A battery module combination structure suitable for quick-change battery boxes of pure electric buses

A pure electric bus and battery module technology, which is applied to battery pack parts, non-aqueous electrolyte batteries, power system fuel cells, etc., can solve the problems that batteries cannot be installed, and achieve self-dissipation, weight reduction, and excellent insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

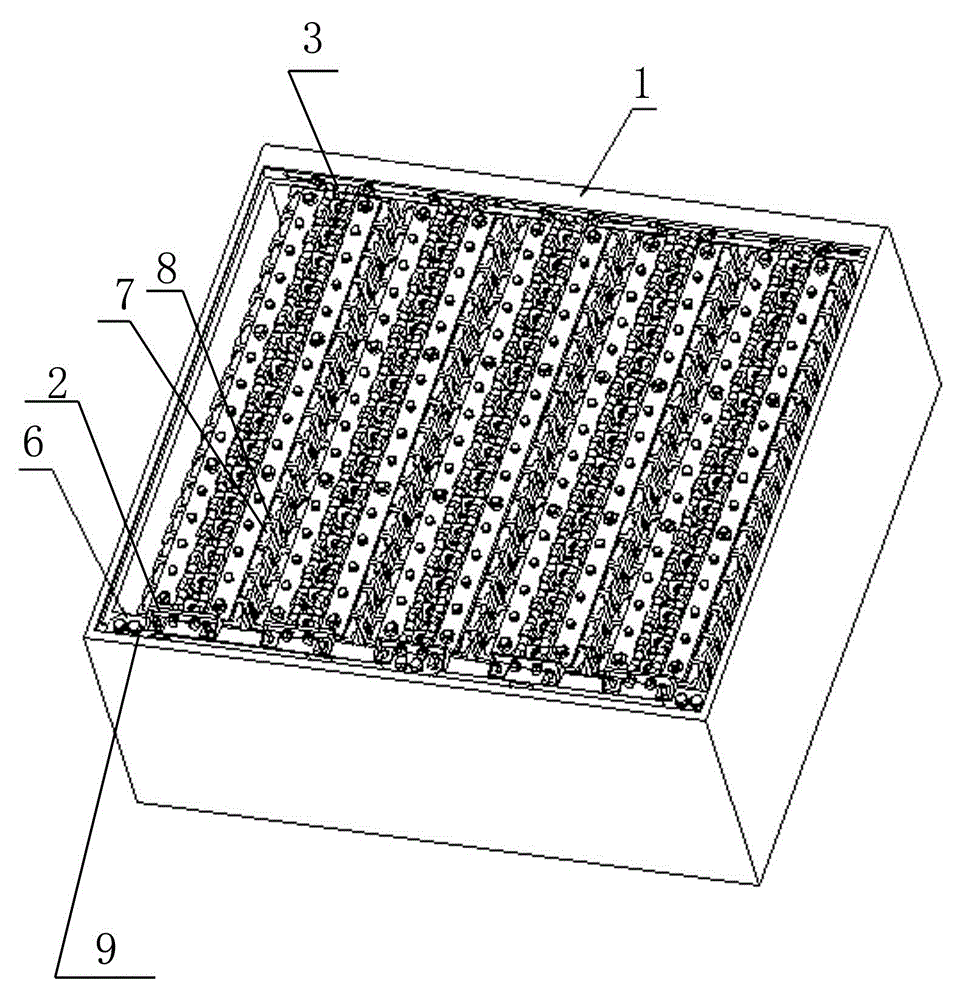

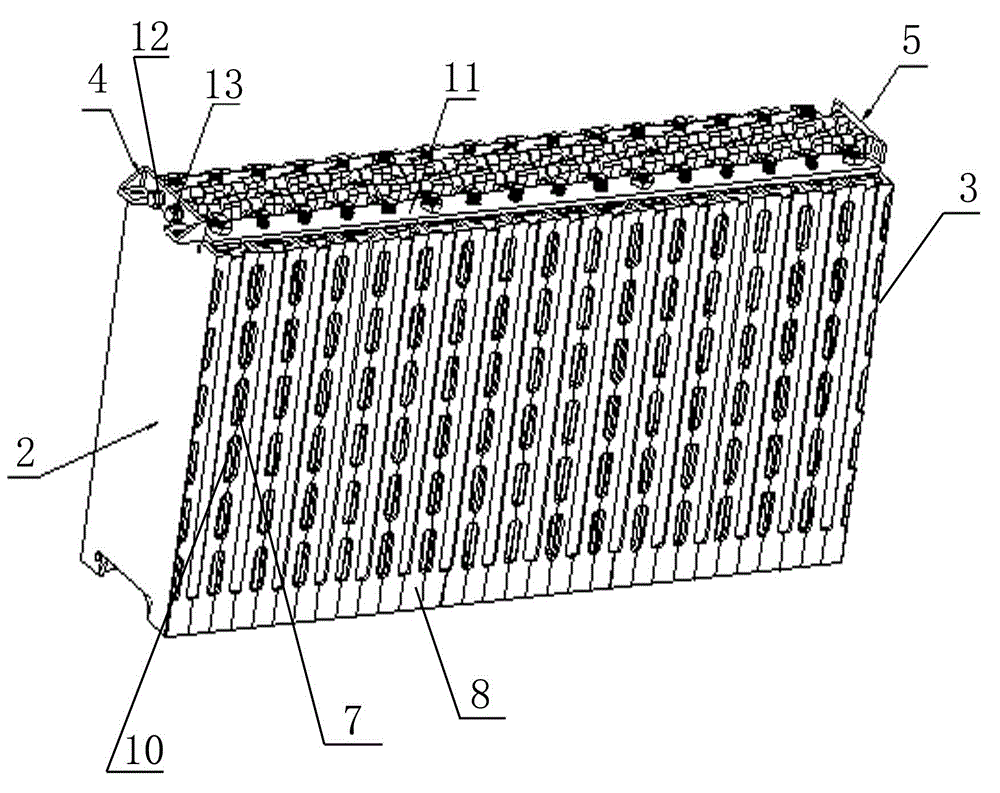

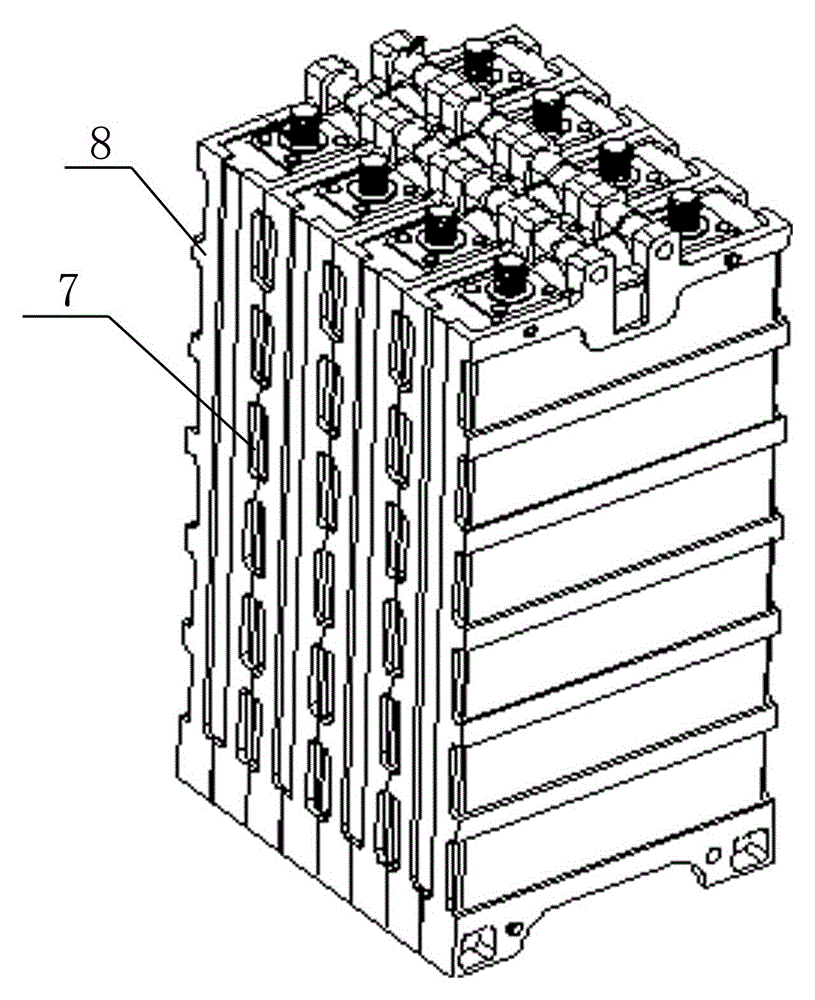

[0011] Embodiment one, in figure 1 , figure 2 and image 3 Among them, the present invention provides a battery module combination structure suitable for the quick-change battery box of pure electric passenger cars, which is provided with five battery modules and the quick-change battery box 1, and the five battery modules are installed in the quick-change battery box 1. The bottom surface of the replacement battery box 1 is pasted with an insulating silicon rubber plate. The insulating silicon rubber plate is placed on the bottom of the battery module and corresponds to the battery module. An insulating plate I2 and an insulating plate II3 are respectively provided on the two outer sides of each battery module. The upper part of the plate I2 is provided with a pressing block I4, the upper part of the insulating plate II3 is provided with a pressing block II5, and the connecting plate 6 is provided on one side of the quick-change battery box 1, and each battery module passes...

Embodiment 2

[0012] Embodiment 2, the present invention provides a battery module combination structure applicable to the quick-change battery box of pure electric passenger cars, which is provided with five battery modules and the quick-change battery box 1, and the five battery modules are installed in the quick-change battery box 1 , the bottom surface of the quick-change battery box 1 is pasted with an insulating silicone rubber plate, which is placed on the bottom of the battery module and corresponds to the battery module, and an insulating plate I2 and an insulating plate II3 are respectively provided on the two outer sides of each battery module. A pressure block I4 is provided on the upper part of the insulating plate I2, a pressure block II5 is provided on the upper part of the insulating plate II3, and a connection plate 6 is provided on one side of the quick-change battery box 1, and each battery module is connected to the connection plate through the pressure block II5 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com