Novel spring-weighted tension device

A tension device, a new type of technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems affecting the quality of winding yarn, small vibration of dynamic tension disc, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

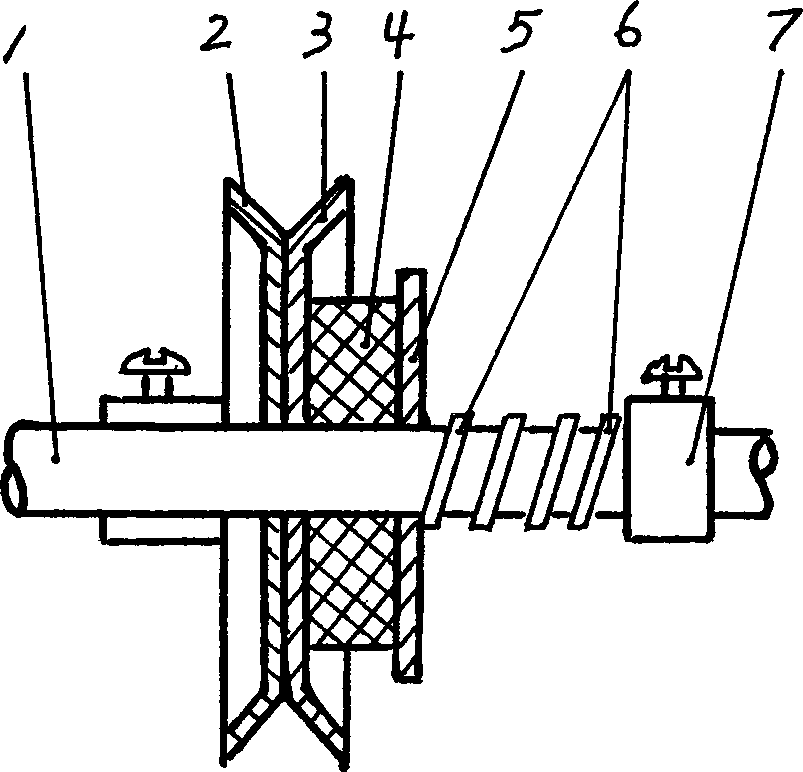

[0013] figure 1 Among them, the new spring-loaded tension device includes a guide rod 1, a static tension disc 2, a dynamic tension disc 3, a spring 6 and a tight ring 7, and the static tension disc 2 is fixed on the guide rod 1 with screws. The disc 3 is looped on the guide rod 1 and is set opposite to the static tension disc 2. The guide rod 1 is covered with a spring 6 and a tight ring 7, and the spring 6 is located between the dynamic tension disc 3 and the tight ring 7. And contact with the dynamic tension disc 3, the tight ring 7 is fixed on the guide rod 1 with screws, the cocoon cotton-like polyester fiber washer 4 is installed between the spring 6 and the dynamic tension disc 3, and the cocoon cotton-like polyester fiber The thickness of the gasket 4 is between 5mm and 8mm. A washer 5 is installed between the cocoon cotton-like polyester fiber washer 4 and the spring 6 to prevent the spring 6 from sinking into the cocoon-cotton-like polyester fiber washer. Cotton-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com