Cross side dumping type variable-frequency drive conveying device for coal mines

A frequency conversion drive and conveying device technology, applied in the field of scraper conveyors, can solve the problems of no energy-saving features, and achieve the effects of convenient operation, reduced destructive force, and adjustable torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

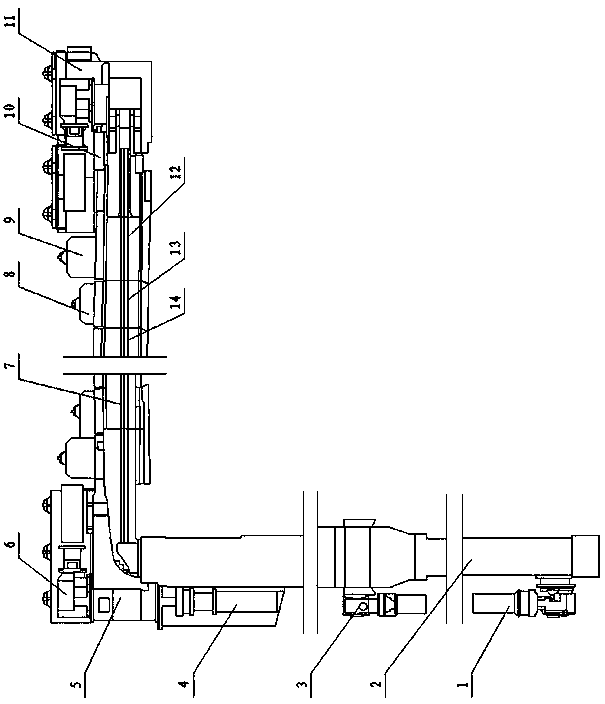

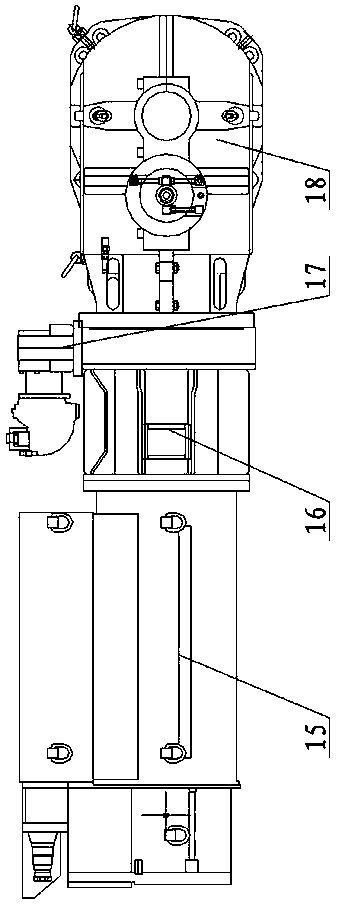

[0009] A cross-side unloading type frequency conversion drive conveying device for coal mines, including a scraper conveyor 5 and a scraper reloader, the scraper conveyor includes a conveyor head, a conveyor body 7 and a conveyor telescopic tail 11, The telescopic tail 11 of the conveyor is composed of a fixed frame body and a movable frame. A telescopic oil cylinder is arranged between the fixed frame body and the movable frame. A sprocket assembly is arranged at the front of the movable frame. Between the movable frame and the first deflection groove 14 of the telescopic conveyor tail, the second deflection groove 13 of the telescopic conveyor tail and the third deflection groove 12 of the telescopic conveyor tail arranged front and back, the conveyor The movable frame on the side of the second deflection slot 13 of the telescopic tail and the third deflection slot 12 of the conveyor telescopic tail is respectively equipped with a conveyor telescopic tail pushing device I8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com