Optical cable easy to peel

A stripping, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of wasting time, easy to damage optical fibers, etc., to avoid pollution and facilitate wiring and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0015] 【Example】

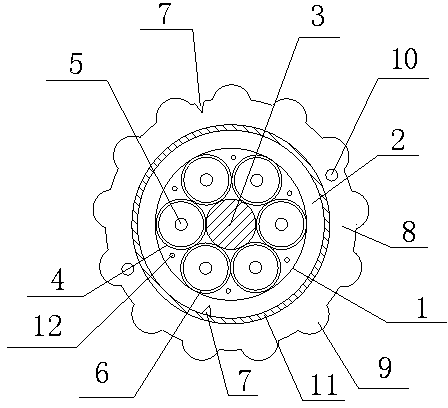

[0016] like figure 1 As shown, the easy-to-peel optical cable includes a cable core 1 and an inner sheath 2 wrapping the cable core 1. The cable core 1 includes a strengthening member 3 and an optical fiber unit 4 arranged around the strengthening member 3. The optical fiber unit The number of 4 is 6, the optical fiber unit 4 includes the optical fiber 5 and the loose tube 6 wrapping the optical fiber 5, the inner sheath 2 wraps the outer sheath 8, and the outer walls of the inner sheath 2 and the outer sheath 8 are An easy-to-tear opening 7 is provided along the extending direction of the optical cable, and the outside of the outer sheath 8 is provided with embossed lines 9, the cross section of which is semicircular, and its direction is consistent with the extending direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com