Building outer glass curtain wall splicing device

A technology of splicing device and outer glass, applied in the direction of lifting device, lifting equipment safety device, manipulator, etc., can solve the problems of not considering glass lifting and picking, manual installation is time-consuming and laborious, low degree of automation, etc., and achieves fast and convenient construction. , The effect of improving work efficiency and improving work automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

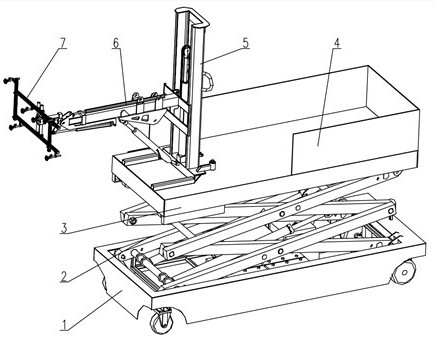

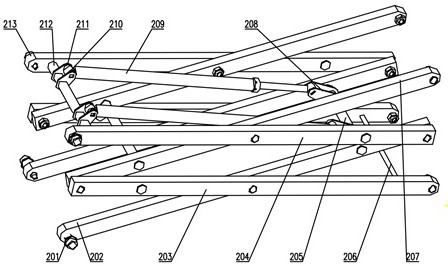

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 A glass curtain wall splicing device outside a building is shown. The walking trolley 1 is the installation body of the whole device, the elevator 2 is fixedly installed on the top of the walking trolley 1, the operating platform 3 is fixedly installed on the top of the elevator 2, the guardrail 4 is fixedly installed on the top of the operating platform 3, and the lifting device 5 is fixedly installed on the On the top of the operating platform 3 , the manipulator 6 is fixedly installed on the lifting device 5 , and the glass suction device 7 is fixedly installed on the manipulator 6 .

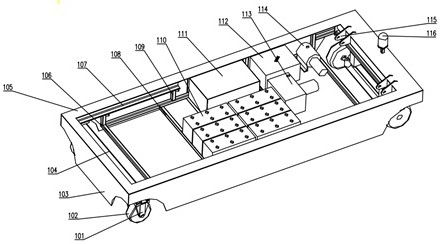

[0027] The specific structure of walking trolley 1 is as follows: figure 2 As shown, there are four wheel bases 101, which are fixedly installed on the bottom of the front and rear end beams 104, and there are four running wheels 102, which are installed on the four end beams 104 through pin rotation, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com