Adapter malfunction prevention protective system

A protection system and malfunctioning technology, applied in transportation and packaging, elevators, lifting equipment in mines, etc., can solve the problems of safety production threats, scraped cages, etc., to achieve low manufacturing costs, prevent scraping accidents, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

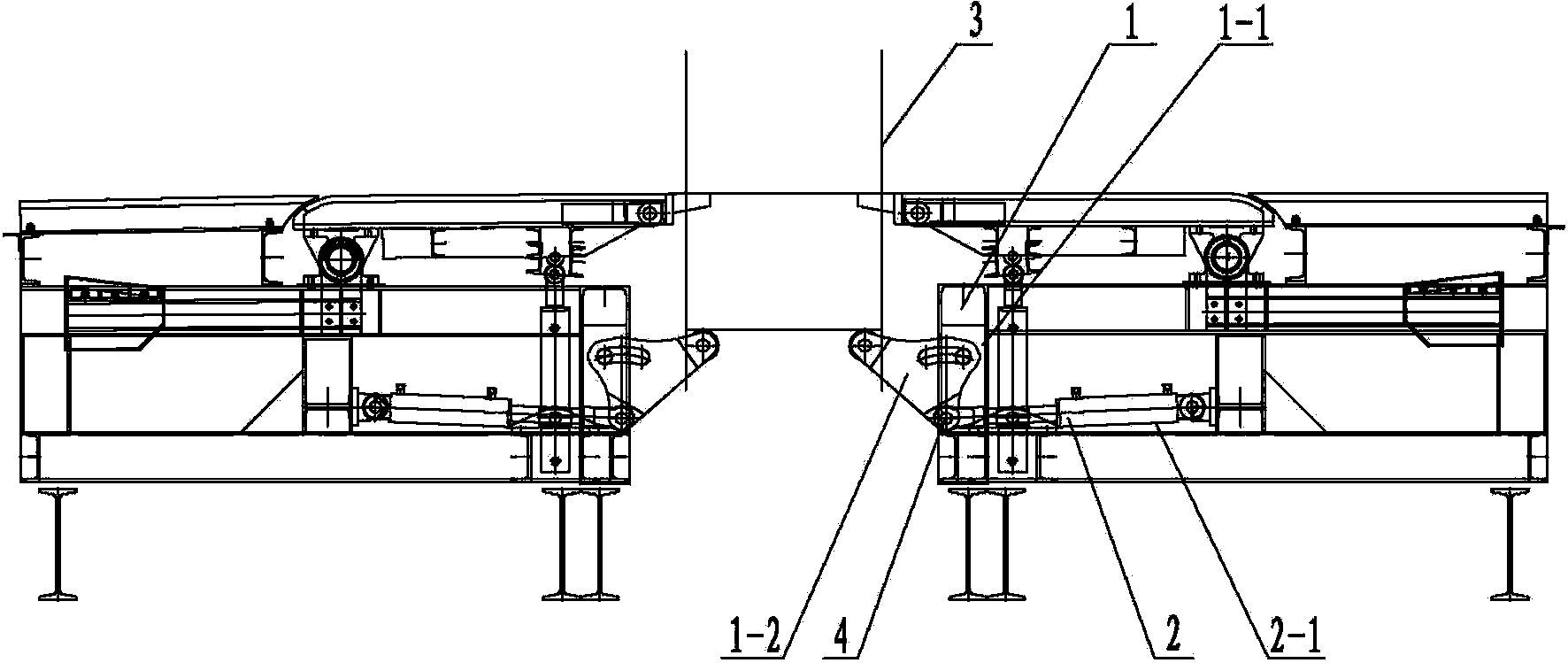

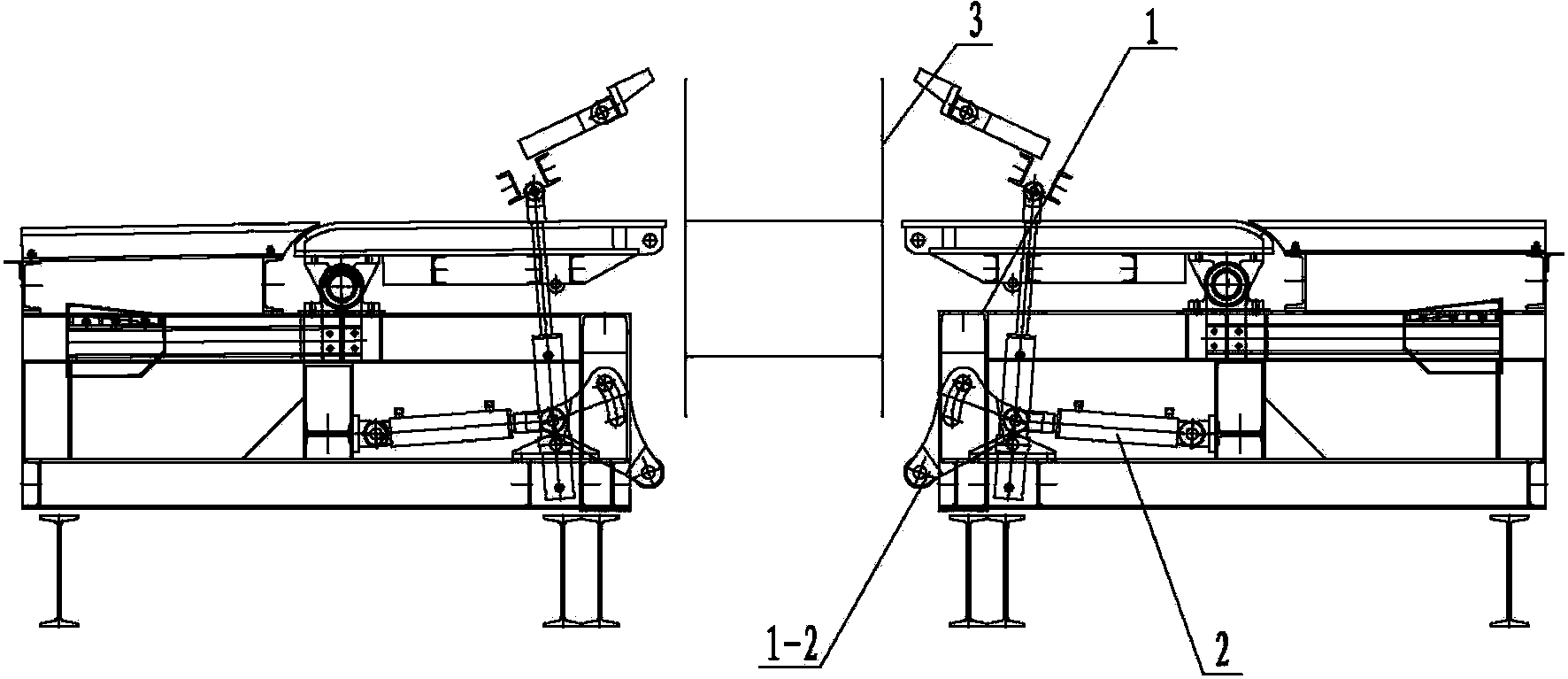

[0014] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a protection system for preventing misoperation of a receiving device, which is composed of a receiving device 1 and a hydraulic control system 2 and other parts.

[0015] Wherein, the receiving device 1 includes a frame 1-1 and a set of claws 1-2, and the set of claws 1-2 is pivotally connected to the frame 1-1. The receiving device 1 can receive the cage 3 .

[0016] The hydraulic control system 2 includes a hydraulic cylinder 2-1, a solenoid valve 2-2 and an oil tank 2-3; one end of the hydraulic cylinder 2-1 is welded on the frame 1-1, and the other end is connected by a connecting piece 4 and Drive supporting claw group 1-2, this hydraulic cylinder 2-1 is connected with oil tank 2-3 through electromagnetic valve 2-2.

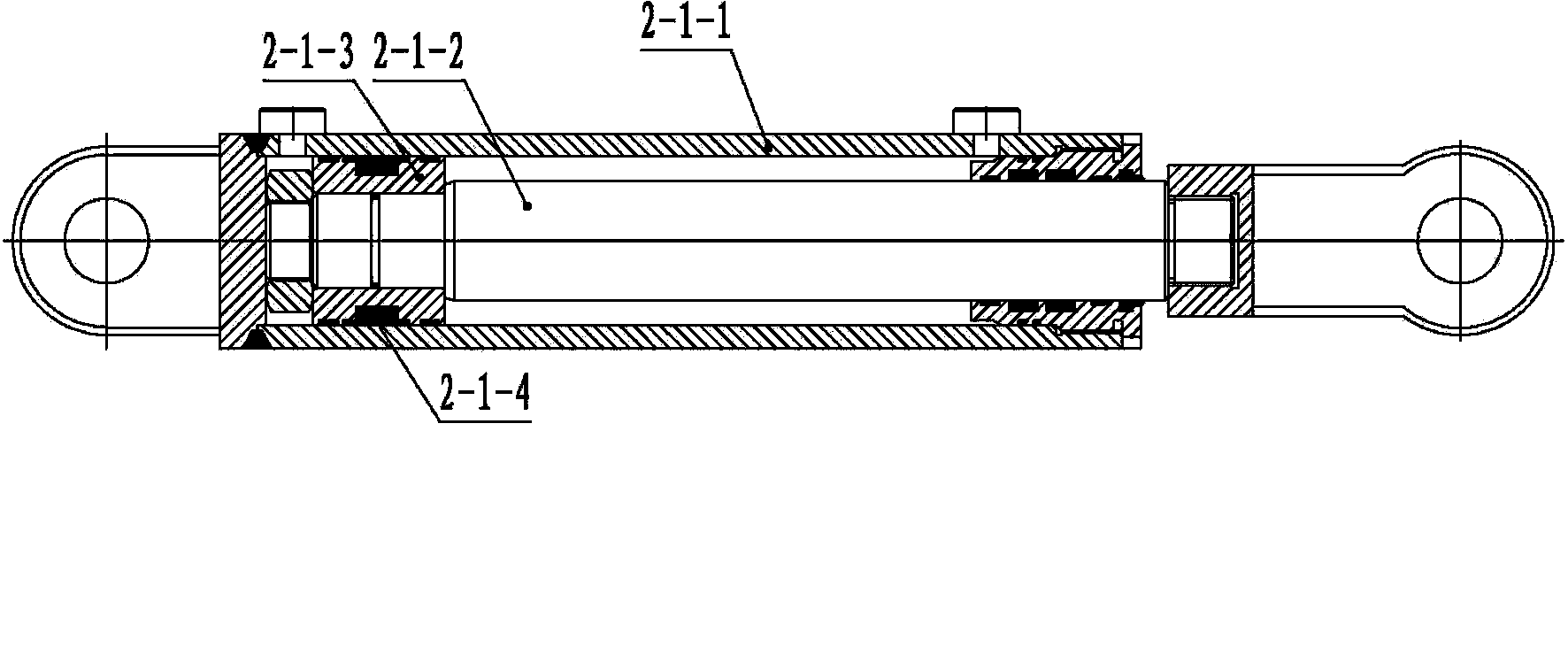

[0017] Further, the hydraulic cylinder 2-1 includes a cylinder body 2-1-1, a piston rod 2-1-2, a piston 2-1-3 and a sealing device 2-1-4; wherein, the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com