Platform type measurement packing scale

A metered packaging, platform-type technology, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of inability to realize automatic packaging, hidden safety hazards for operators, affecting work efficiency, etc., to achieve compact structure, improve accuracy, work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described below in conjunction with the drawings.

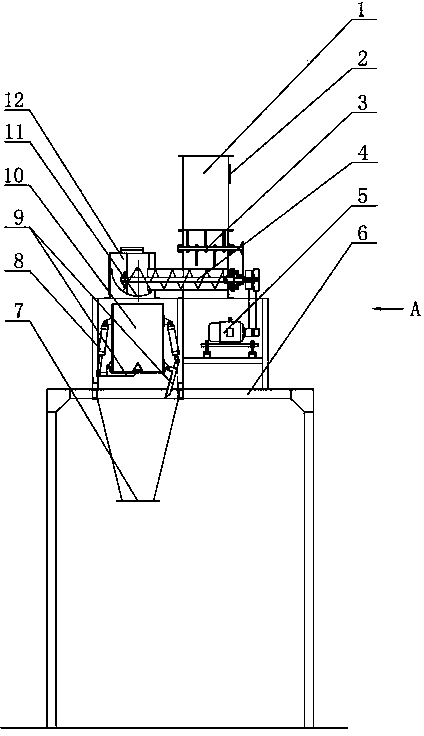

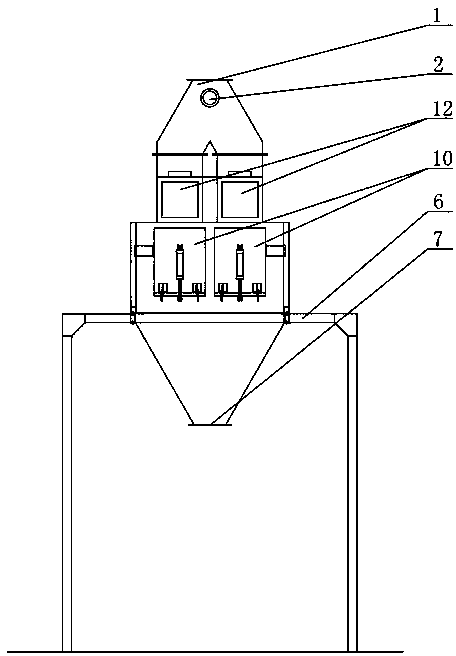

[0021] Such as figure 1 with figure 2 As shown, the platform-type metering packaging scale of this embodiment includes a frame 6, a hopper 1 is installed on the top of the frame 6, an arch breaking mechanism 3 is installed at the output end of the hopper 1, and an auger mechanism is installed at the lower part of the arch breaking mechanism 3 4. The auger mechanism 4 is driven by a power device. The output end of the auger mechanism 4 is connected with an arc door 11, the bottom of the arc door 11 is connected with a metering cylinder 10, and the bottom of the metering cylinder 10 is connected with a discharge cylinder 7. The barrel 7 is located at the bottom of the platform of the frame 6. The design of the arch breaking mechanism 3 effectively prevents the adhesive material from being transported smoothly.

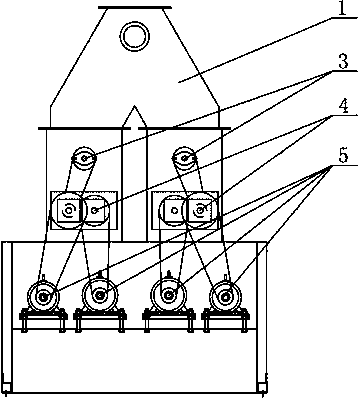

[0022] Such as figure 1 , figure 2 with image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com