Building pile foundation

The invention relates to a technology for building piles and pile foundations, which is applied to building pile foundations. field, to achieve the effect of improving efficiency, accelerating the speed of digging down, and increasing the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

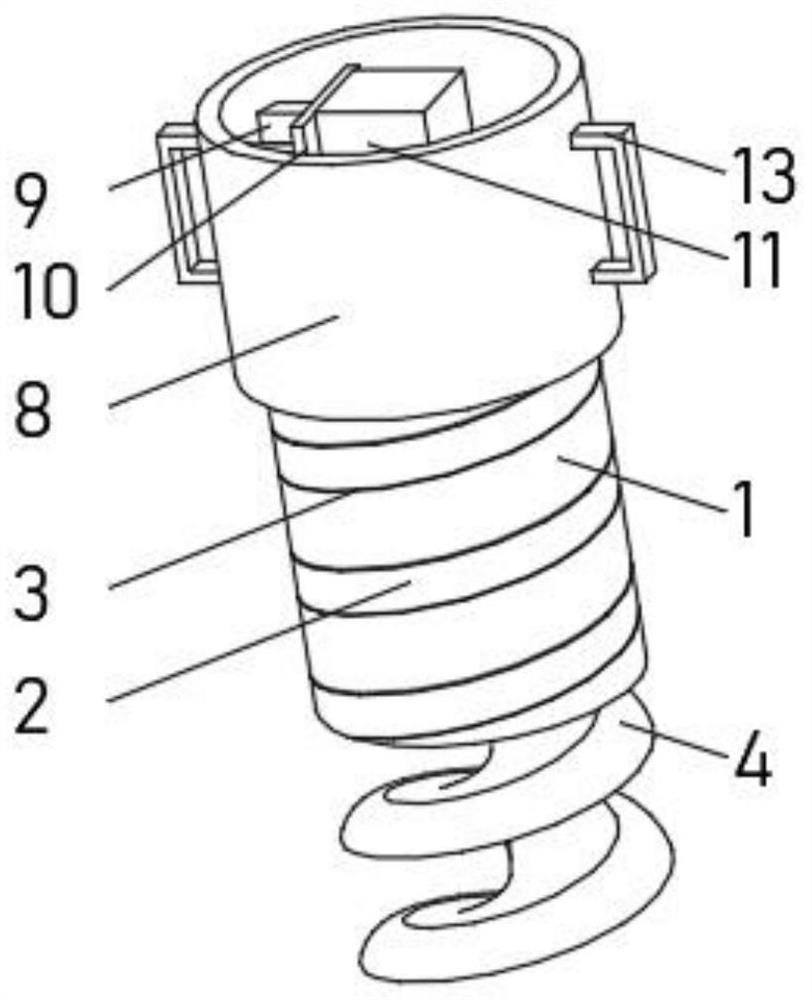

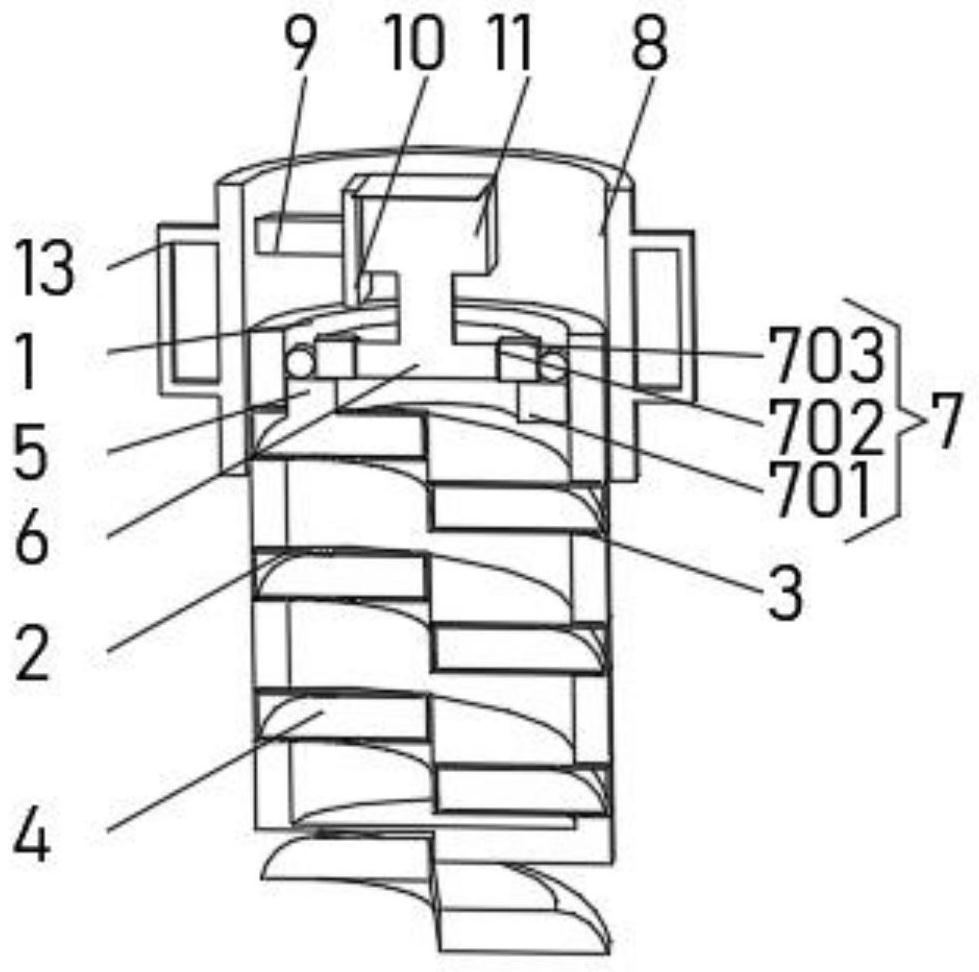

[0028] see Figure 1-2 , the present invention provides a technical solution: a construction pile foundation, comprising a pile foundation frame 1, a spiral frame 2 is installed on the inner wall of the pile foundation frame 1, the spiral frame 2 runs through the pile foundation frame 1, and the pile foundation frame 1 The outside of the frame 1 is provided with an installation groove 3 that is compatible with the spiral outer frame 2. Both ends of the spiral outer frame 2 are designed with openings. Both ends extend to the outside of the spiral outer frame 2, the top end of the rotary soil knife 4 is fixedly connected with a positioning disc 6 through a connecting block 5, and the inner wall of the pile foundation outer frame 1 is located below the positioning disc 6 and a positioning device 7 is installed One end of the bottom of the rotary soil knife 4 extends to the outside of the pile foundation frame 1, and the top end of the pile foundation frame 1 is provided with a po...

Embodiment 2

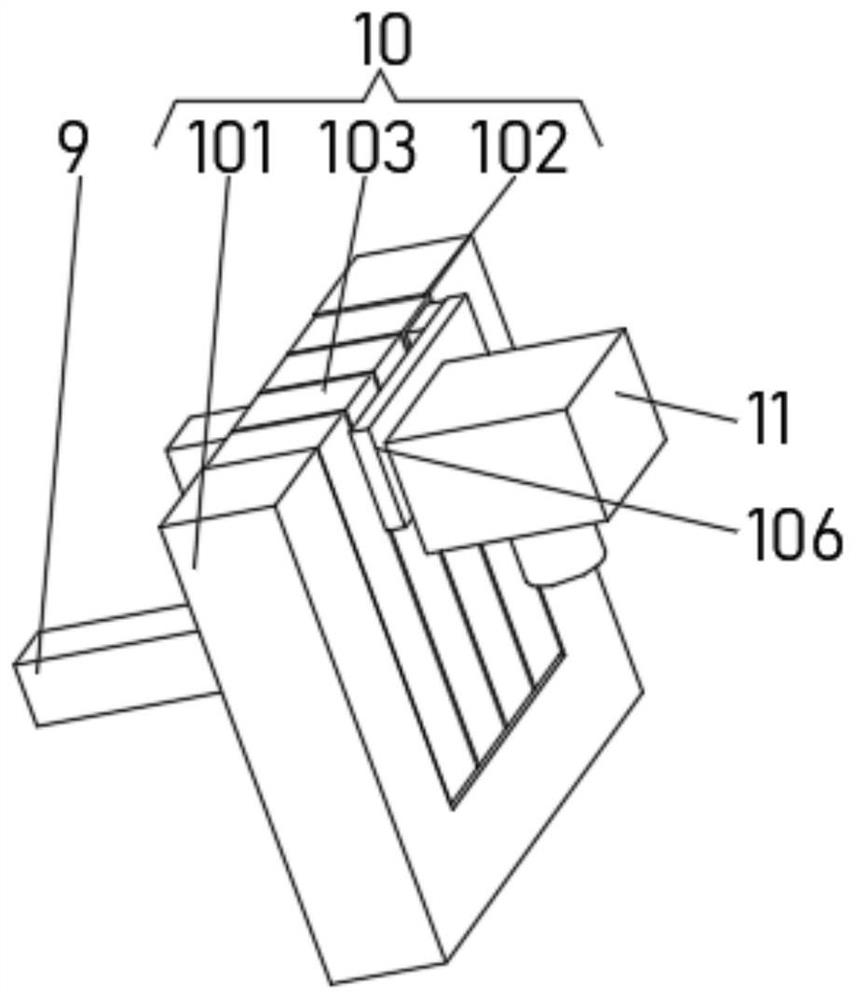

[0033] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, the limiting plate 10 includes a vertical plate 101, one side of the vertical plate 101 is fixedly connected with the connecting rod 9, and a track is provided in the middle position of one side of the vertical plate 101 The groove 102 and the two sides of the track groove 102 are evenly equipped with lifting plates 103 , the lifting plates 103 are slidably connected, and the lifting plate 103 is slidably connected with the inner wall of the track groove 102 .

[0034] One side of the track groove 102 and the lifting plate 103 is provided with a longitudinal chute 104, and one end of the bottom of one side of the lifting plate 103 is fixedly connected with a slider 105, and one end of the slider 105 extends to the inside of the longitudinal chute 104 and is connected with the longitudinal chute. The inner wall of the groove 104 is slidingly connected.

[0035] The lifti...

Embodiment 3

[0038] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a filling device 12 is evenly installed on the top of the spiral outer frame 2, and the filling device 12 includes a filling hole 121, and the filling hole 121 is opened on the top of the spiral outer frame 2, One side of the inner wall of the filling groove 121 is rotatably connected with an isolation plate 122, the bottom of the isolation plate 122 is equipped with a metal block 123, and the bottom of the isolation plate 122 is provided with a metal installation groove suitable for the metal block 123. A magnet block 124 is mounted on the top close to the filling hole 121 , and a magnet installation slot matching the magnet block 124 is opened on the inner top of the spiral outer frame 2 .

[0039] During use, the drilling motor 11 drives the rotary soil cutter 4 to rise along the spiral outer frame 2. When the rotary soil cutter 4 gradually moves to the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com