Automatic printing method of three-dimensional pattern on vehicle body surface

A three-dimensional pattern and inkjet technology, which is applied in the field of personalized body decoration and special vehicle camouflage inkjet printing, to achieve the effect of realistic pattern, uniform printing and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

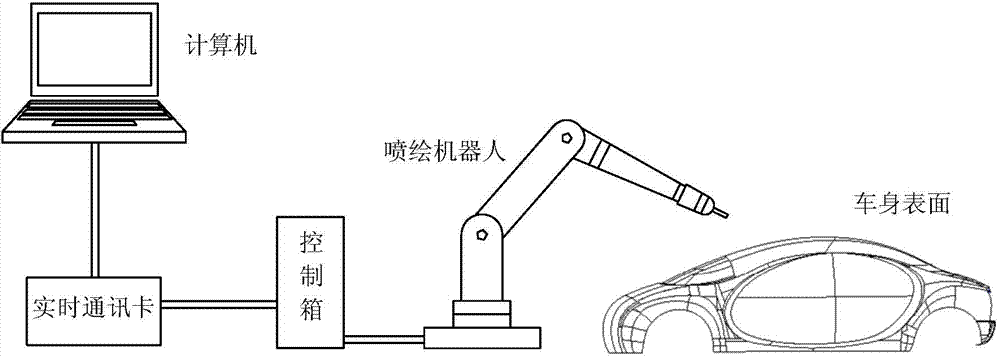

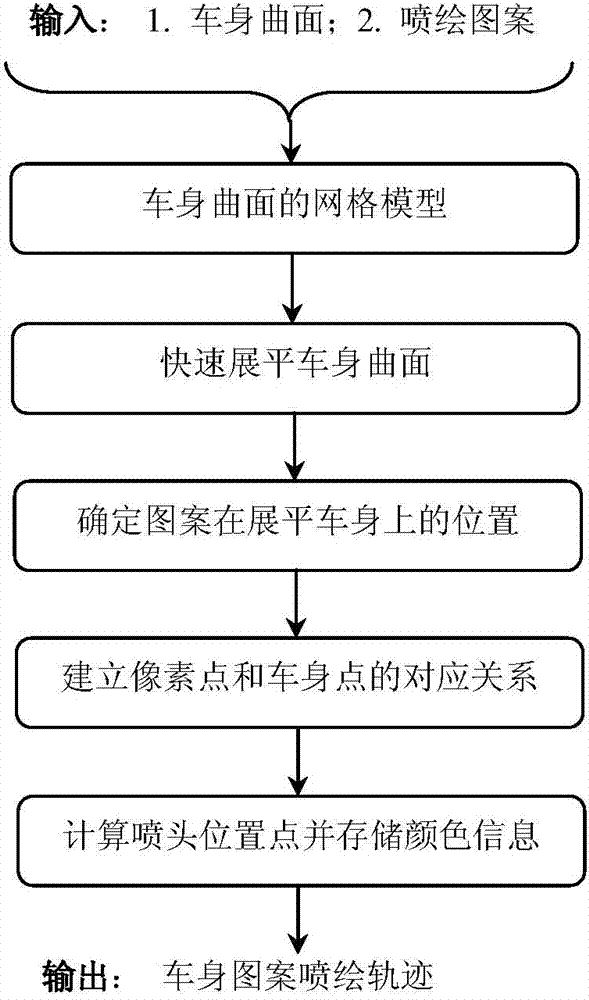

[0024] The specific implementation of the present invention is described in detail with reference to the accompanying drawings and implementation steps. The schematic diagram of the inkjet system is shown in figure 1 shown. The present invention is to generate a motion trajectory capable of driving an inkjet robot for inkjet painting. The flow process of the whole method is as follows: figure 2 shown. The specific implementation process is as follows:

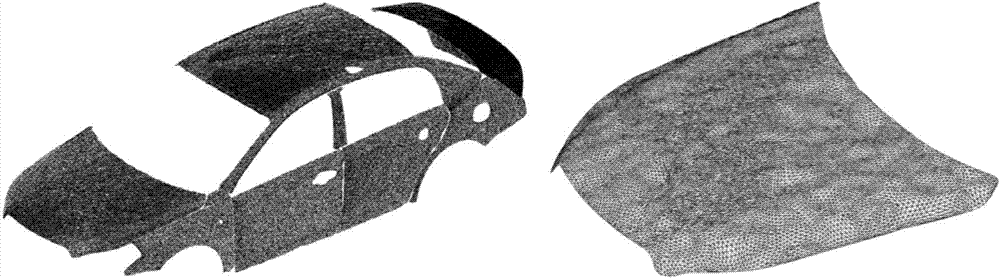

[0025] 1. First, establish the 3D CAD model of the body parts in CAD design software such as UG, CATIA, etc. as the driving model of the entire inkjet system; use the data output function of the CAD design software to output the parametric CAD model as a triangular mesh model, And save it in STL format, such as image 3 shown.

[0026] 2. By simulating the inverse process of the stamping forming of the body panel, the three-dimensional body surface is flattened onto a two-dimensional plane; the basic idea of the method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com