Connector with high connecting safety

A safety and connector technology, which is applied to the parts, connections, and protective grounding/shielding devices of connecting devices, etc., can solve the problems of cable disconnection, easy to fall off, easy to cause safety accidents, etc., to avoid safety Accident, interference prevention, effect of avoiding water ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

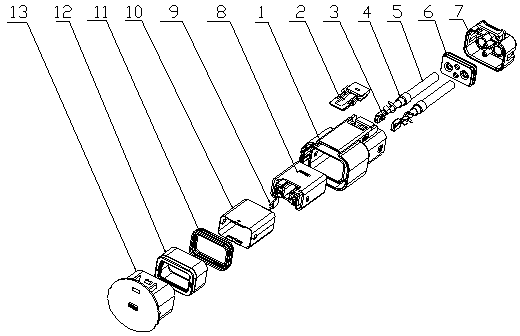

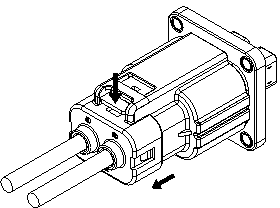

[0022] Such as figure 1 , figure 2 A double-core connector with high connection safety is shown, including a plug and a socket. The plug includes a plug shell 1, and a double-core plug inner shell 8 is arranged inside the plug shell 1, and a double-core plug inner shell 8 is arranged inside the plug inner shell 8. There are male signal terminals 9 and female pins 3, the male signal terminals 9 are in contact with the female pins 3, the female pins 3 are connected to the wires 5 through the pressure tube 4, and a front gland 12 is provided at the front end of the plug inner shell 8, The rear end of the plug inner shell 8 is provided with a tail cap 7, and the electric wire 5 passes through the tail cap 7; the socket includes a socket base 15, and a socket inner shell 16 is arranged in the socket base 15, and the socket inner shell 16 There are female signal terminals 18 and male pins 20 inside, the female signal terminals 18 are in contact with the male pins 20, the male pins...

Embodiment 2

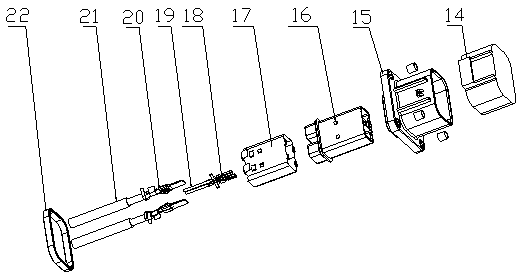

[0025] Such as Figure 8 and Figure 9 A three-core connector with high connection safety is shown, including a plug and a socket. The plug includes a plug shell 1, and a three-core plug inner shell 8 is arranged inside the plug shell 1, and a three-core plug inner shell 8 is arranged inside the plug inner shell 8. The female pin 3, the female pin 3 is connected to the electric wire 5 through the pressure tube 4, a front gland 12 is provided at the front end of the plug inner shell 16, and a tail cap 7 is provided at the rear end of the plug inner shell 8, and the electric wire 5 Through the tail cap 7; the socket includes a socket base 15, and a socket inner shell 16 is arranged in the socket base 15, and a male pin 20 is arranged in the socket inner shell 16, and the male pin 20 is connected with an electric wire 21, The plug shell 1 and the socket base 15 are provided with a locking device 23, and the locking device 23 is provided with a locking member 2; the plug inner sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com