z-axis motion assembly, and a sampling device 5. For the convenience of description, the horizontal direction is designated as the X-axis, the vertical direction is the Y-axis, and the vertical direction is the Z-axis .

[0027] Among them, such as figure 1 As shown, the X-axis motion assembly includes a bottom plate 101 , a first guide rail 102 , a first connecting plate 103 , a first motor 104 , a first lead screw 105 , and two first synchronous wheels 107 . The base plate 101 functions as a fixed support, and the first guide rail 102 and the first motor 104 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com