positioning compactor

A technology of compactor and positioning shaft, which is applied in the direction of aircraft assembly, aircraft parts, ground equipment, etc., can solve the problems of inability to meet the requirements of assembly accuracy and positioning, and meet the needs of mutual coordination of assembly accuracy and meet the needs of assembly. Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

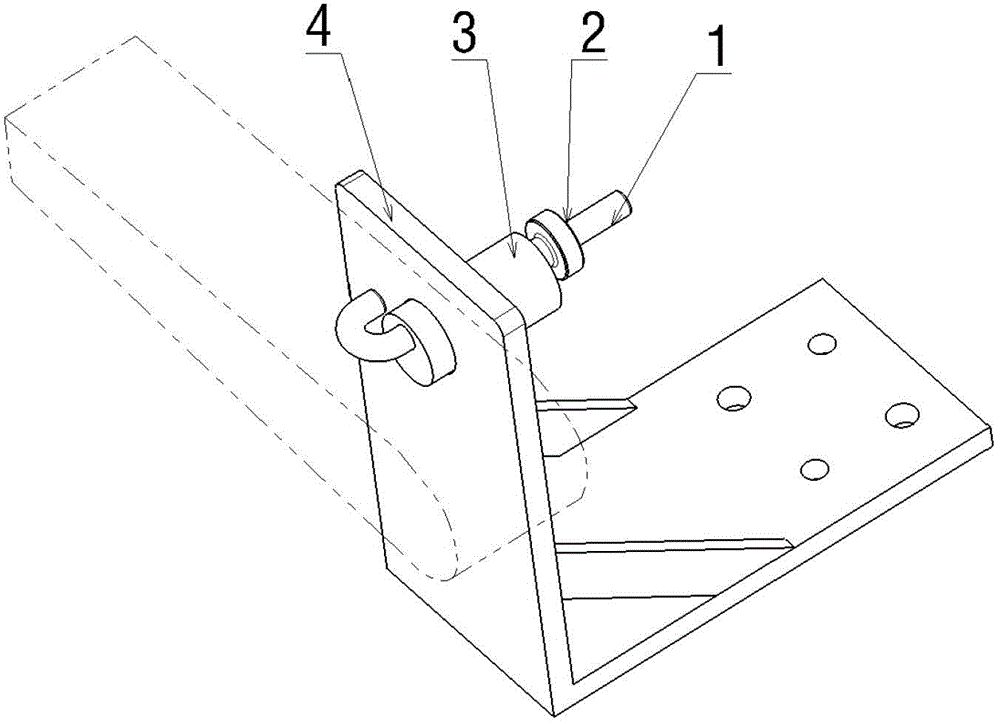

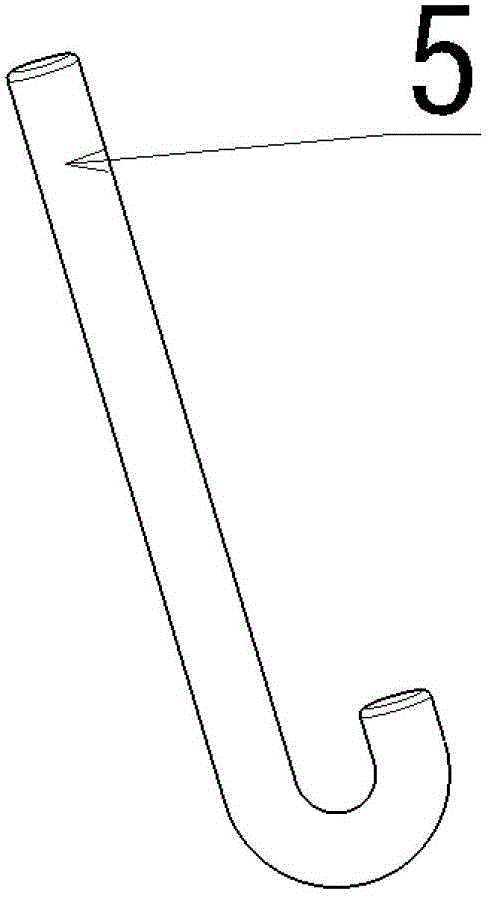

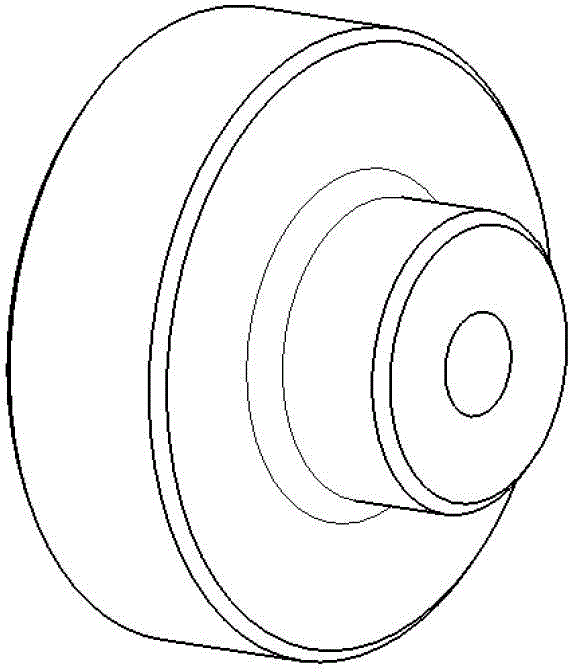

[0011] The present invention will be described in further detail below. See Figure 1~5 , A positioning compressor, composed of the following four basic parts: crimping hook 1, knurled nut 2, positioning shaft 3 and support 4; crimping hook 1 with assembly thread 5 at the tail; knurled nut 2 using standard The positioning shaft 3 is a shaft with a shoulder and an eccentric hole 6, and the support 4 is welded by two metal positioning plates 7, 8 and two reinforced metal plates 9, 10, where the bottom of the support is positioned The plate has two positioning holes 11 and two bolt mounting holes 12, and the upper part of the other metal positioning plate 7 of the support has a positioning hole 13.

[0012] The method of use of the present invention is: when in use, put the press hook 1 together with the positioning shaft 3 into the positioning hole 13 on the support, and then rotate the press hook 1 so that the press hook can be compressed and positioned on the metal positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com